A distributed electronic hydraulic braking system

A hydraulic braking and distributed technology, applied in the direction of brakes, brake transmissions, vehicle components, etc., can solve the problems of insufficient active pressure build-up, complex structure of the braking system, and inaccurate pressure adjustment, etc., to achieve full pedal force Decoupling, low failure probability, and improved braking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

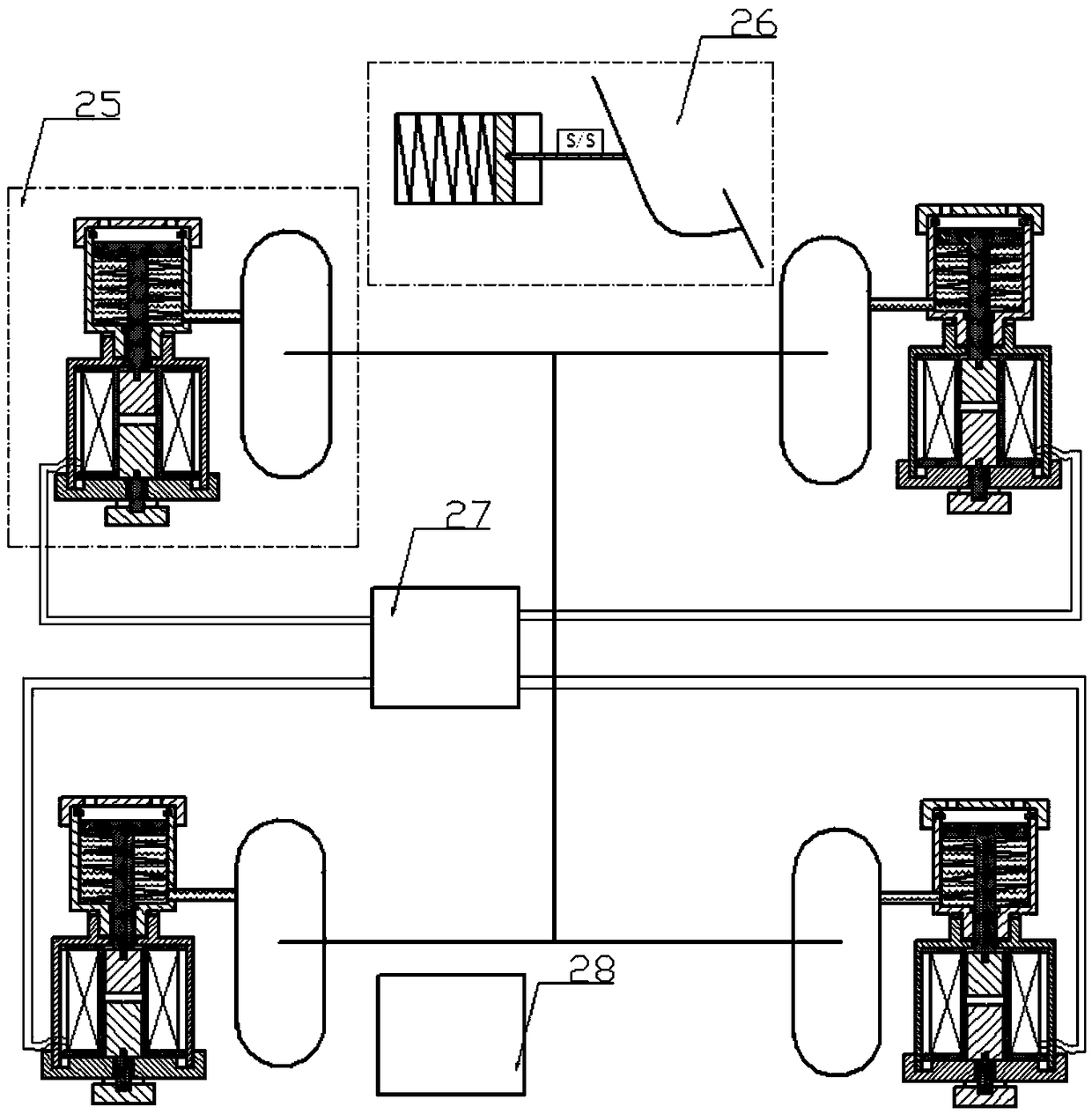

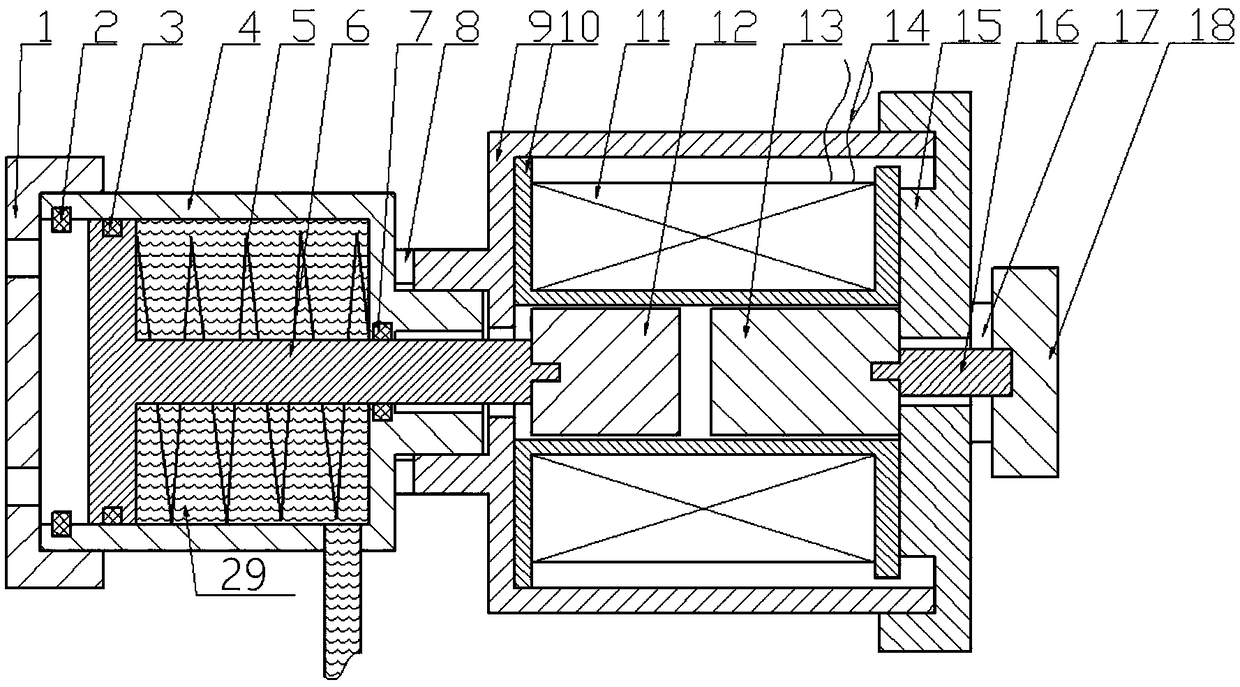

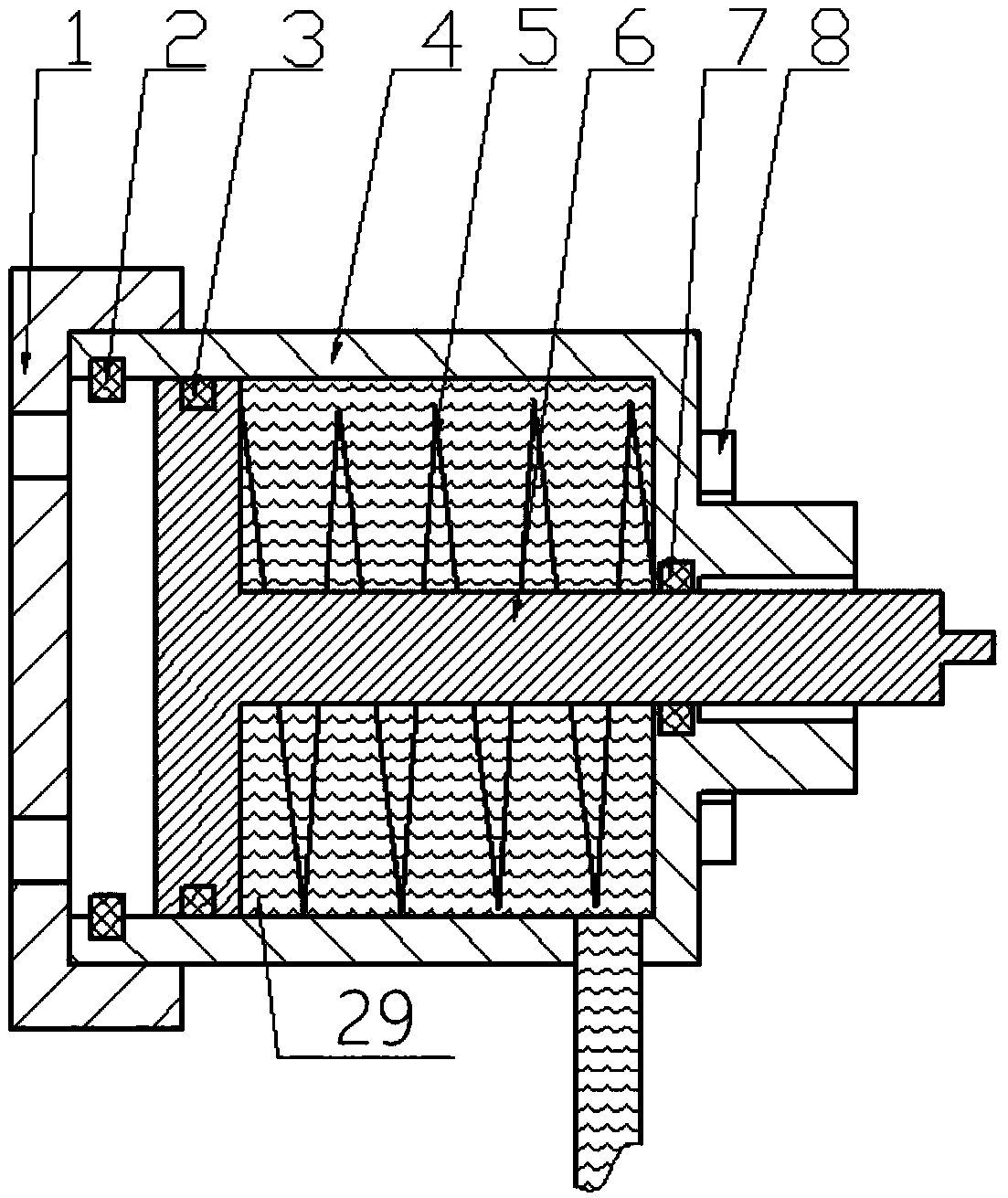

[0038] refer to figure 1 A distributed electronic hydraulic braking system according to the present invention is composed of four wheel brake actuators 25, a driver's pedal feeling simulation mechanism 26, an electronic control unit 27 and a spare small battery 28. The respective hydraulic cylinder blocks 4 of the four wheel brake actuators 25 communicate with the brake wheel cylinders of the corresponding automobile wheels through brake hoses, and the respective electromagnetic parts of the four wheel brake actuators 25 communicate with the electronic control unit The current output terminal of 27 is connected, the power supply input terminal of the electronic control unit 27 is connected with the automobile power supply output terminal, the standby power supply input terminal of the electronic control unit 27 is connected with the spare small battery 28, and the driver's pedal feeling simulation mechanism 26 is used for measuring The displacement sensor 24 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com