Temperature and humidity independent control type air conditioning system with high-temperature cold water pre-cooling

An independent control, air conditioning system technology, applied in air conditioning systems, heating and ventilation control systems, household refrigeration devices, etc., can solve problems such as limiting the energy efficiency level of the system, increasing the complexity of the system, and increasing the complexity of the system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

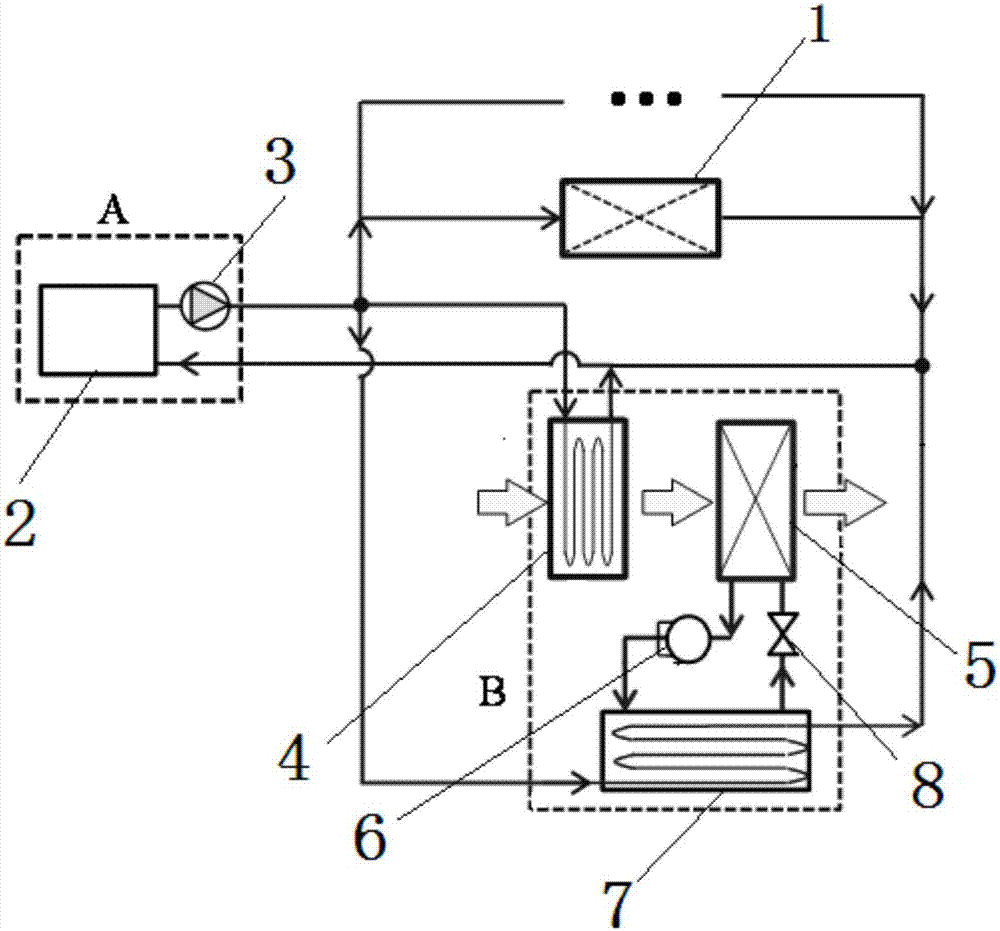

[0013] Such as figure 1 As shown, the present invention includes a high-temperature refrigeration station A, a sensible heat terminal 1 and an air dehumidification processing unit B, wherein the sensible heat terminal 1 and the air dehumidification processing unit B are arranged indoors. The high-temperature refrigeration station A includes a high-temperature chiller 2 and a chilled water pump 3 . The air dehumidification processing unit B includes a pre-cooling surface cooler 4 , an evaporator 5 , a compressor 6 , a water-cooling surface cooler 7 and a throttle valve 8 . Among them, the evaporator 5, the compressor 6, the water-cooled surface cooler 7 and the throttle valve 8 are sequentially connected to form a refrigerant circulation loop; the pre-cooling surface cooler 4 and the evaporator 5 are sequentially placed on the air channel to be dehumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com