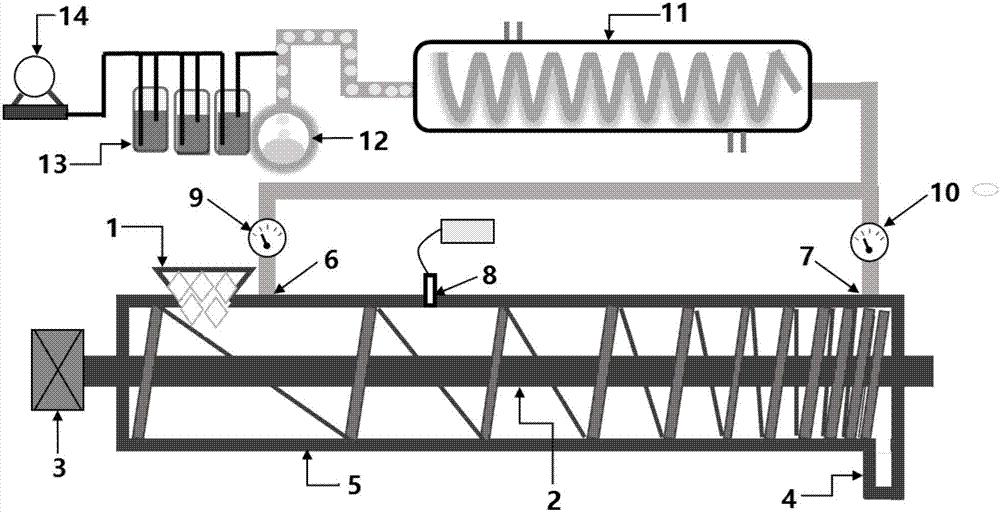

Device for producing oil by carrying out pyrolysis on polystyrene foam plastics

A foam plastic and polystyrene technology, applied in the field of waste recycling, can solve the problems of high quality raw materials, difficulty in continuous feeding, inconvenient transportation, etc., and achieve the effects of easy operation and maintenance, reduced emissions, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Styrofoam was treated using the above-mentioned apparatus. The styrofoam was taken from a supermarket bin and had not been washed. The polystyrene foam is put into the reaction device after crushing, and the feed load is 5kg-polystyrene foam / m 3 - barrel volume h. The temperature of the reaction device was controlled at 450°C by an electromagnetic induction thermostat. The residence time of polystyrene foam in the reaction device is 1h. The distance between the detection hole and the feeding port is 1 / 10 of the barrel length, and the distance between the top air guide tube and the feeding port is 1 / 15 of the barrel length. The vacuum in the tip airway circuit is 50 times the vacuum in the terminal airway circuit. Under the above operating conditions of the device, the polystyrene foam cracking rate is 45%, and the concentration of styrene in the condensed crude styrene solution is 65%.

Embodiment 2

[0034] The same device as in Example 1 was used, and the temperature of the reaction device was controlled at 500° C. by an electromagnetic induction thermostat. The residence time of polystyrene foam in the reaction device is 2h. Other conditions are identical with embodiment 1. According to the above operating conditions, the polystyrene foam cracking rate is 75%, and the concentration of styrene in the condensed crude styrene solution is 70%.

Embodiment 3

[0036] The same device as in Example 1 was used, and the temperature of the reaction device was controlled at 550° C. by an electromagnetic induction thermostat. Other conditions are identical with embodiment 2. According to the above operating conditions, the polystyrene foam cracking rate was 90%, and the concentration of styrene in the condensed crude styrene solution was 68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com