FeCrAl-based alloy for accident-resistant nuclear fuel element and preparation method thereof

A technology for fuel elements and base alloys, which is applied in the field of preparation of FeCrAl-based alloys for accident-resistant nuclear power fuel elements and FeCrAl-based alloys. It can solve the problems that FeCrAl-based alloy materials cannot meet, achieve excellent high-temperature oxidation performance, and prevent hardening and brittleness. Tendency, improve the effect of strong plasticity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

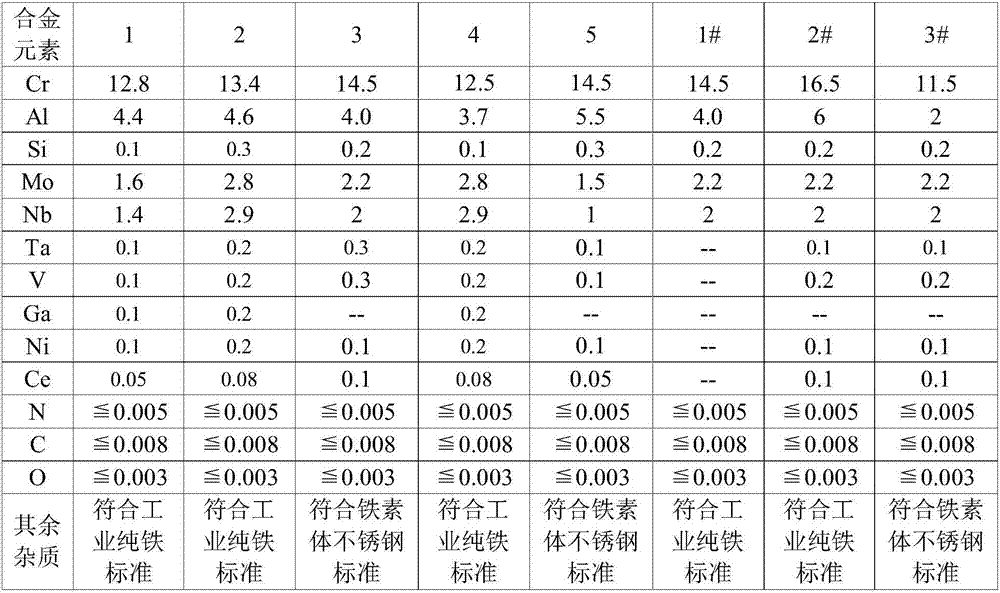

[0035] An accident-resistant FeCrAl-based alloy for nuclear power fuel elements, the specific composition of which is shown in Table 1. In Table 1, 1 to 5 are specific proportions of the present invention, and 1# to 3# are specific proportions of alloys for comparison.

[0036] Among them, 1# is a comparative example without adding metal elements such as Ta and V on the basis of 3, 2# is a comparative example of increasing Cr and Al content on the basis of 3, and 3# is a comparative example of reducing Cr and Al on the basis of 3 content comparison.

[0037] Table 1

[0038]

[0039] Adopt the composition in above-mentioned table 1, adopt following method to prepare alloy, concrete preparation method is:

[0040](1) prepare 20-30 kilograms of ingots with industrial pure iron and high-purity alloys with a purity greater than 99.9% according to the formula in Table 1;

[0041] (2) The above ingot is subjected to a high temperature homogenization annealing temperature. Ann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com