Bridge-stacking secondary stacking device for radioactive waste goods packages

A technology for radioactive waste and cargo packages, which is applied in the field of cargo stacking, can solve the problems of insufficient stacking height of cranes and stackers, swaying of steel cables, and low space utilization rate, etc., so as to improve space utilization rate and positioning accuracy. , Make up for the effect of low space utilization and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific implementations described in this specification are only for explaining the present invention, not for limiting the present invention.

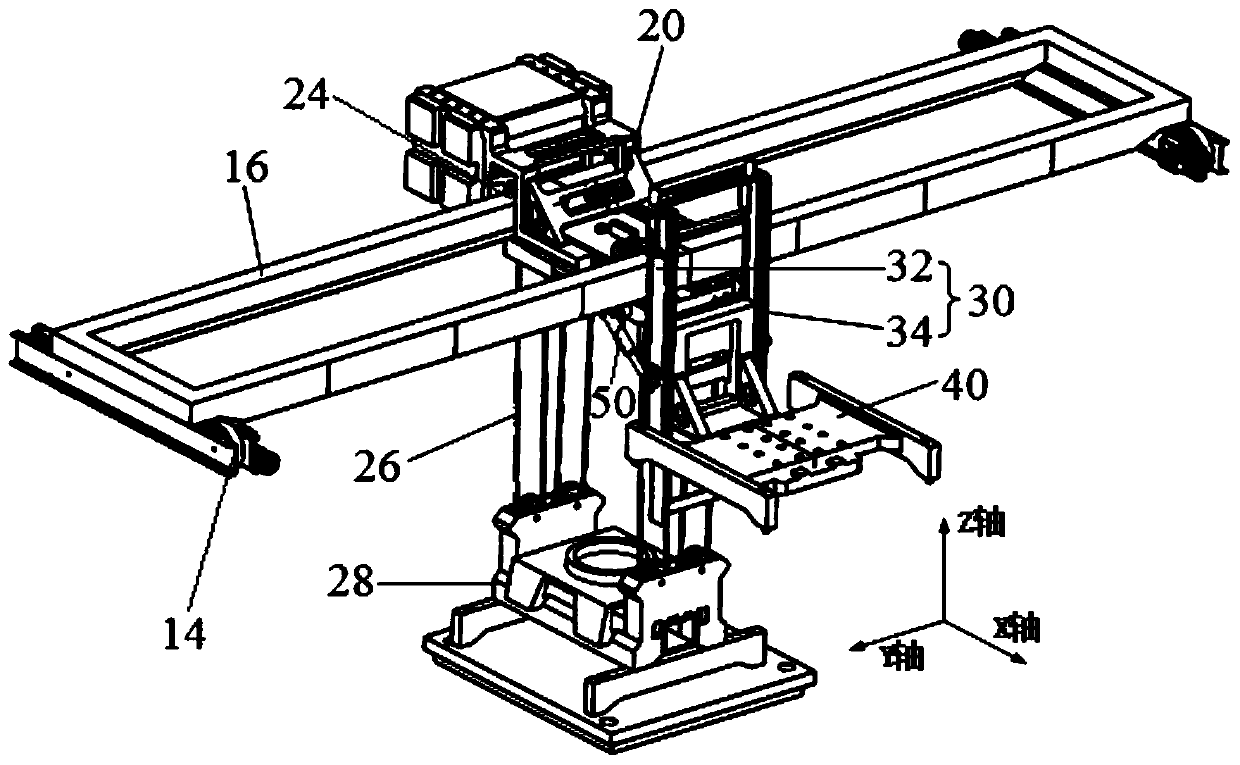

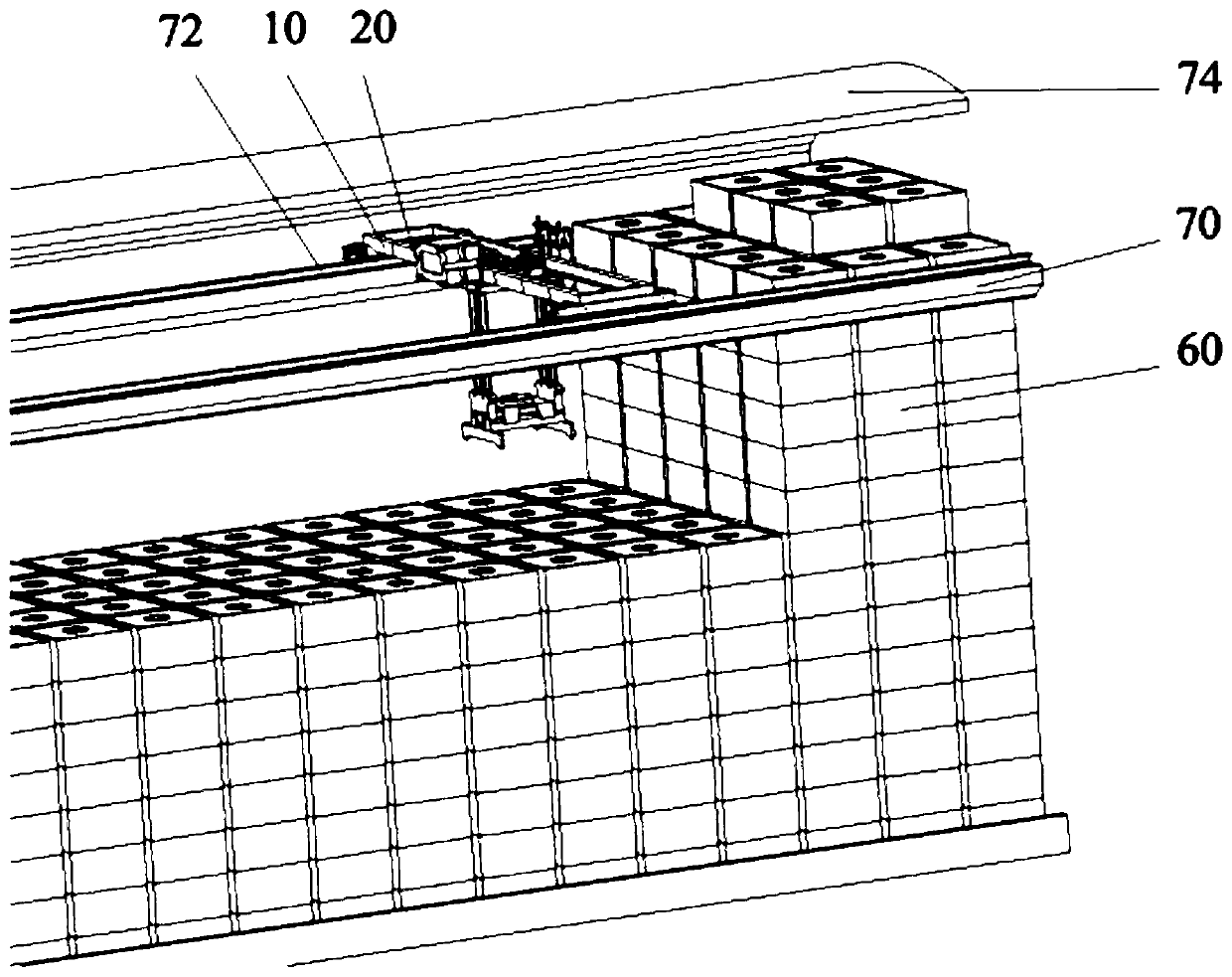

[0024] see figure 1 and figure 2 , the secondary stacking device for bridge-type stacking of radioactive waste bags of the present invention includes a cart 10, a trolley 20, a primary lifting mechanism and a secondary stacking mechanism; For stacking, the secondary stacking mechanism performs secondary lifting and stacking at a higher height for the radioactive waste packages that have been stacked by the primary lifting mechanism to complete the secondary stacking.

[0025] The cart 10 comprises a cart frame, a cart wheel 14 positioned at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com