Rubber frame, backlight module, display device and detaching jig

A backlight module and plastic frame technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of fragile LCD panels and scrapped backlight modules, achieve fast and easy disassembly, reduce material scrapping rate, The effect of reducing maintenance or rework time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, and not to limit the present invention.

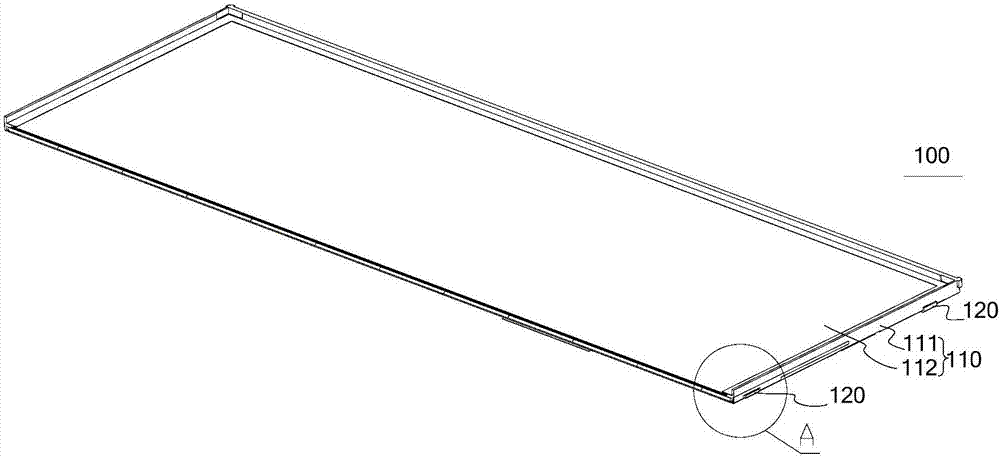

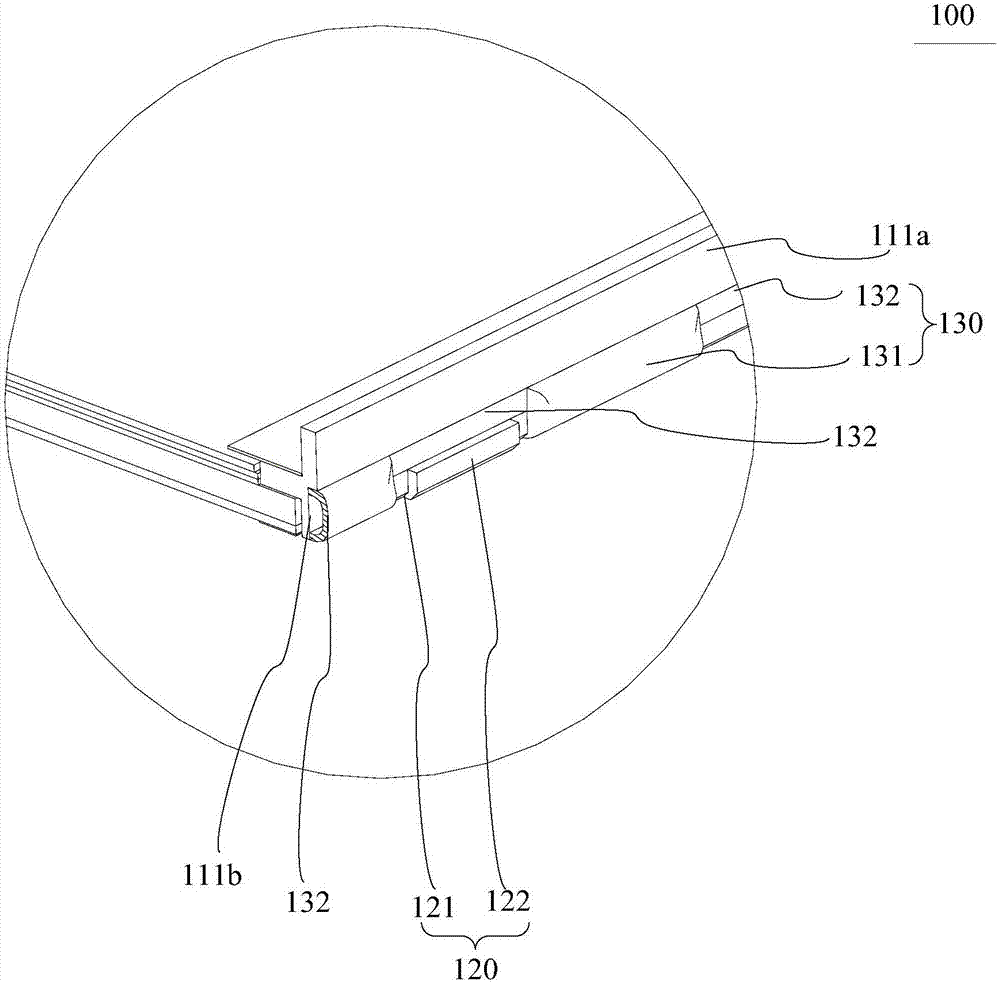

[0050] reference figure 1 , figure 2 , image 3 with Figure 4 , The first aspect of the present invention relates to a plastic frame 100 used for a backlight module 200. Wherein, the plastic frame 100 includes a plastic frame body 110 which includes a plurality of first side walls 111 connected in sequence, and the plurality of first side walls 111 collectively enclose a receiving space 112. One side of the accommodating space forms the first bonding surface 111 a, that is, the first bonding surface 111 a is the outer side wall of the first side wall 111.

[0051] The plastic frame 100 further includes a detachment assembly 130, and the detachment assembly 130 includes at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com