Control Method of Residuals in Machining Process of Cavity with Annular Gap

A technology of annular gap and processing process, which is applied in the field of excess material control in the processing of the pintle injector shell of the thrust chamber of the liquid rocket engine, can solve problems such as difficult to remove and clean, launch mission failure, and easy entry of chips, etc., to achieve The cleanliness of the inner cavity of the product is satisfactory, it is convenient to fill and clean, and the effect of breaking the seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0029] The specific embodiment of the present invention comprises the following steps:

[0030] (1) Put the clean solid lard in a drying box with a temperature of 50-60°C and melt it into a liquid state; then use a 400-mesh filter to filter the lard to ensure that there is no excess in the lard;

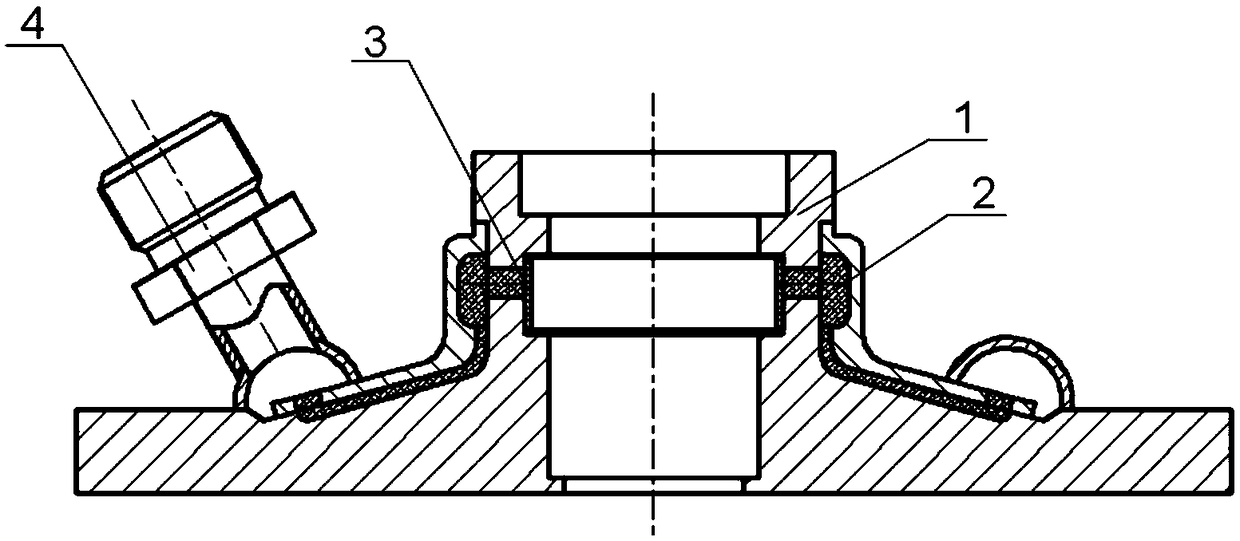

[0031] (2) block the nozzle 4 with a protective piece, put the product 1 upside down in an iron basin container filled with lard, so that the lard can be immersed in the bottom part of the annular gap cavity;

[0032] (3) Place the container and the product together in the refrigerator for 4 hours to freeze the lard completely into a solid state and ensure that the lard is completely filled in the annular gap; clean up;

[0033] (4) According to the width of the annular groove of the product 3.5mm and the diameter of 31mm, considering the overlap after bending, the length of the required spring steel sheet is calculated to be 100mm, and then the spring steel sheet is pre-bent into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap