Acrylics POSS-modified silicon dioxide nanoparticle-containing lubricating oil and preparation method thereof

A technology based on acrylate and silicon dioxide, which is applied in the field of lubricating oil, can solve the problems of poor anti-wear and anti-friction performance of lubricating oil, and achieve the effects of improving anti-gluing ability, enhancing anti-wear and anti-friction performance, and enhancing load-carrying performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

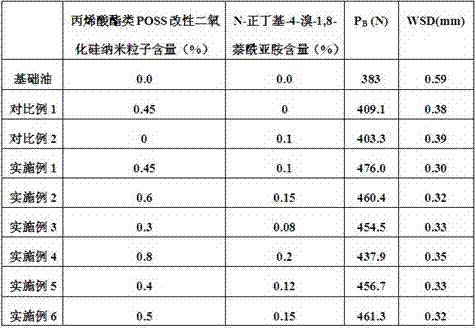

Embodiment 1

[0016] Add 0.45% of the weight of the base oil to the acrylate-based POSS modified silica nanoparticles into the base oil, mix evenly at 80-90°C; then cool down to room temperature, and add 0.1% of the weight of the base oil to N-n-butyl -4-bromo-1,8-naphthalimide and mix well.

Embodiment 2

[0018] Add 0.6% of acrylate POSS modified silica nanoparticles to the base oil and mix evenly at 80-90°C; then cool down to room temperature and add 0.15% of the weight of the base oil to N-n-butyl -4-bromo-1,8-naphthalimide and mix well.

Embodiment 3

[0020] Add 0.3% of acrylate POSS modified silica nanoparticles to the base oil, mix well at 80-90°C; then cool down to room temperature, add 0.08% of the base oil weight N-n-butyl -4-bromo-1,8-naphthalimide and mix well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com