Water-based finish varnish for wood holder pencil and preparation method ofwater-based finish varnish

A varnish, water-based technology, applied in the direction of coating, etc., can solve the problems of coating film performance not meeting consumer requirements, insufficient fullness, insufficient filling, etc., to achieve high smoothness, fast drying, and good adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

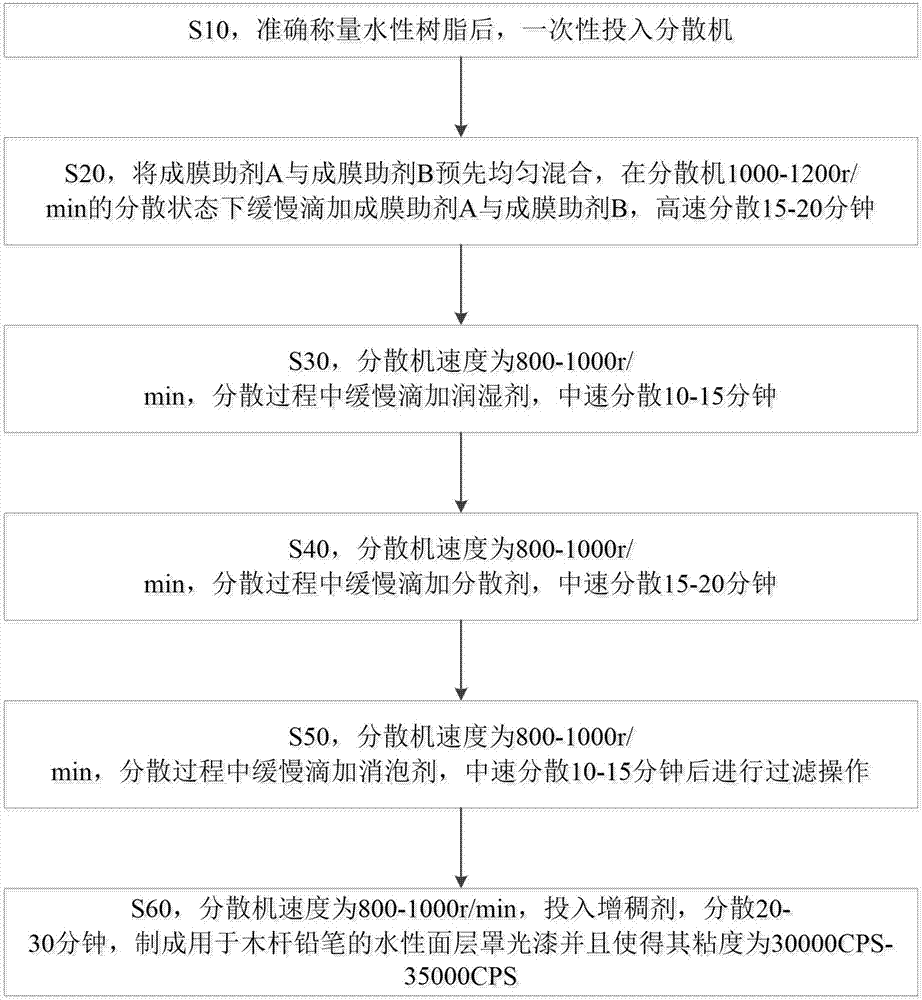

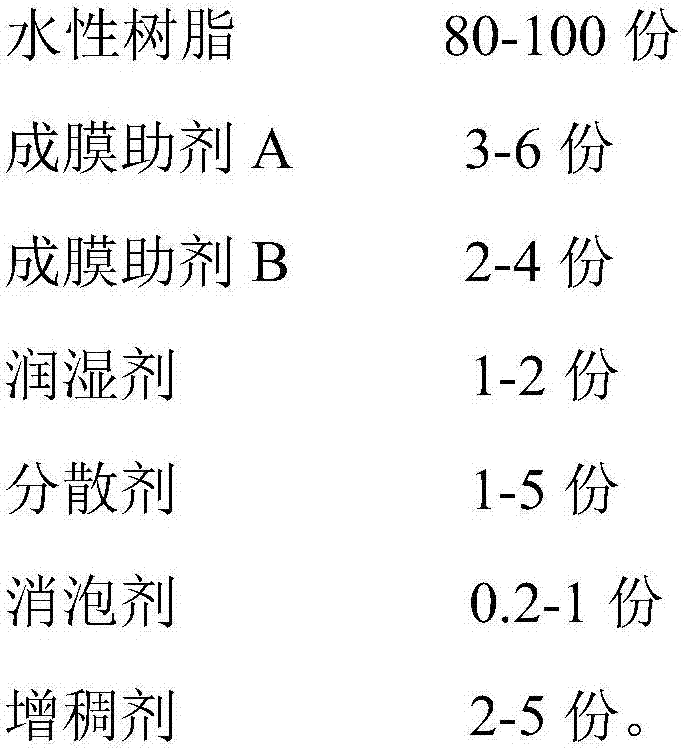

[0028] Such as figure 1 As shown, after accurately weighing 80 parts of water-based resin, put it into the disperser at one time, use deionized water as solvent, and the water-based resin is water-based anionic emulsion resin (Y195); mix 3 parts of film-forming aid A with 4 parts of film-forming aid After B is uniformly mixed, control the disperser to slowly drop film-forming aid A and film-forming aid B under the dispersion state of 1000r / min, and disperse at a high speed for 15 minutes. Film-forming aid A is Dow dipropylene glycol propyl ether (DPNP ), film-forming aid B is Dow dipropylene glycol methyl ether (DPM); control the disperser at 800r / min, slowly add 1 part of wetting agent dropwise, the wetting agent is polyether trisiloxane (8030), disperse 10 minutes; slowly drop 5 parts of dispersant, the dispersant is block copolymer and wet silicone (7117), disperse for 15 minutes; slowly add 0.2 parts of defoamer, disperse for 10 minutes, the defoamer is poly Ether siloxan...

Embodiment 2

[0030] Such as figure 1 As shown, after accurately weighing 85 parts of water-based resin, put it into the disperser at one time, use deionized water as solvent, and the water-based resin is water-based anionic emulsion resin (Y195); mix 6 parts of film-forming aid A with 2 parts of film-forming aid After B is uniformly mixed, control the disperser to slowly drop film-forming aid A and film-forming aid B under the dispersion state of 1200r / min, and disperse at a high speed for 20 minutes. Film-forming aid A is Dow dipropylene glycol propyl ether (DPNP ), film-forming aid B is Dow dipropylene glycol methyl ether (DPM); control the disperser at 1000r / min, slowly add 1.6 parts of wetting agent dropwise, the wetting agent is polyether trisiloxane (8030), disperse 15 minutes; slowly add 3 parts of dispersant, the dispersant is block copolymer and wet silicone (7117), disperse for 10 minutes; slowly add 1 part of defoamer, disperse for 15 minutes, the defoamer is polymer Ether silo...

Embodiment 3

[0032] Such as figure 1 As shown, after accurately weighing 100 parts of water-based resin, put it into the disperser at one time, use deionized water as solvent, and the water-based resin is water-based anionic emulsion resin (Y195); mix 4 parts of film-forming aid A with 2 parts of film-forming aid After B is uniformly mixed, control the disperser to slowly drop film-forming aid A and film-forming aid B under the dispersion state of 1100r / min, and disperse at a high speed for 18 minutes. Film-forming aid A is Dow dipropylene glycol propyl ether (DPNP ), film-forming aid B is Dow dipropylene glycol methyl ether (DPM); control the disperser at 900r / min, slowly add 2 parts of wetting agent dropwise, the wetting agent is polyether trisiloxane (8030), disperse 13 minutes; slowly add 4 parts of dispersant, the dispersant is block copolymer and wet silicone (7117), disperse for 13 minutes; slowly add 0.5 parts of defoamer, disperse for 13 minutes, the defoamer is poly Ether siloxa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com