Precision electrical appliance control cabinet

An electrical control cabinet, sophisticated technology, applied in the direction of electrical equipment shell/cabinet/drawer, static electricity, electrical components, etc., can solve the problems of difficult to control the cabinet, adjust to the right position, large size and weight of the control cabinet, save labor The effect of safety and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

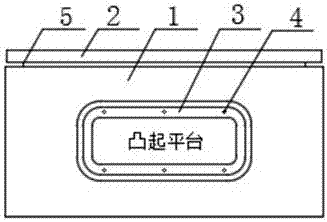

[0015] A precision electrical control cabinet, comprising a main cabinet panel 1, an installation fixture 2 and a raised platform 3; the installation fixture 2 is connected to the upper end surface of the main cabinet panel 1 by installing and fixing a connecting rod 5; the raised The platform 3 is arranged at the middle of the front of the main cabinet body panel 1 through the fixing buckle 4; The inner layer is provided with a reinforced core board layer; the reinforced core board is extruded with a shaped board layer; the shaped board layer is extruded with an antistatic layer; the antistatic layer is extruded with a layer of anti-corrosion layer A layer of antistatic film is extruded on the surface of the antistatic layer; the antistatic film has the following raw materials in parts by weight: silicon micropowder accounts for 18 parts, titanium dioxide accounts for 3 parts, curing agent accounts for 1 part, polyethylene glycol 2 parts and ethoxylated alkyl ammonium sulfate...

Embodiment 2

[0017] The above-mentioned precision electrical control cabinet includes a main cabinet panel 1, an installation fixture 2 and a raised platform 3; the installation fixture 2 is connected to the upper end surface of the main cabinet panel 1 by installing and fixing a connecting rod 5; The lifting platform 3 is arranged on the front middle of the main cabinet body panel 1 through the fixing buckle 4; The inner layer is provided with a reinforced core board layer; the reinforced core board is extruded with a shaped board layer; the shaped board layer is extruded with an antistatic layer; the antistatic layer is extruded with a layer of anti-corrosion layer ; The surface of the antistatic layer is extruded into a layer of antistatic film; the antistatic film has the following raw materials in parts by weight: silicon micropowder accounts for 22 parts, titanium dioxide accounts for 5 parts, curing agent accounts for 4 parts, polyethylene glycol 5 parts and ethoxylated alkyl ammoni...

Embodiment 3

[0019] The above-mentioned precision electrical control cabinet includes a main cabinet body panel 1, an installation fixture 2 and a raised platform 3; the installation fixture 2 is connected to the upper end surface of the main cabinet body panel 1 by installing and fixing a connecting rod 5; The raised platform 3 is arranged in the middle of the front of the main cabinet body panel 1 through the fixing buckle 4; the main cabinet body panel 1 includes a reinforced core board, a shaping board, an anti-corrosion board and an anti-static layer; the main cabinet body panel The innermost layer is provided with a reinforced core board layer; the reinforced core board is extruded with a layer of shaped board layer; the shaped board layer is covered with an anti-static layer; the anti-static layer is extruded with a layer of anti-corrosion layer; the surface of the antistatic layer is extruded with a layer of antistatic film; the antistatic film has the following raw materials in par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com