Middle storage type medium-speed milling positive pressure direct blowing type powder making system

A pulverizing system, direct blowing technology, applied in the direction of block/powder fuel preparation, block/powder supply/distribution, combustion method, etc. Small boilers are difficult to operate safely, economically, and stably, and it is difficult to achieve uniform distribution of pulverized coal particles, so as to achieve the effect of broadening the demand for combustion stability, widening the maintenance space, and convenient transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

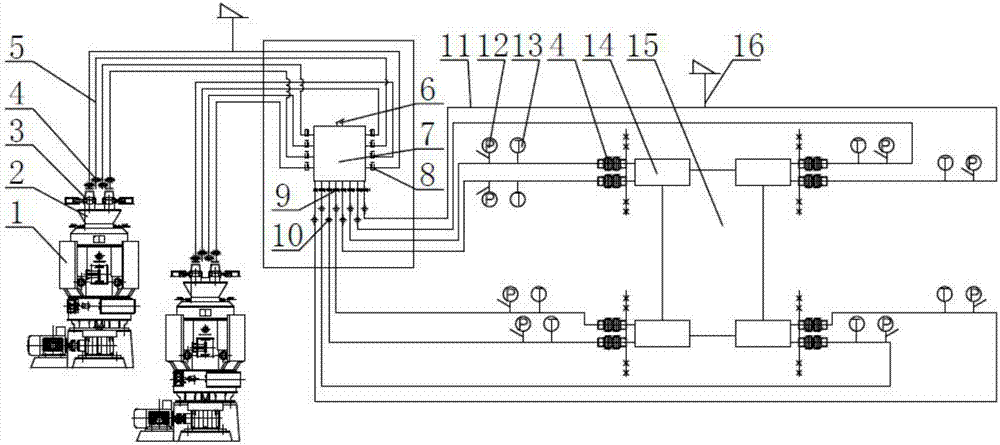

[0033] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0034] see Figure 1 to Figure 6 , an intermediate storage bin type medium speed mill positive pressure direct blowing type pulverization system, including several coal mills 1 arranged in sequence, a dynamic separator 2 arranged at the outlet of the coal mill, and several coal mills arranged at the outlet of the dynamic separator 2 The first pulverized coal pipe 5 arranged side by side, the air-powder mixing balance chamber 7 corresponding to the outlet of the first pulverized coal pipe 5 connected to every two coal mills 1, and the several air-powder mixing balance chambers 7 correspondingly conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com