Knowledge-based part parameterized modeling method for automobile welding jig

A technology for automobile welding fixtures and parametric modeling, which is applied in the fields of knowledge expression, electrical digital data processing, special data processing applications, etc. And reuse, consuming a lot of manpower and energy, etc., to achieve the effect of being conducive to circulation and sharing, shortening the development cycle, and rapid model establishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

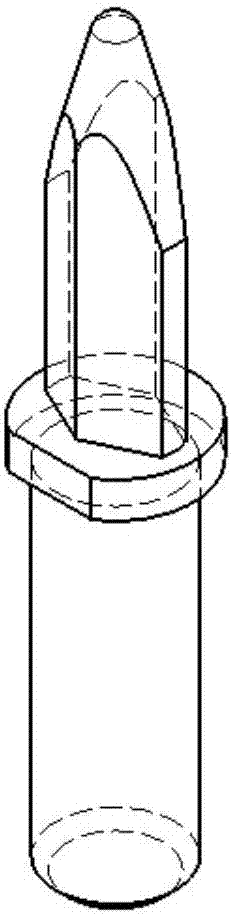

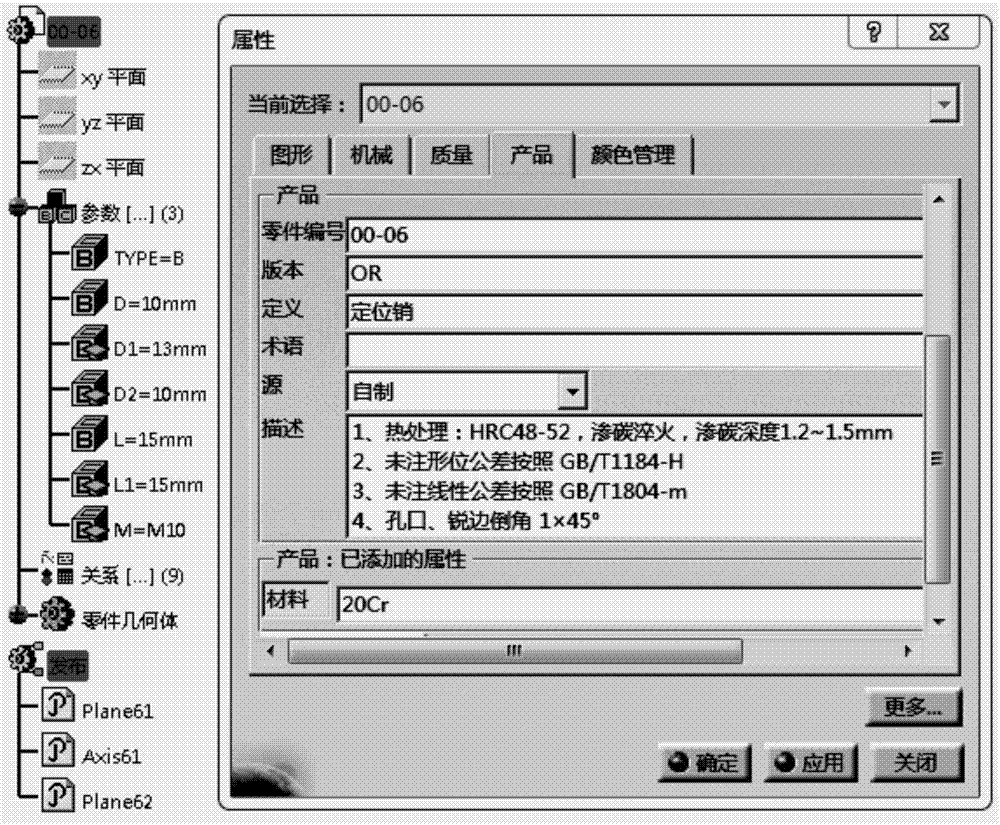

[0031] Embodiment 1 Taking an automobile welding fixture part model as an example, the knowledge-based parametric modeling method for automobile welding fixture parts of the present invention includes the following steps:

[0032] A. Extract design knowledge for welding fixture parts. Design knowledge includes design technical specification knowledge and design process knowledge. Design technical specification knowledge includes part selection specification, assembly method between parts, part technical requirements and part structure design specification, design process Knowledge includes part model parameter knowledge and design experience knowledge. Part model parameter knowledge is to extract parameters for each fixture part. The parameters include main control parameters, auxiliary parameters and other parameters. The main control parameters determine the main dimensions of the part model. The parameters determine the relationship between some part model features and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com