Novel red mud comprehensive utilization method

A new method and technology of red mud, applied in the direction of calcium/strontium/barium halides, alkali metal chlorides, alkali metal silicates, etc., can solve the problems of red mud not being effectively treated, low dosage, etc., and achieve energy consumption Less cost, low process cost, and the effect of solving land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

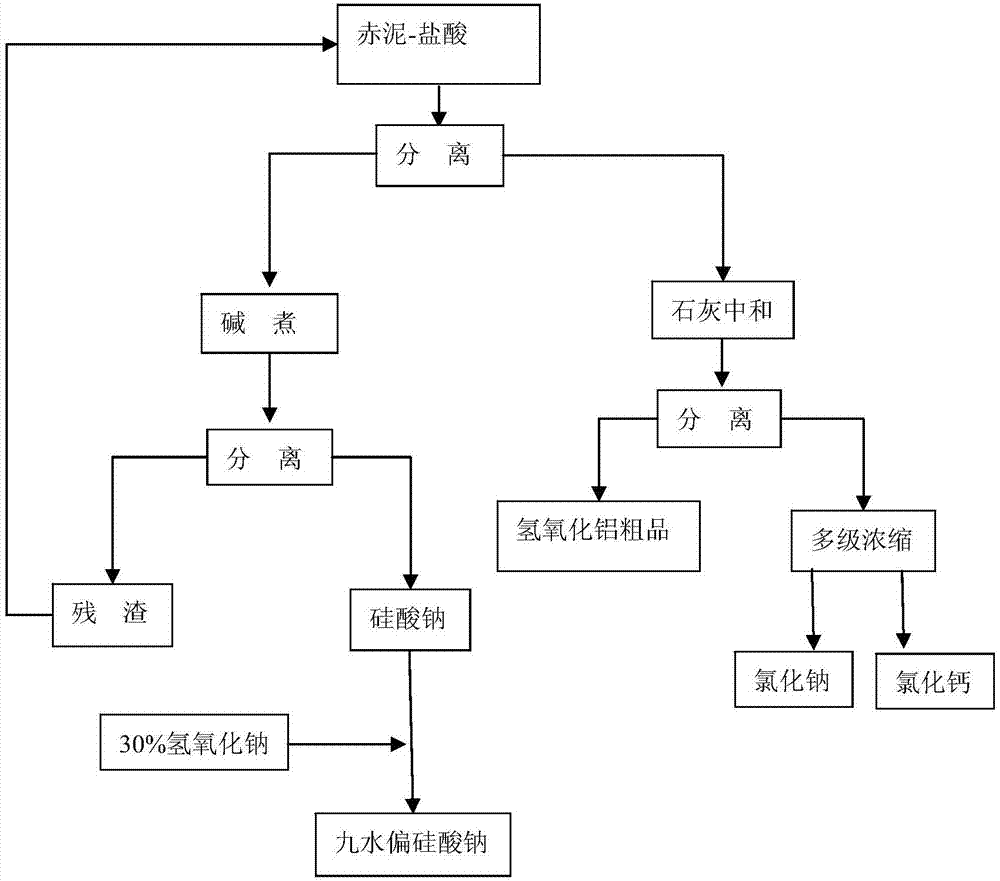

Method used

Image

Examples

Embodiment 1

[0023] Take 50 g of red mud dried and crushed to 180 mesh and put it into a three-necked flask, add 200 ml of 1:1 HCl (hydrochloric acid obtained by mixing 1 volume of concentrated hydrochloric acid with 1 volume of water, the concentration is about 6 mol / L), and heat to Boil, condense and reflux for 2h, then filter and separate to obtain filtrate 1 and filter residue 1. Separated filtrate 1 was added with 10% calcium hydroxide solution under constant stirring to adjust to neutrality, then separated by filtration and washed to obtain 38.5 g of aluminum hydroxide coarse residue and filtrate 2. Aluminum hydroxide coarse slag can be used as a raw material for the alumina plant to produce alumina. The filtrate two is concentrated and separated, and 7 g of sodium chloride with higher purity is first crystallized, and then concentrated to obtain 32 g of calcium chloride. Calcium chloride can be used as a deicing agent.

[0024] Wash the filter residue 1 with water until neutral, t...

Embodiment 2

[0026] In the ceramic reactor, add 6m 3 1:2HCl (hydrochloric acid obtained by mixing 1 volume of concentrated hydrochloric acid and 2 volumes of water, the concentration is about 4mol / L), under constant stirring, slowly add 1t of dry red mud crushed to 120 mesh, heat to boiling, condense and reflux for 3h , separating the solid and liquid to obtain the acid-treated solid residue and filtrate.

[0027] For the separated filtrate, milk of lime is continuously added under continuous stirring to adjust the solution to neutrality. Separating and washing to obtain coarse slag of aluminum hydroxide, which is sent to an alumina plant as a raw material to produce alumina. The filtrate is concentrated and separated in multiple stages, and sodium chloride and calcium chloride are respectively prepared according to the crystallization sequence to be used as deicing agent.

[0028] The solid filter residue after acid treatment is separated and washed to neutrality, and 0.25t of sodium h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com