An automatic replacement fluorescent tube drone

A fluorescent tube, automatic replacement technology, applied in the directions of manipulators, rotorcraft, motor vehicles, etc., can solve the problems of life safety, limited life of fluorescent lamps, troubles, etc., to achieve fast moving speed, reduce safety hazards, and expand the scope of work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

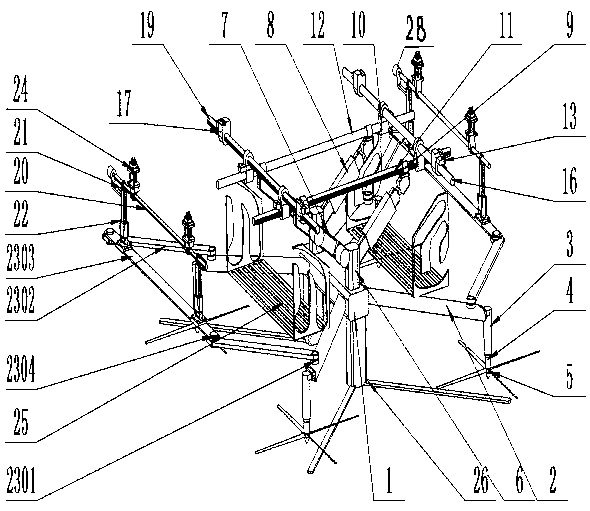

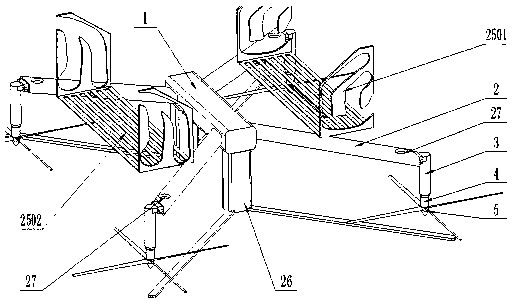

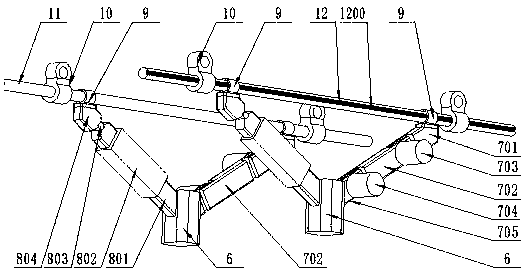

[0030] Such as Figures 1 to 12 As shown, an unmanned aerial vehicle for automatically replacing fluorescent tubes includes a body 1, a machine arm 2, a motor extension shaft 3, a first motor 4, a propeller 5, a column 6, a mechanical arm 7, a first joint 701 of a mechanical arm, and a mechanical arm Second joint 702, second main motor 703, second auxiliary motor 704, mechanical arm fixed arm 705, first electric cylinder 8, first electric cylinder fixed shaft 801, first electric cylinder cylinder body 802, hinge shaft 803, hinge Auxiliary end 804, first shaft connection element 9, conversion bushing 10, first straight shaft 11, second straight shaft 12, second straight shaft spur rack 1200, third motor fixing seat 13, third motor 14, first straight shaft Three motor gears 15, first horizontal straight shaft left shaft 16, first horizontal straight shaft straight rack 1601, mobile console 17, rectangular protruding button 18, first horizontal straight shaft right shaft 19, second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com