Method for measuring content of nitrite in edible salt

A technology of nitrite and determination method, which is applied in the field of determination of nitrite content in table salt, can solve the problems of needing large instruments, interference, and high analysis cost, and achieve high recovery accuracy, improved result accuracy, and precise detection high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

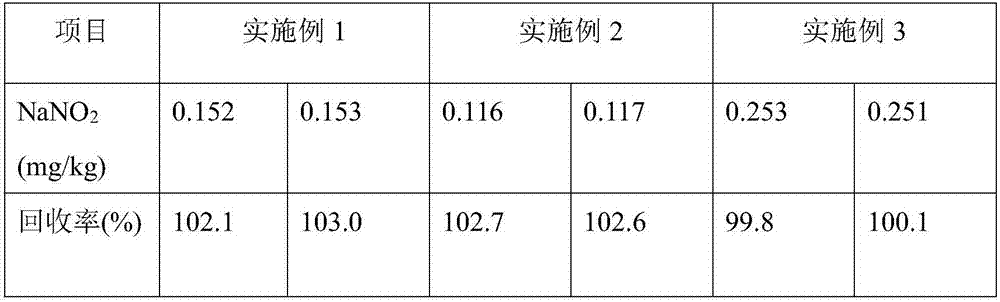

Embodiment 1

[0021] Dispose of salt solution as follows:

[0022] (1) Preparation of salt sample solution: pipette 10 g of salt sample, dissolve it in 100 mL of deionized water, and prepare a salt solution with a concentration of 0.1 g / mL;

[0023] (2) Flow the above salt solution through Chelex-100 resin at a flow rate of 1.2mL / min, the particle size of the resin is 100-200 mesh, the diameter of the resin layer is 3mm, the height of the resin layer is 6cm, and the filtrate I is collected;

[0024] (3) Flow the filtrate I through a 732-type cation exchange resin at a flow rate of 1.5 mL / min, the resin particle size is 100-150 mesh, the diameter of the resin layer is 4 mm, and the height of the resin layer is 7 cm to collect the filtrate II;

[0025] (4) Flow the filtrate II through maleic rosin glyceryl acrylate macroporous adsorption resin at a flow rate of 2.0mL / min, the particle size of the resin is 60-100 mesh, the diameter of the resin layer is 5mm, and the height of the resin layer i...

Embodiment 2

[0035] Dispose of salt solution as follows:

[0036] (1) Prepare salt sample solution: pipette 20g salt sample, dissolve it with 200mL deionized water, and prepare a salt solution with a concentration of 0.1g / mL;

[0037] (2) Flow the above salt solution through Chelex-100 resin at a flow rate of 1.2mL / min, the particle size of the resin is 100-200 mesh, the diameter of the resin layer is 6mm, the height of the resin layer is 8cm, and the filtrate I is collected;

[0038] (3) Flow the filtrate I through a 732-type cation exchange resin at a flow rate of 1.5 mL / min, the resin particle size is 100-150 mesh, the diameter of the resin layer is 7 mm, and the height of the resin layer is 9 cm to collect the filtrate II;

[0039] (4) Flow the filtrate II through maleic rosin glyceryl acrylate macroporous adsorption resin at a flow rate of 2.0mL / min, the particle size of the resin is 60-100 mesh, the diameter of the resin layer is 8mm, and the height of the resin layer is 10cm to coll...

Embodiment 3

[0042] Dispose of salt solution as follows:

[0043] (1) Prepare salt sample solution: pipette 15g salt sample, dissolve it with 150mL deionized water, and prepare a salt solution with a concentration of 0.1g / mL;

[0044] (2) Flow the above salt solution through Chelex-100 resin at a flow rate of 1.2mL / min, the particle size of the resin is 100-200 mesh, the diameter of the resin layer is 5mm, the height of the resin layer is 7cm, and the filtrate I is collected;

[0045] (3) Flow the filtrate I through the 732-type cation exchange resin at a flow rate of 1.5 mL / min, the resin particle size is 100-150 mesh, the diameter of the resin layer is 6 mm, and the height of the resin layer is 8 cm to collect the filtrate II;

[0046] (4) Flow the filtrate II through maleic rosin glyceryl acrylate macroporous adsorption resin at a flow rate of 2.0mL / min, the particle size of the resin is 60-100 mesh, the diameter of the resin layer is 6mm, and the height of the resin layer is 8cm to col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com