Welding process of plug-in unit of PCB (Printed Circuit Board)

A technology of PCB board and welding process, which is applied in the field of PCB board plug-in welding process, can solve problems such as low safety, increase the probability of bad solder joints, and affect cutting, so as to strengthen employee safety protection, facilitate board insertion operations, Effect of reducing solder loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

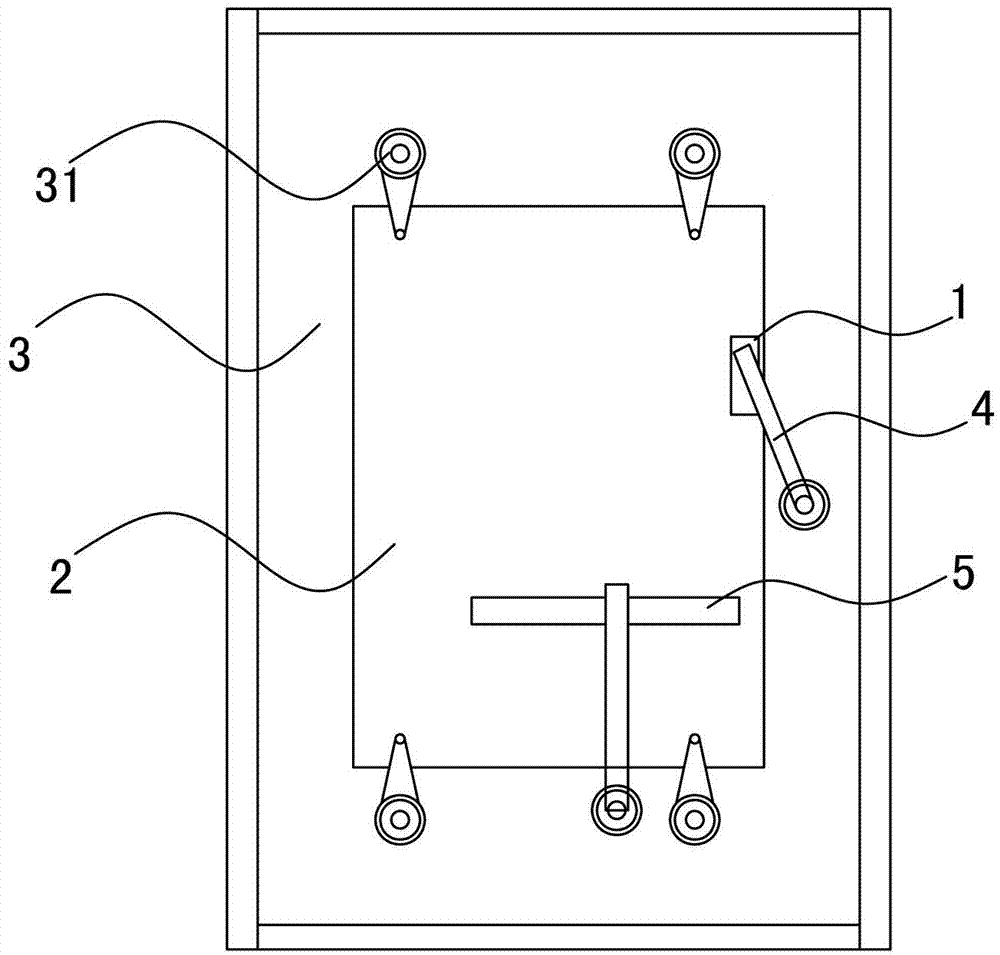

[0031] refer to figure 1 , a kind of PCB board plug-in welding process of the present invention, described process comprises the steps:

[0032] (1) Cutting the feet of components, using an automatic cutting machine to trim the feet of components to uniform and standardized specifications, and obtain short-leg components of uniform specifications 1;

[0033] (2), plug-in, first put the PCB board 2 to be processed into the limit groove of the wave soldering machine tray 3, and then fix the PCB board 2 on the tray 3 with the four fixing buckles 31 on the tray 3, and then put the upper The components 1 processed in one step are respectively inserted into the corresponding pads of the PCB board 2 mounted on the tray 3 of the wave soldering machine;

[0034] (3), check and press the parts, visually confirm that each component 1 is inserted correctly, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com