Assembly type concrete frame structure beam column rigidity connection node

A rigid connection and frame structure technology, applied in building construction, construction, etc., can solve the problems of restricting the use of precast concrete components, complex node connection forms, and high construction technical requirements, and achieves simplification of construction procedures, simplification of complexity, and improvement of construction. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

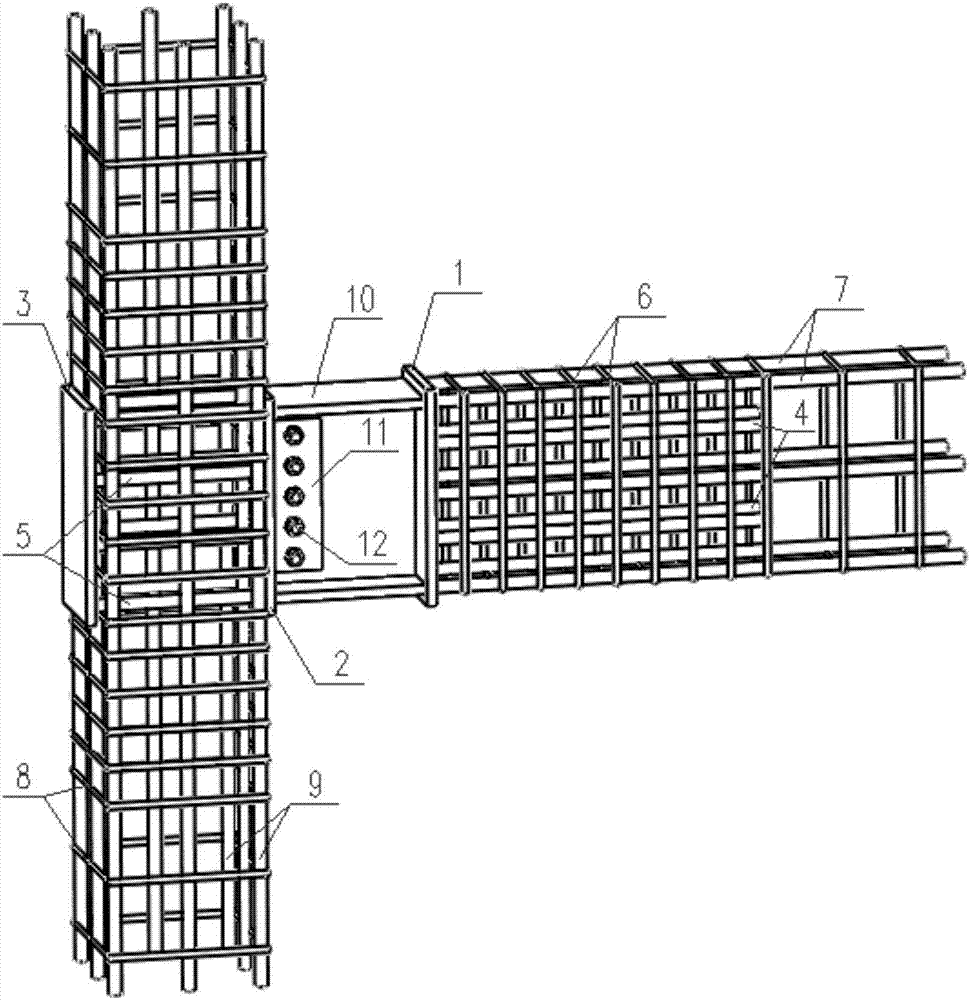

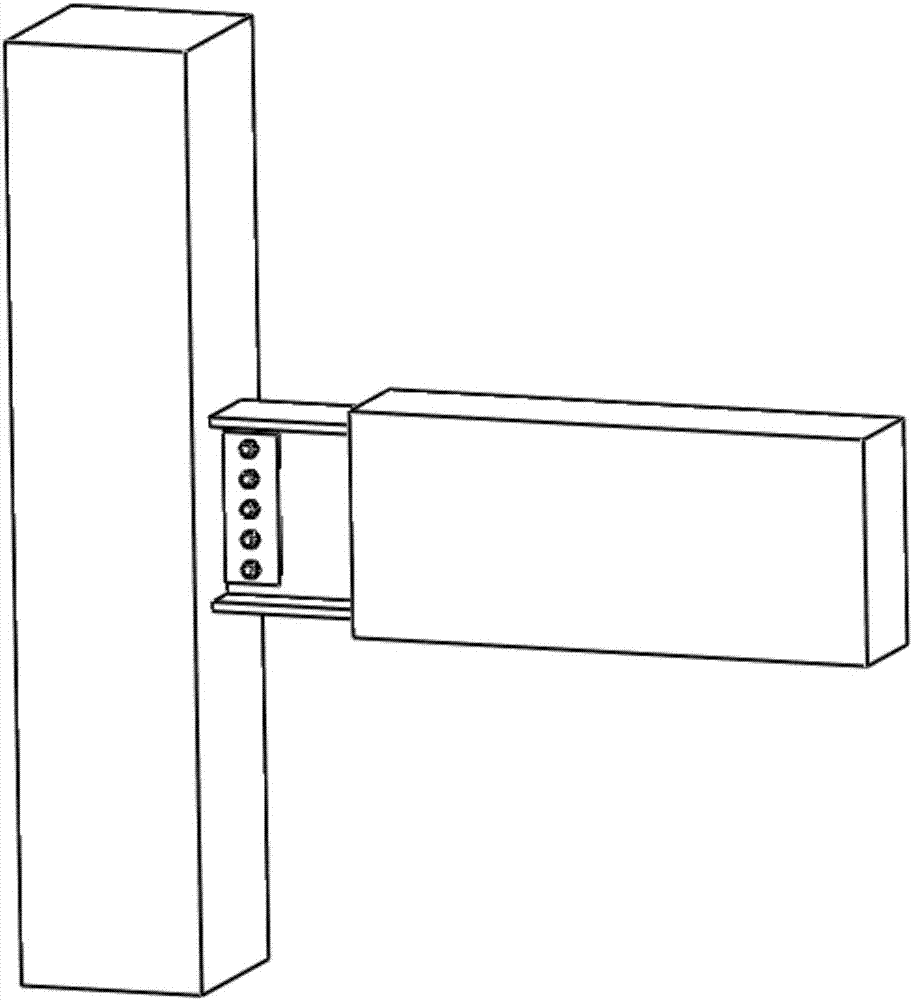

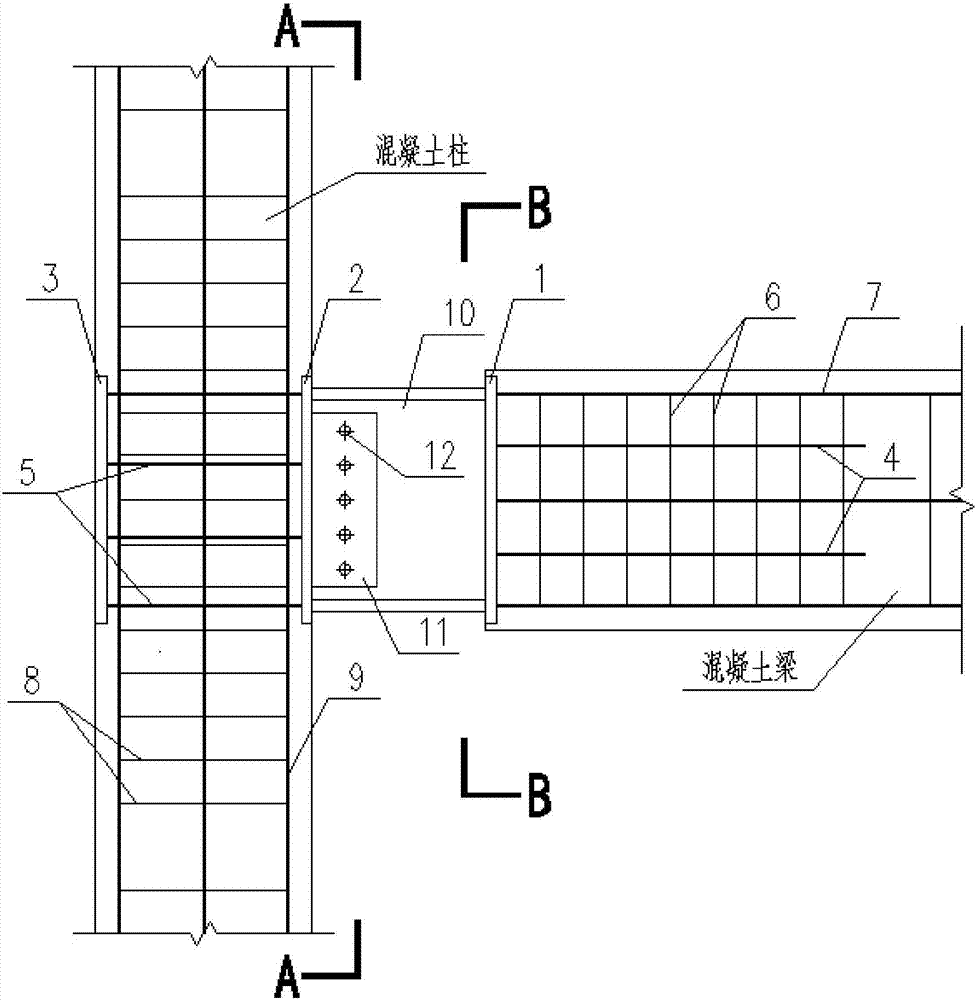

[0045] The following uses the prefabricated concrete frame structure beam-column connection node as an example to illustrate the use process. The cross-section of the frame beam in the prefabricated concrete frame structure is 300×600, and the cross-section of the frame column is 500×500. The reinforcement in the tension area of the frame beam is 2 Ф25 steel bars, the compression area is 2 Ф20 steel bars, the stirrups are Ф8@100, double-leg hoops. There are 2 Ф25 and 1 Ф20 on one side of the frame column, 2 Ф22 and 1 Ф18 on the other side, the stirrup is Ф8@100, and the double leg hoop. The length of the first steel plate of the beam end embedded part is 570mm, the width is 270mm, and the thickness is 25mm. There are 4 internal threaded steel bars in the first embedded part of the embedded part at the beam end, with a diameter of 22mm, 2 rows along the height direction of the beam section, and 2 rows along the width direction of the beam section. The length of the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com