Manufacturing method of flip-flop lace

A manufacturing method and technology for flip-flops, which are applied in the field of slippers, can solve the problems of affecting the appearance of flip-flops, no bumpy feeling, poor 3D effect, etc., and achieve the effects of strong bumpy feeling, easy operation and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

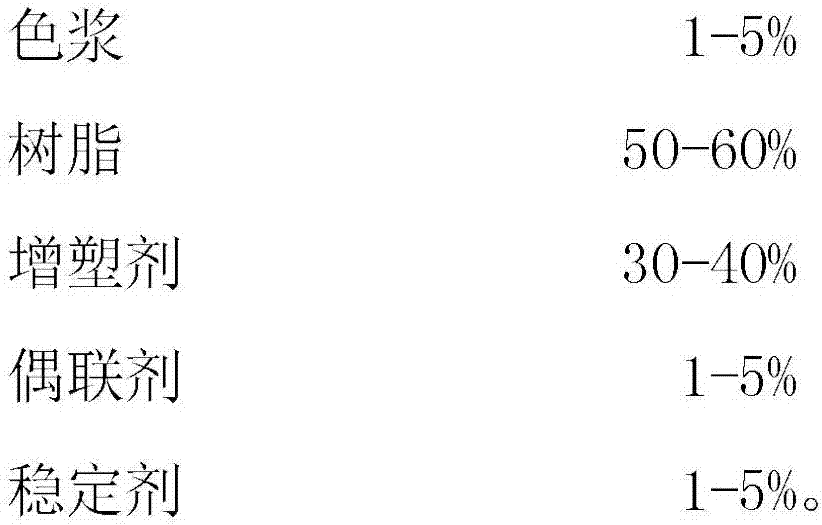

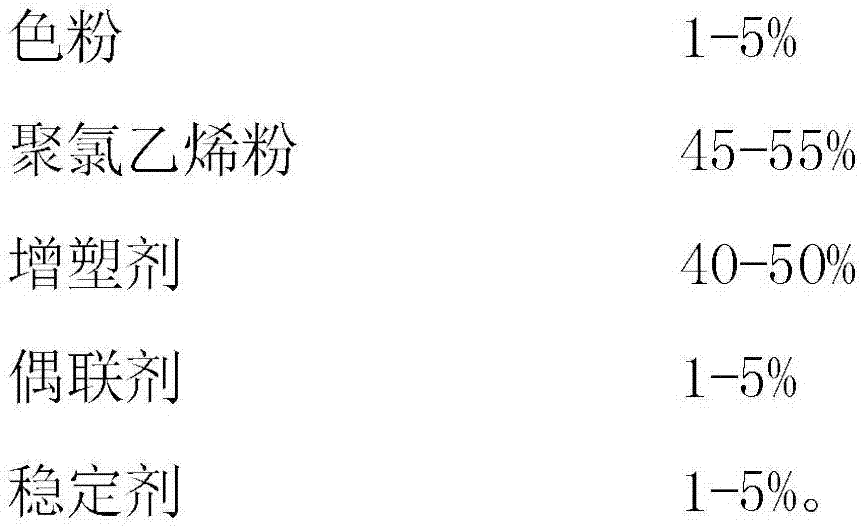

[0024] A kind of manufacturing method of flip-flop strap of the present embodiment, comprises the following steps:

[0025] Glue dispensing: Put the lower mold of the flip-flop strap into the glue dispenser, and use the glue dispenser to dispense glue into the cavity of the lower mold of the flip-flop strap to form a preset pattern;

[0026] Thermoforming: Put the lower mold of the flip-flop strap into the drying equipment for heating and forming to solidify the pattern;

[0027] Injection molding: Put the lower mold of the flip-flop strap into the injection molding machine, close the upper mold of the flip-flop strap, make the cavity of the upper mold of the flip-flop strap match the cavity of the lower mold of the flip-flop strap, through injection molding The machine injects plastic into the cavity of the upper mold of the flip-flop strap and the cavity of the lower mold of the flip-flop strap, and the plastic is formed on the upper surface of the cured pattern;

[0028] M...

Embodiment 2

[0041] A kind of manufacturing method of flip-flop strap of the present embodiment, comprises the following steps:

[0042] Glue dispensing: Put the lower mold of the flip-flop strap into the glue dispenser, and use the glue dispenser to dispense glue into the cavity of the lower mold of the flip-flop strap to form a preset pattern;

[0043] Thermoforming: Put the lower mold of the flip-flop strap into the drying equipment for heating and forming to solidify the pattern;

[0044] Injection molding: Put the lower mold of the flip-flop strap into the injection molding machine, close the upper mold of the flip-flop strap, make the cavity of the upper mold of the flip-flop strap match the cavity of the lower mold of the flip-flop strap, through injection molding The machine injects plastic into the cavity of the upper mold of the flip-flop strap and the cavity of the lower mold of the flip-flop strap, and the plastic is formed on the upper surface of the cured pattern;

[0045] M...

Embodiment 3

[0059] A kind of manufacturing method of flip-flop strap of the present embodiment, comprises the following steps:

[0060] Glue dispensing: Put the lower mold of the flip-flop strap into the glue dispenser, and use the glue dispenser to dispense glue into the cavity of the lower mold of the flip-flop strap to form a preset pattern;

[0061] Thermoforming: Put the lower mold of the flip-flop strap into the drying equipment for heating and forming to solidify the pattern;

[0062] Injection molding: Put the lower mold of the flip-flop strap into the injection molding machine, close the upper mold of the flip-flop strap, make the cavity of the upper mold of the flip-flop strap match the cavity of the lower mold of the flip-flop strap, through injection molding The machine injects plastic into the cavity of the upper mold of the flip-flop strap and the cavity of the lower mold of the flip-flop strap, and the plastic is formed on the upper surface of the cured pattern;

[0063] M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com