Method for separating and refining bisnorcholenaldehyde

A refining method and compound technology, which is applied in the field of separation and purification of phytosteraldehydes, can solve the problems of difficult control, environmental pollution, and less amount of silica gel separation and treatment, and achieve easy industrial scale-up, significant economic benefits, and low production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

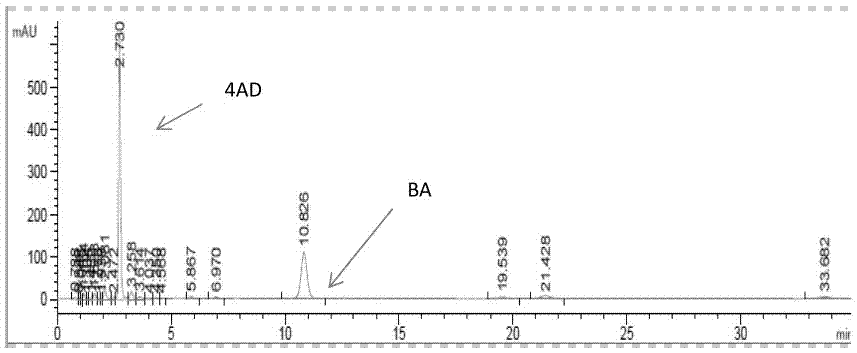

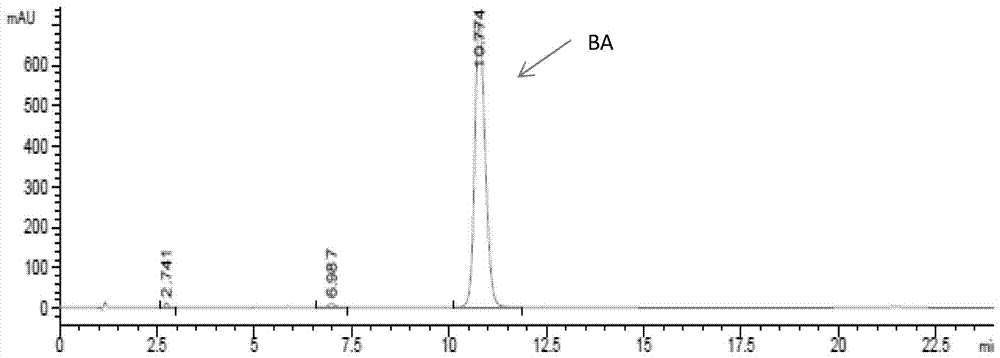

Embodiment 1

[0024] Take 30ml of 50mesh-80mesh HZ-816 macroporous adsorption resin, reserve 4ml of resin, and use the wet method to pack the rest into the resin column. Take 1.5g of concentrated extract, dissolve it completely with a small amount of absolute ethanol (5ml), filter, add the reserved 4ml of resin, and apply the sample by dry method after volatilizing the solvent. Use 14 times of 50% ethanol solution to remove impurities by eluting at a flow rate of 2ml / min, and then use 4 times of 90% ethanol solution to elute at the same flow rate to obtain an eluent containing BA. Concentrate the eluate with a rotary evaporator at 65°C, dissolve it with acetonitrile-methanol-water (16:3:1), filter while hot, and concentrate to crystallize at 0°C. Filter and wash 2-3 times with cold crystallization system. Obtained 0.15g of high-purity pure product, and its content was 98.6% as determined by HPLC.

Embodiment 2

[0026] Take 30ml of 80mesh-120mesh HZ-826 macroporous adsorption resin, reserve 3ml of resin, and pour the rest into the resin column by wet packing. Take 1.5g of concentrated extract, dissolve it completely with a small amount of absolute ethanol (5ml), filter it, add the remaining 3ml of resin, and apply the sample by dry method after evaporating the solvent. Use 13 times of 50% ethanol solution to remove impurities by eluting at a flow rate of 1 ml / min, and then use 4 times of 90% ethanol solution to elute at the same flow rate to obtain an eluent containing BA. Concentrate the eluate with a rotary evaporator at 65°C, dissolve it with acetonitrile-methanol-water (15:3:1), filter while hot, and concentrate to crystallize at 4°C. Filter and wash 2-3 times with cold crystallization system. 0.16 g of high-purity pure product was obtained, and its content was determined to be 98.8% by HPLC.

Embodiment 3

[0028] Take 50ml of 50mesh-80mesh HZ-826 macroporous adsorption resin, and pack it into the column by wet method, and pour the remaining 5ml of resin into the resin column. Take 2.5g of concentrated extract, dissolve it completely with a small amount of absolute ethanol (5ml), filter it, add the remaining 5ml of resin, and apply the sample by dry method after evaporating the solvent. Use 13 times of 50% ethanol solution to remove impurities by eluting at a flow rate of 2ml / min, and then use 4 times of 90% ethanol solution to elute at the same flow rate to obtain an eluent containing BA. Concentrate the eluate with a rotary evaporator at 65°C, dissolve it with acetonitrile-methanol-water (17:3:1), filter while hot, and concentrate to crystallize at -10°C. Filter and wash 2-3 times with cold crystallization system. Obtained 0.18g of high-purity pure product, and its content was 98.5% as determined by HPLC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com