Multi-rolling-needle pitch circle fixture for gear welding and application method thereof

A technology for welding gears and needle rollers, which is applied to gear tooth manufacturing devices, belts/chains/gears, gear teeth, etc., and can solve the problems of poor tooth accuracy, machining, and radial runout, so as to meet production needs and improve Flexible, convenient and quick loading and unloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in further detail below in conjunction with accompanying drawing:

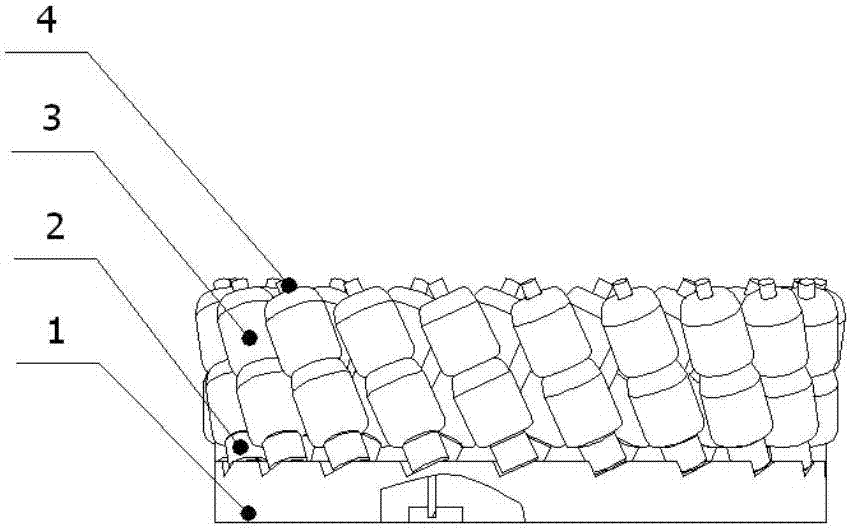

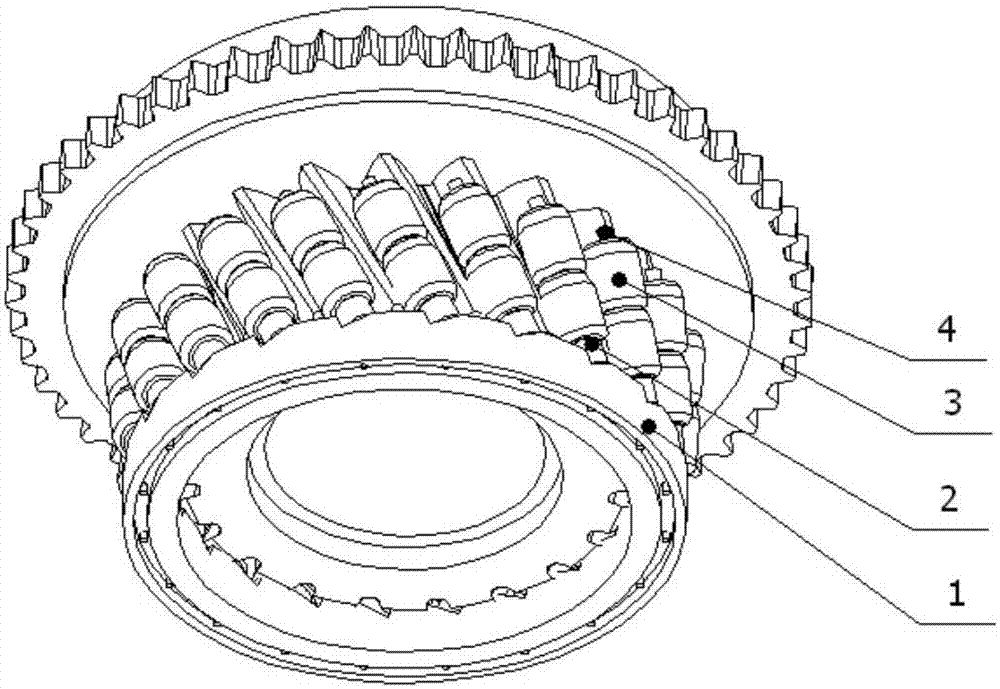

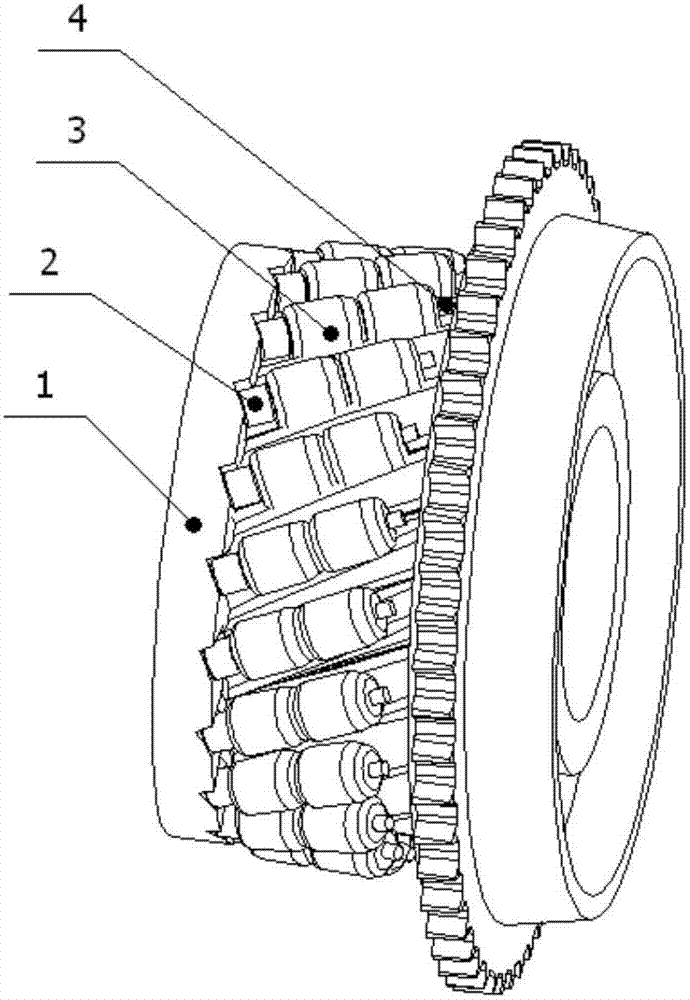

[0029] see figure 1 and figure 2 , The multi-needle pitch circle fixture for welding gears of the present invention can improve the precision of the teeth of the welded parts and avoid the blocking of one side of the welding gear, increase the positioning area, and quickly position and clamp. It includes support ring 1, bushing 2, pitch circle needle roller 3 and riveting steel wire 4. Specifically, a bushing 2 and two pitch circle needle rollers 3 are fixed on an inclined surface of support ring 1 through riveting steel wire 4, so After analogy, solder on the bottom surface of the support ring to complete the fixing of all bushes and pitch needle rollers. Wherein the supporting ring 1 is processed with the same inclined surface and the through hole of φ1mm as the number of positioning gears. The inclination angle of the inclined surface of the support ring 1 is th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com