Method for preventing cement bag from leaking ash, and cement bag sealing device

A sealing device and cement bag technology, which is applied in the field of cement packaging, can solve the problems of poor sealing performance of cement packaging bags, no practical effect on leak-proof ash, and increased consumption of sutures, so as to enhance tensile strength, avoid ash leakage, The effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

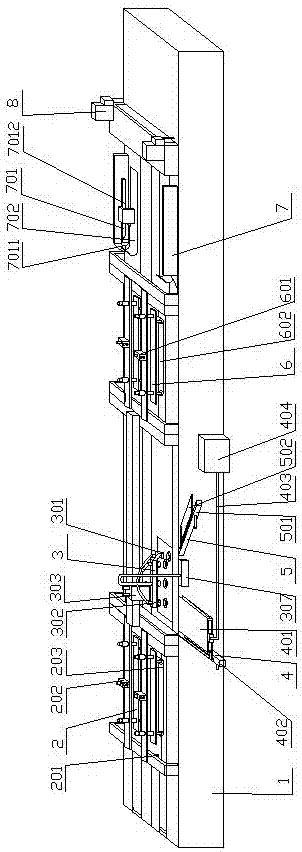

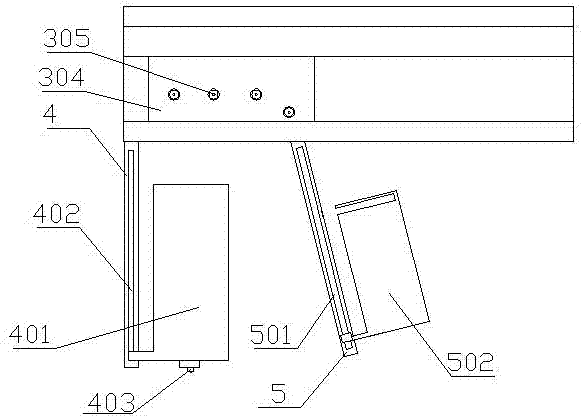

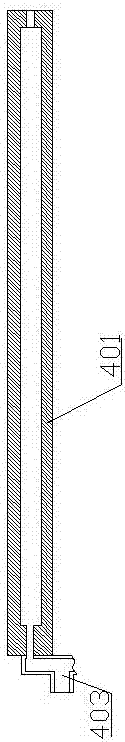

[0019] like Figure 1-5 As shown, the cement bag sealing device of the present invention is an improvement and optimization made on the existing sealing device, and it is to solve the problem of ash leakage caused by improper sealing in the prior art, specifically including the existing The machine base 1 and the filling opening forming mechanism 5 and the bag pressing mechanism 6 which are sequentially fixed on the machine base 1 along the conveying direction of the conveyor belt, as well as the special dust-retaining liner positioning mechanism 4, the crimping mechanism 7, and the bag sewing mechanism 8, Wherein the ash retaining liner positioning mechanism 4 is fixed before the filling mouth forming mechanism 5 , and the crimping mechanism 7 is fixed between the bag pressing mechanism 6 and the bag sewing mechanism 8 . In actual production, an opening mechanism 3 and a bag blocking mechanism 2 need to be installed before the ash retaining liner positioning mechanism 4 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com