A kind of silica airgel reflective heat insulation exterior wall coating and preparation method thereof

A technology for silica airgel and exterior wall coatings, which is applied in the direction of reflection/signal coatings, antifouling/underwater coatings, chemical instruments and methods, etc. It can solve the problems of difficult storage and construction of products, complex preparation process, and complicated process. , to achieve the effect of improving reflective heat insulation performance, increasing solar reflectance, and reducing heat conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~8

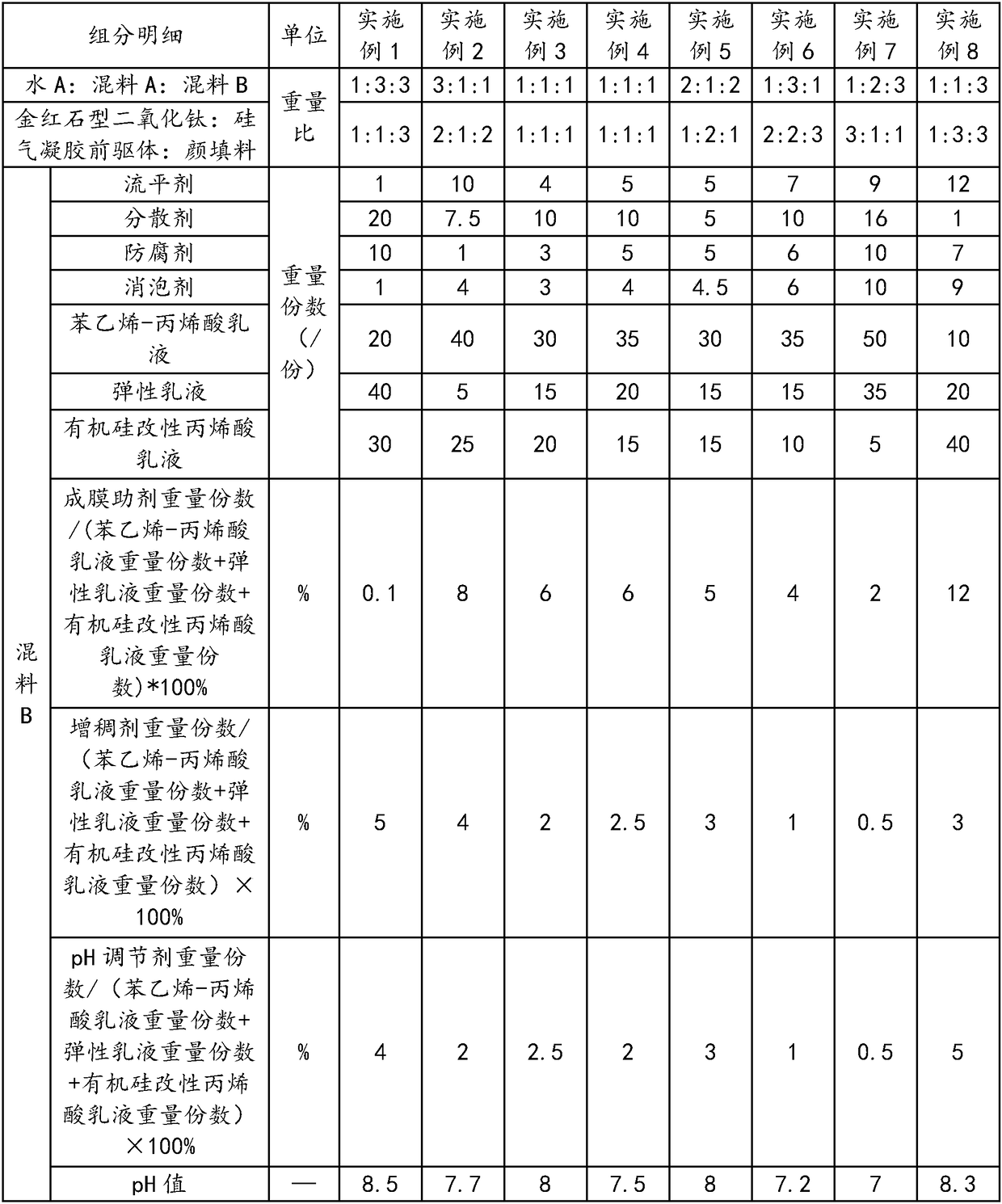

[0078] 1. A formula for airgel reflective and heat-insulating exterior wall coating, comprising water A, mixture A, and mixture B, in terms of weight ratio, water A: mixture A: mixture B=(1~3) :(1~3):(1~3);

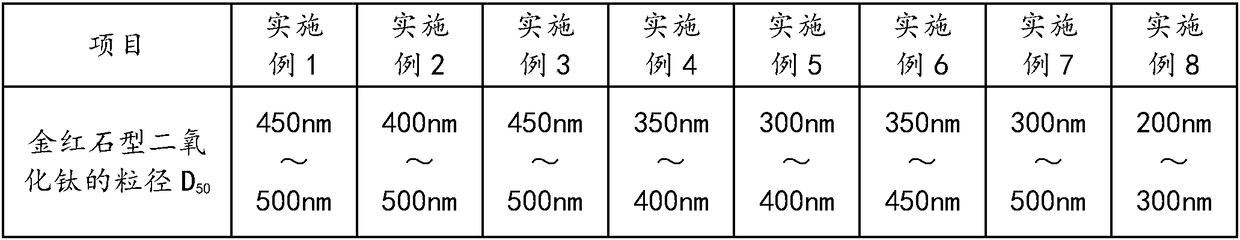

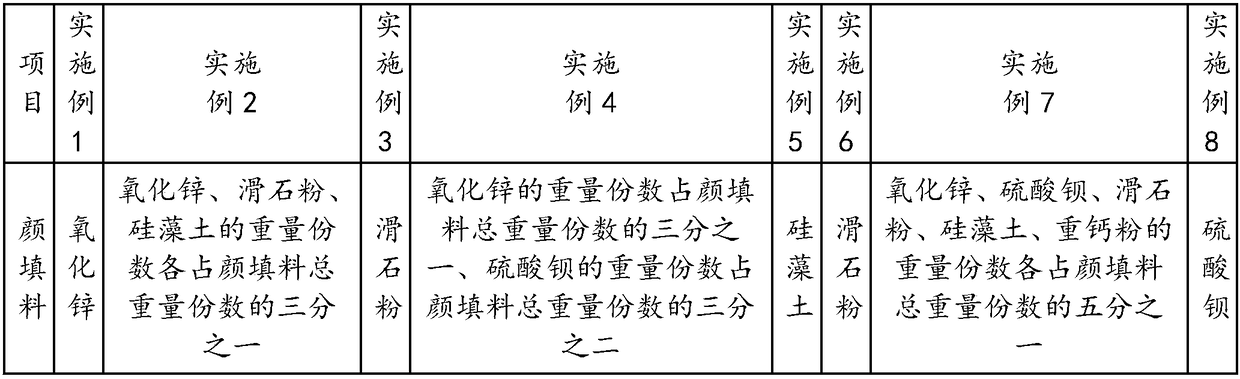

[0079] Mixture A includes rutile titanium dioxide, silica airgel precursor, pigment and filler, according to the weight ratio, rutile titanium dioxide:silica airgel precursor: pigment and filler=(1~3):(1~3):( 1~3);

[0080] Mixture B includes 1-12 parts by weight of leveling agent, 1-20 parts by weight of dispersant, 1-10 parts by weight of preservative, 1-10 parts by weight of defoamer, 10-10 parts by weight of 50 parts by weight of styrene-acrylic emulsion, 5-40 parts by weight of elastic emulsion, 5-40 parts by weight of silicone-modified acrylic emulsion, film-forming aids, thickeners, and pH regulators, with a pH value of 7-40 parts 8.5;

[0081] The parts by weight of the film-forming aid are 0.1 to 12% of the sum of the parts by weight of the styrene-acrylic emu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid containing ratio | aaaaa | aaaaa |

| aperture size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com