Heating angle adjusting device for variable-cross-section stabilizer rod

An angle adjustment device and angle adjustment technology, applied in heat treatment furnaces, heat treatment equipment, heat treatment process control, etc., can solve problems such as low degree of automation, and achieve the effect of realizing automatic control, high angle adjustment precision, and saving manpower and material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

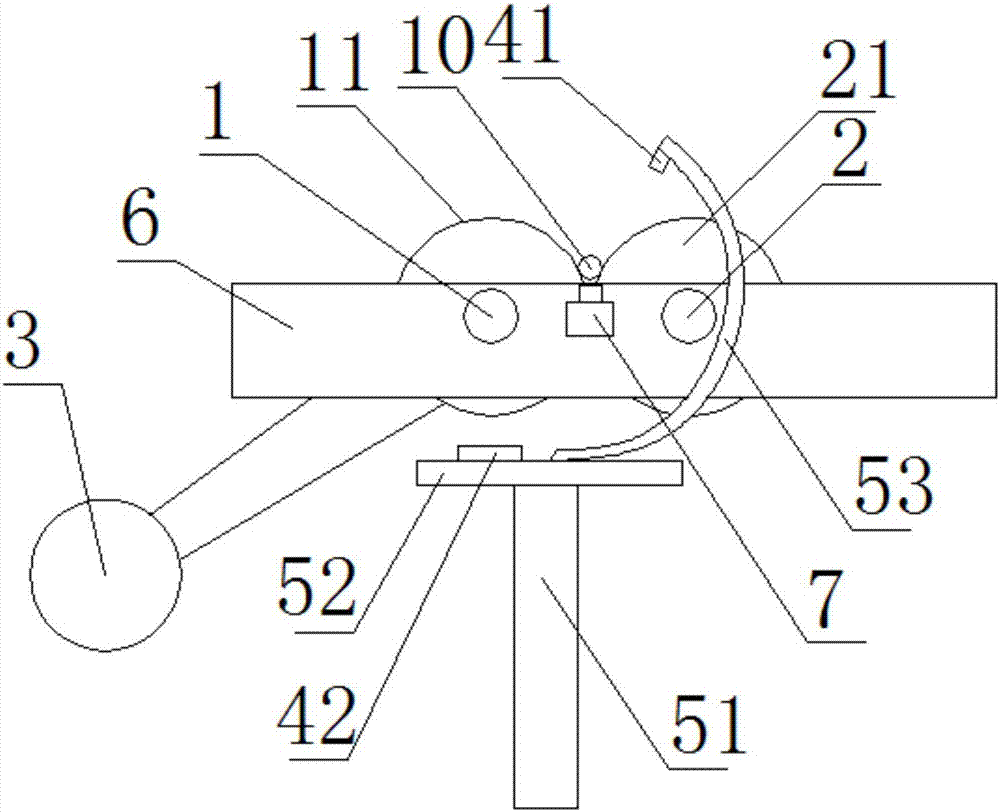

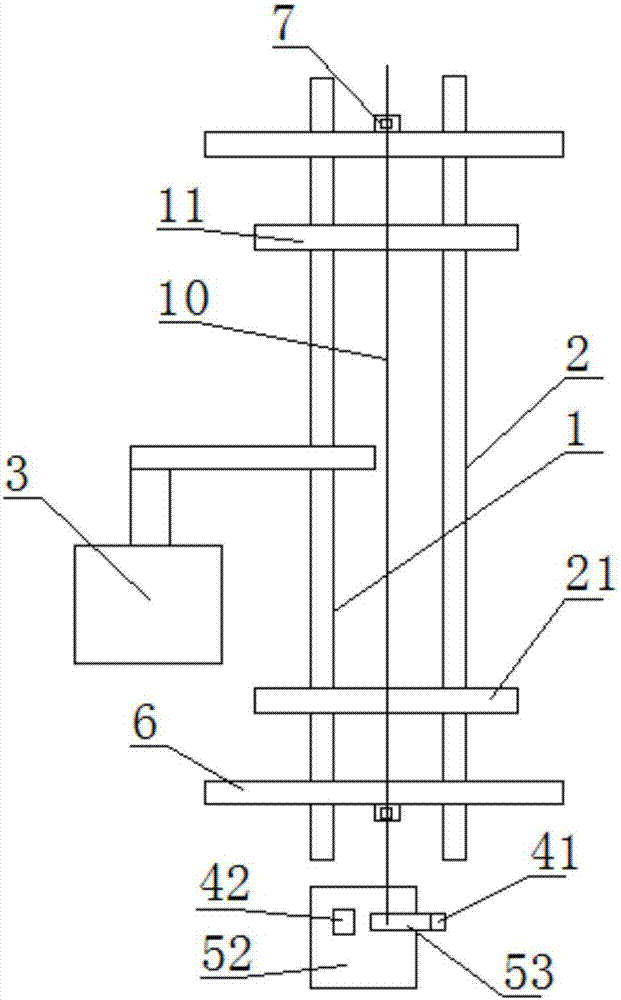

[0019] like figure 1 , figure 2 As shown, a heating angle adjustment device for a variable cross-section stabilizer bar, the end of the rod 10 is a variable cross section; the angle adjustment device for the rod detail includes an angle recognition mechanism, an angle adjustment mechanism, and a control mechanism; the control mechanism controls the angle adjustment mechanism to rotate the rod. The angle recognition mechanism senses the projected area at both ends of the rod. When the projected area reaches the set standard, the far-infrared sensor sends a stop message to the angle adjustment mechanism, and the angle adjustment mechanism stops working.

[0020] The angle adjustment mechanism includes a driving shaft 1, a driven shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com