Well structure design and method for exploiting geothermal energy and gas hydrate reservoir at the same time of water injection

A hydrate and geothermal energy technology, which can be used in heating devices, other non-combustion heat generation, and production of fluids, etc., can solve the problems of not proposing natural gas hydrate reservoirs, restricting the development and utilization of natural gas hydrate reservoirs, etc., achieving convenient operation, Simple and economical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings, but the implementation scope of the present invention is not limited.

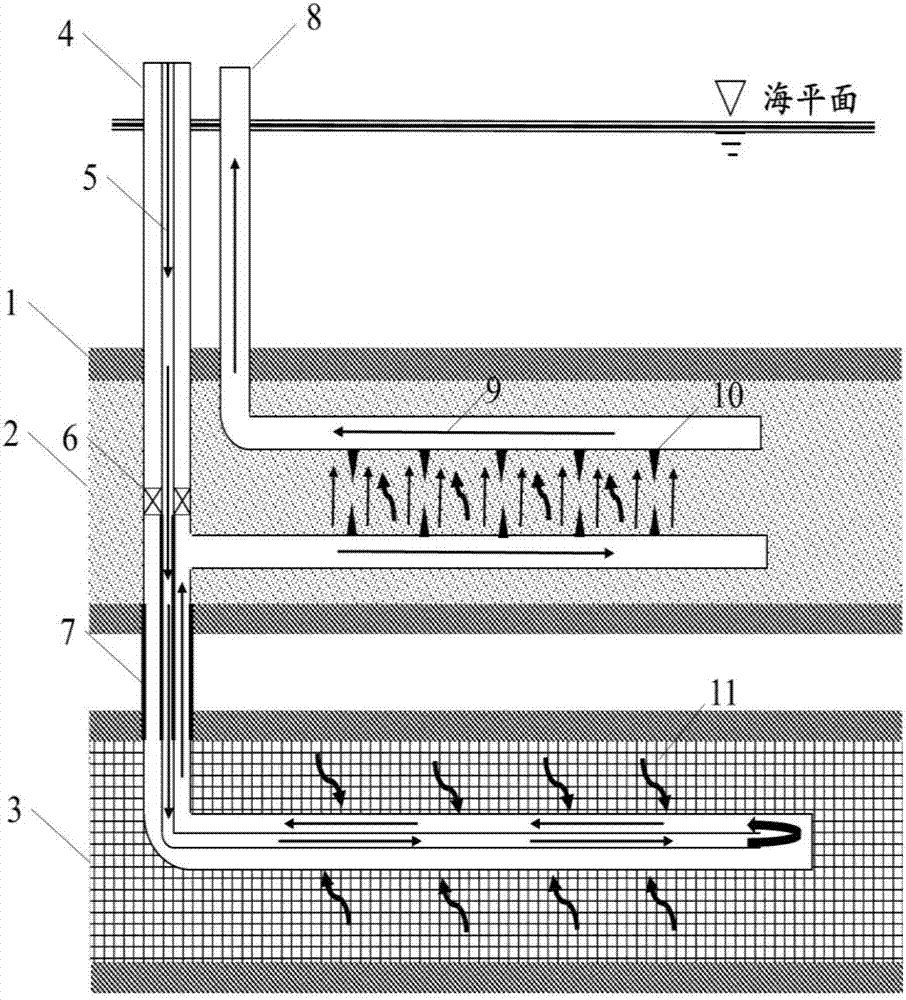

[0018] (1) if figure 1 As shown, according to the geological data of the hydrate reservoir 2, the area with cap rock 1 at the top and geothermal layer 3 at the bottom is selected for construction work, and the temperature of geothermal layer 3 is 120°C;

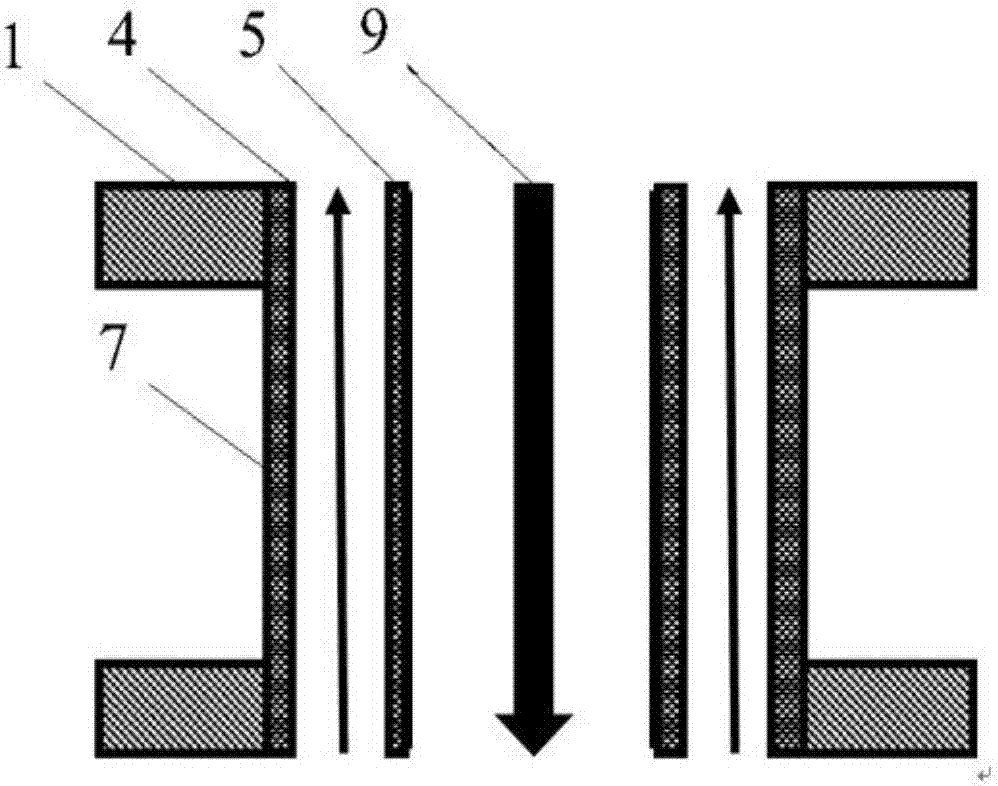

[0019] (2) if figure 1 As shown, a well group system consisting of a dual branch injection well and a horizontal production well 8 is drilled in the construction area, where the dual branch injection well includes a vertical wellbore extending from sea level to the geothermal layer 3, located at The first branch wellbore with a length of 700m at the position and the geothermal layer 3 distance from the top The second branch wellbore with a length of 700m at the position, the horizontal production well 8 is located at the top of the hydrate reser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com