Rupture disk perforating casing coupling device

A casing coupling and rupture disk technology, applied in the field of oil and gas field development tools, can solve the problems of large influence of oil and gas layers, complex construction procedures, high construction costs and risks, saving tripping time, shortening operation cycle, increasing The effect of job difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The structural principle of the present invention will be discussed in detail below in conjunction with the accompanying drawings.

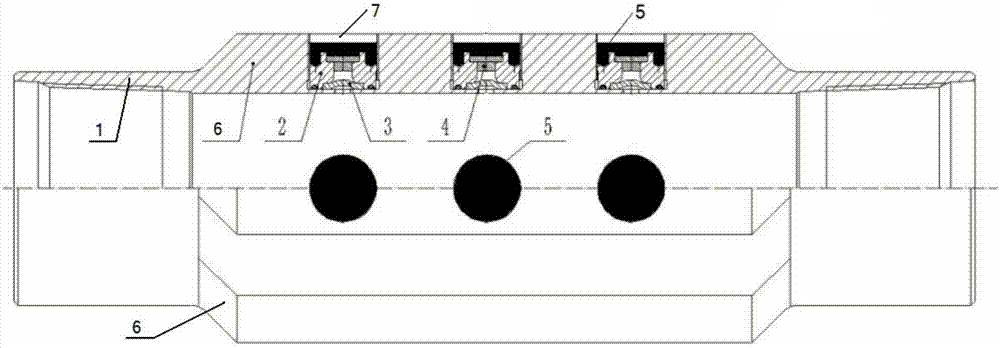

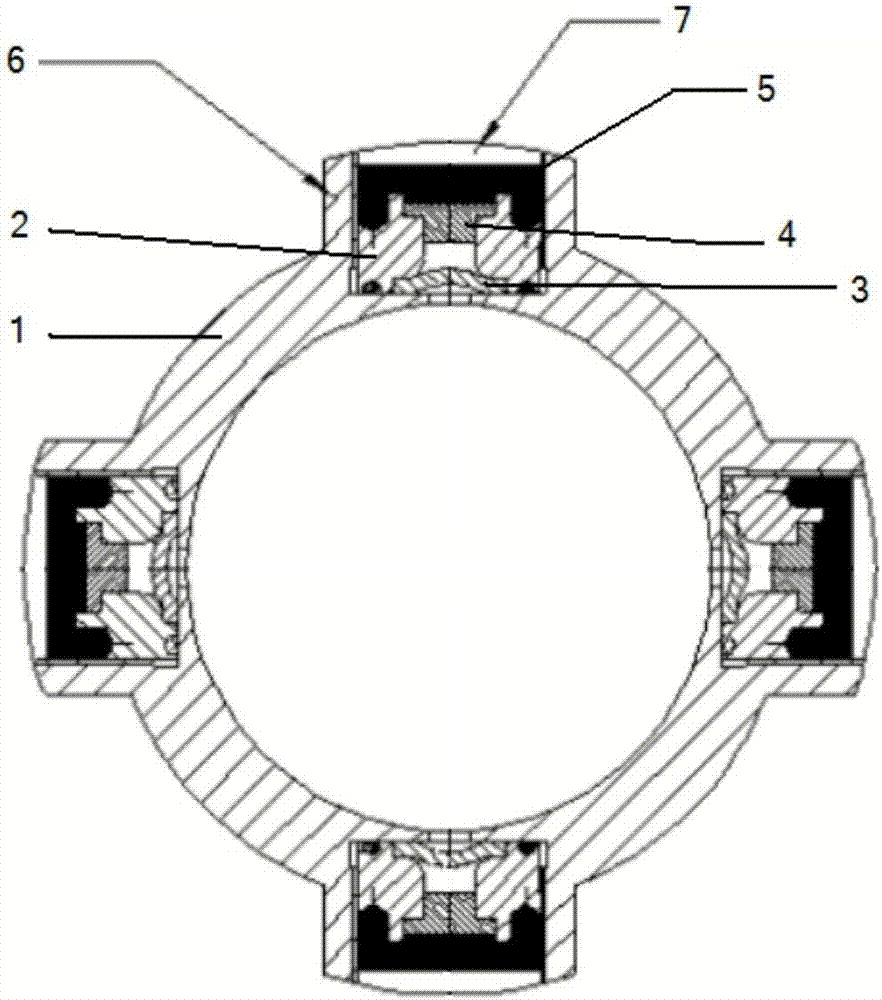

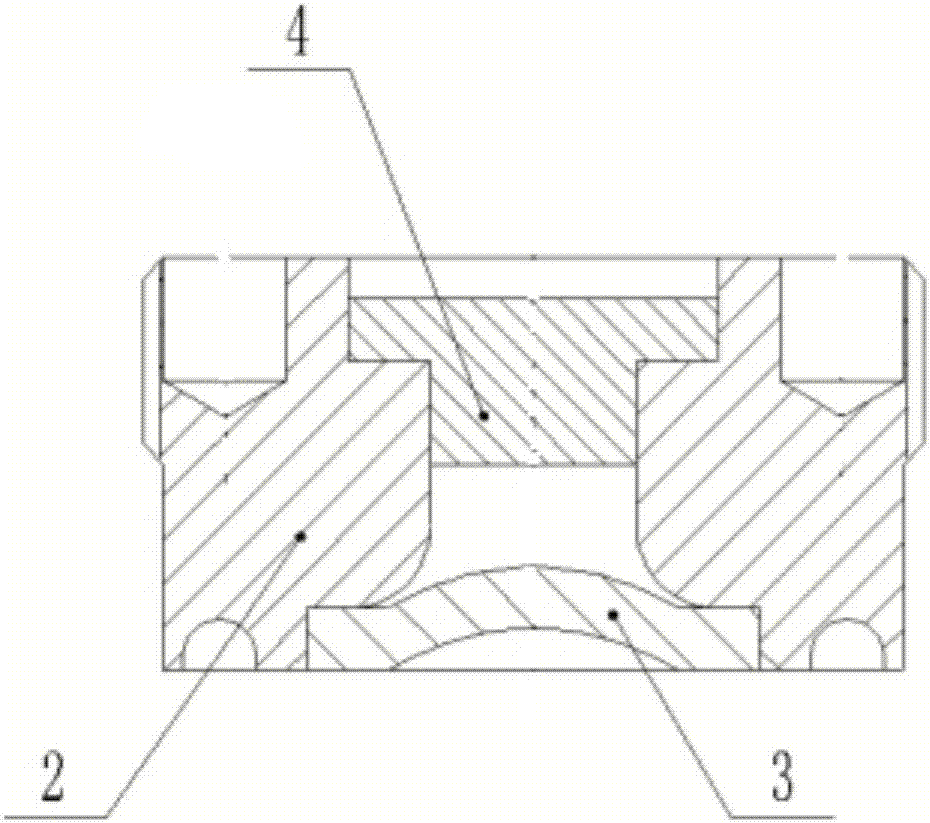

[0017] Such as figure 1 , figure 2 As shown, a rupture disk perforating casing coupling device includes a coupling body 1, on which a protrusion 6 extending in the axial direction is arranged at intervals of 90° in the circumferential direction, and each protrusion There are three openings 7 along the radial direction on the lifter 6, and a nut 2 is arranged inside each opening 7, and a rupture disc 3 is installed between one end of the nut 2 and the bottom surface of the opening 7, and the other end of the nut 2 is installed A pressure cap 4 is provided, and the pressure cap 4 together with the nut 2 and the rupture disc 3 forms a cavity with standard atmospheric pressure (see image 3 ), the upper end of the pressure cap 4 is coated with a self-dissolving softening film 5.

[0018] Working principle of the present invention:

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com