Through-flow turbine water guide mechanism internal and external ring coaxial processing equipment and processing method

A technology of tubular water turbine and water guiding mechanism, which is applied in the direction of metal processing equipment, precision positioning equipment, drilling/drilling equipment, etc. It can solve the problems of inability to process, poor processing accuracy, hidden safety hazards, etc., and achieve automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

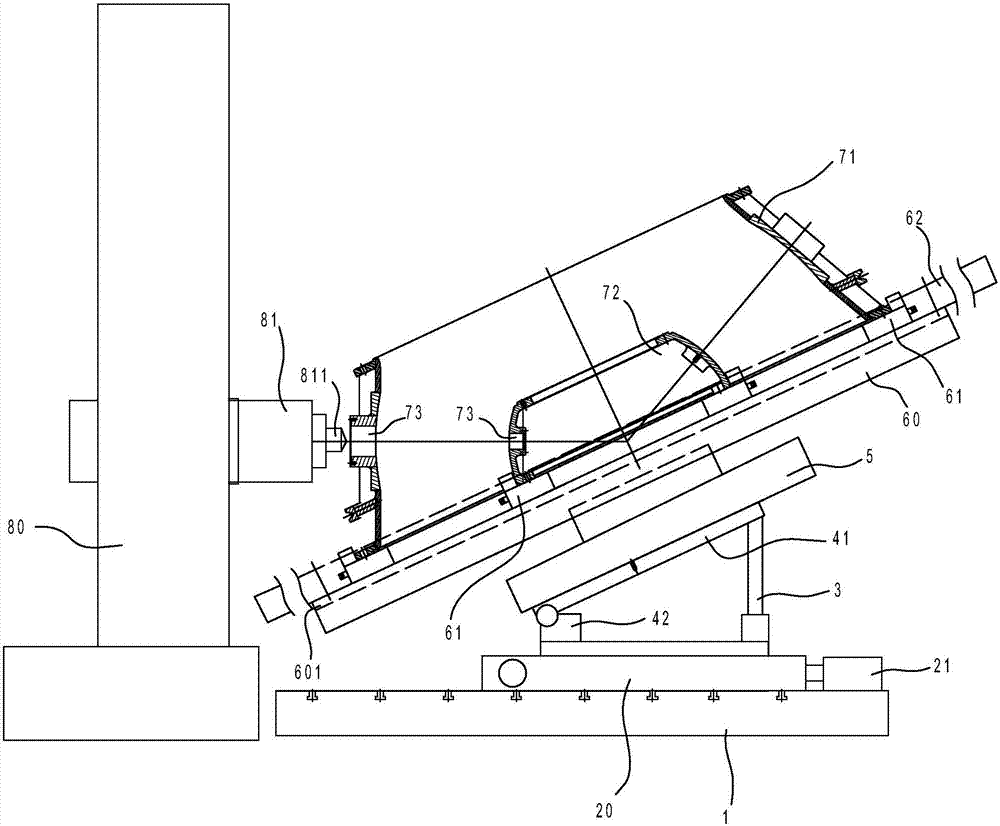

[0023] Such as figure 1 As shown, the coaxial processing equipment for the inner and outer rings of the water guide mechanism of the tubular water turbine in this implementation includes a base 1, a sliding cylinder 21, a numerically controlled indexing plate 20, a tilting cylinder 3, a jacking cylinder 5, a connecting plate 51, and a hinge block 42, installation plate 60, extension frame 61, column 80, numerical control knife rest 81 and controller.

[0024] Wherein, the base 1 is provided with a slide cylinder 21, the base 1 is provided with a chute, the chute is provided with a numerical control indexing plate 20, and the numerical control indexing plate 20 is connected with the output end of the sliding cylinder 21, A connecting plate 41 and a tilting cylinder 3 are arranged on the top of the numerically controlled indexing plate 20, one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com