A Modified Analysis Method of Gear Pair Meshing Characteristics Considering Drum Modification

A characteristic analysis and gear pair technology, applied in special data processing applications, instruments, geometric CAD, etc., can solve problems such as high computer performance requirements, complex modeling process, and large calculation result errors, and meet computer performance requirements The effect of low, simple modeling process, and small result error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

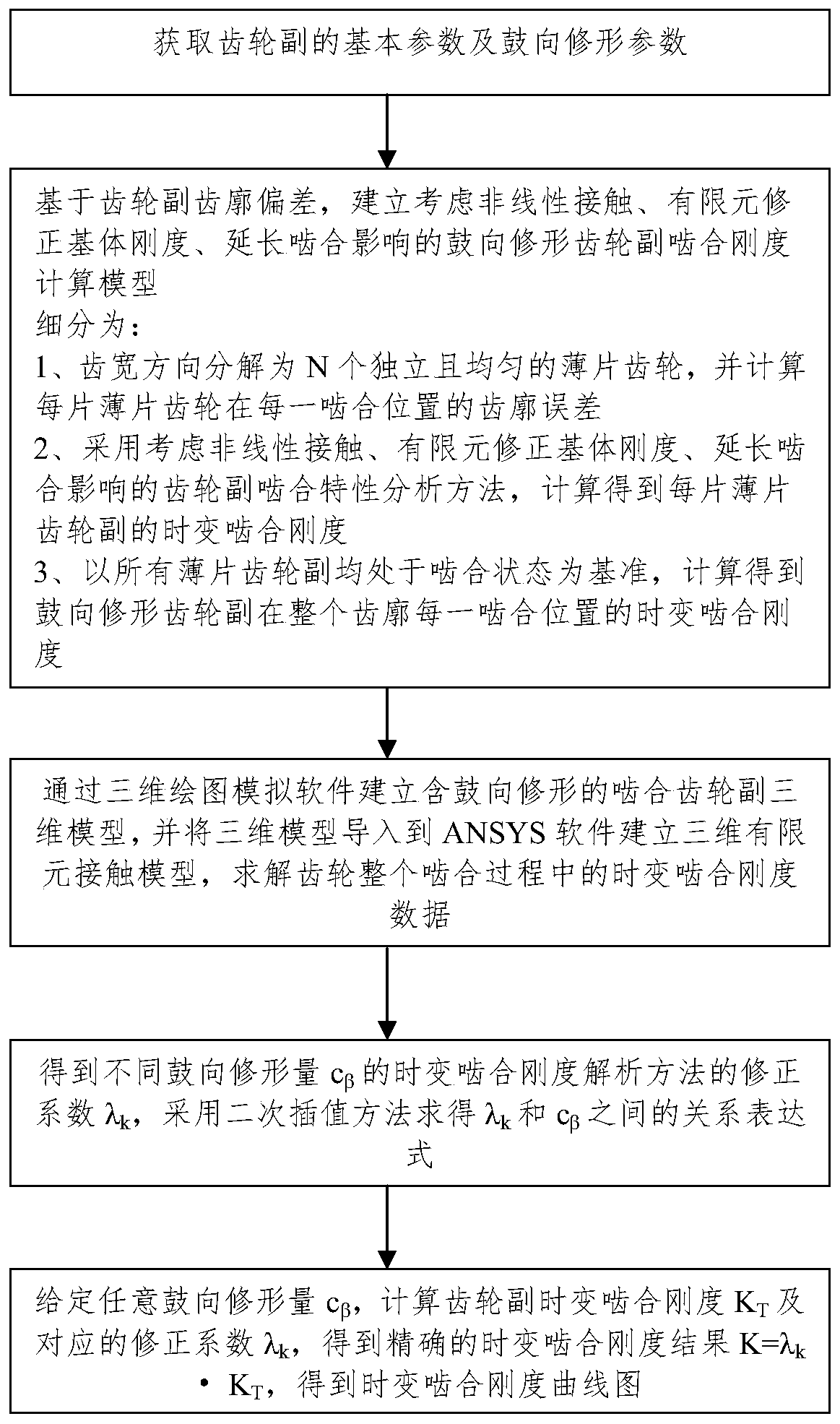

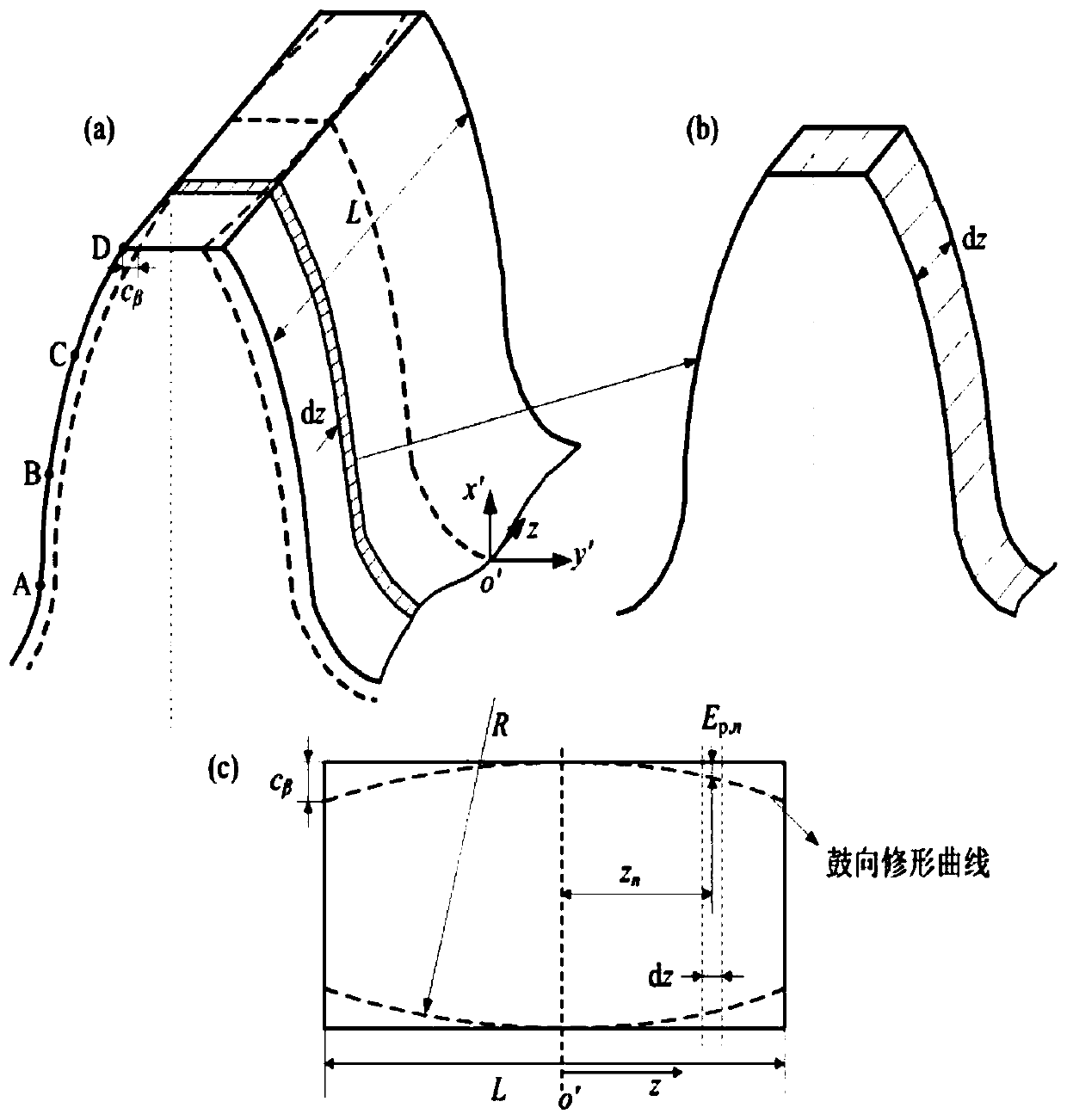

[0057] Such as figure 1 Shown: This embodiment discloses a modified method for analyzing the meshing characteristics of a gear pair considering the bulging modification, which includes the following steps:

[0058] S1: Obtain the basic parameters of the gear pair and the modification parameters of the drum direction;

[0059] In this embodiment, the basic parameters of the acquired gear pair and the modification parameters of the drum direction are shown in Table 1:

[0060] Table 1 The basic parameters of the drum-shaped modified gear pair

[0061]

[0062]

[0063] In this embodiment, the drum-direction modification amount is 0-20 μm, and it is expected to quickly obtain the time-varying meshing stiffness of the gear pair at any drum-direction modifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com