Diesel engine fuel oil injection micro electric control unit combined pump

A diesel engine and fuel injection technology, which is applied in fuel injection pumps, engine control, fuel injection control, etc., can solve the problems of complex single pump structure, large shape that cannot be installed, and poor uniformity control, so as to improve the consistency of fuel volume The effects of stability and uniformity, precise fuel injection timing, and strong idling loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

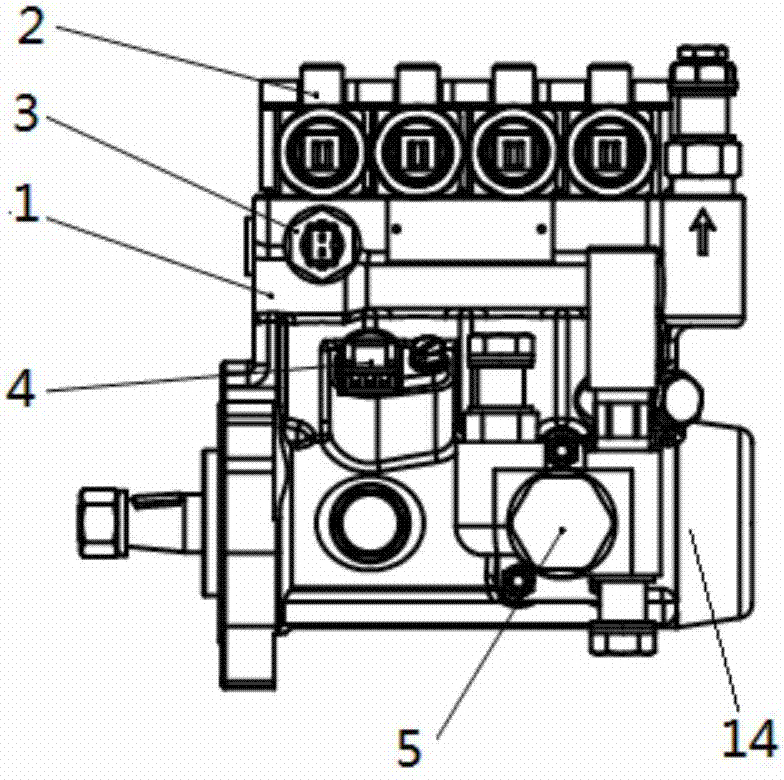

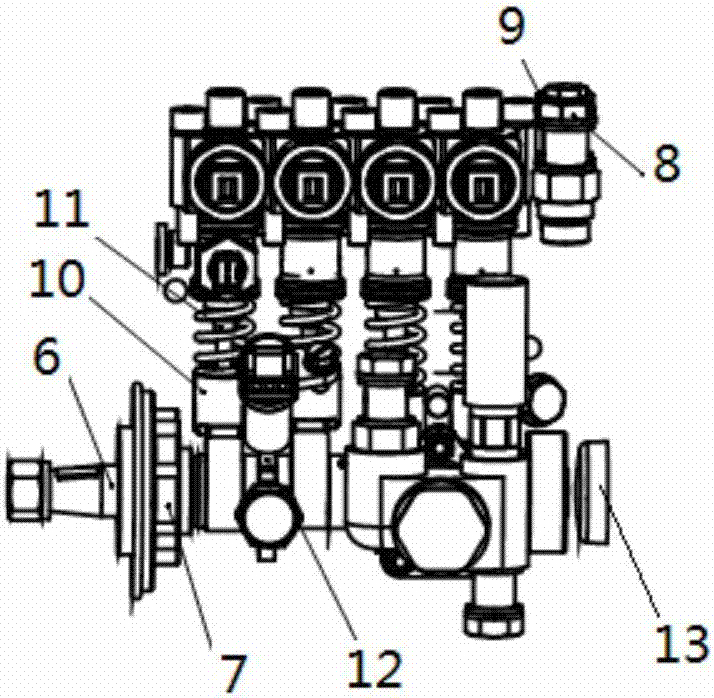

[0031] figure 1 , figure 2 with image 3 See shown. The four-cylinder diesel engine fuel injection electronic control unit combination pump shown in the figure includes a pump body 1, and the pump body 1 is connected to the engine (not shown in the figure) by means of a mechanical connection such as a flange or a bracket.

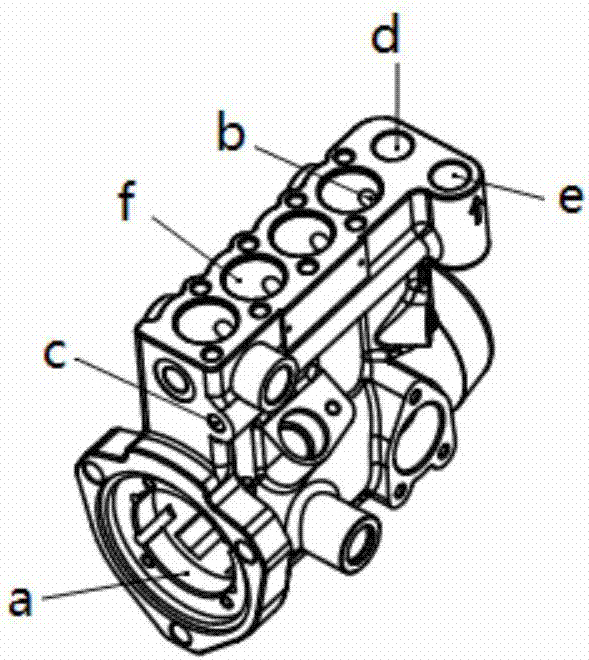

[0032] The pump body 1 of the diesel engine fuel injection electronic control unit combination pump is provided with a camshaft installation chamber a below and four cylinder chambers f above, and the distance between the cylinder centers between adjacent cylinder chambers is ≤33mm. Height≤160mm. The bottom of the four cylinder chambers f communicates with the camshaft installation chamber a. An oil passage d and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com