A kind of preparation method of ultra-thin through-hole anodic aluminum oxide film

An anodic aluminum and anodic oxidation technology, which is applied in vacuum evaporation plating, coating, sputtering plating and other directions, can solve the problems of difficult to precisely control the thickness of nanopores, complicated steps, etc., and achieves easy mass production and simple control. , the method is easy to repeat the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

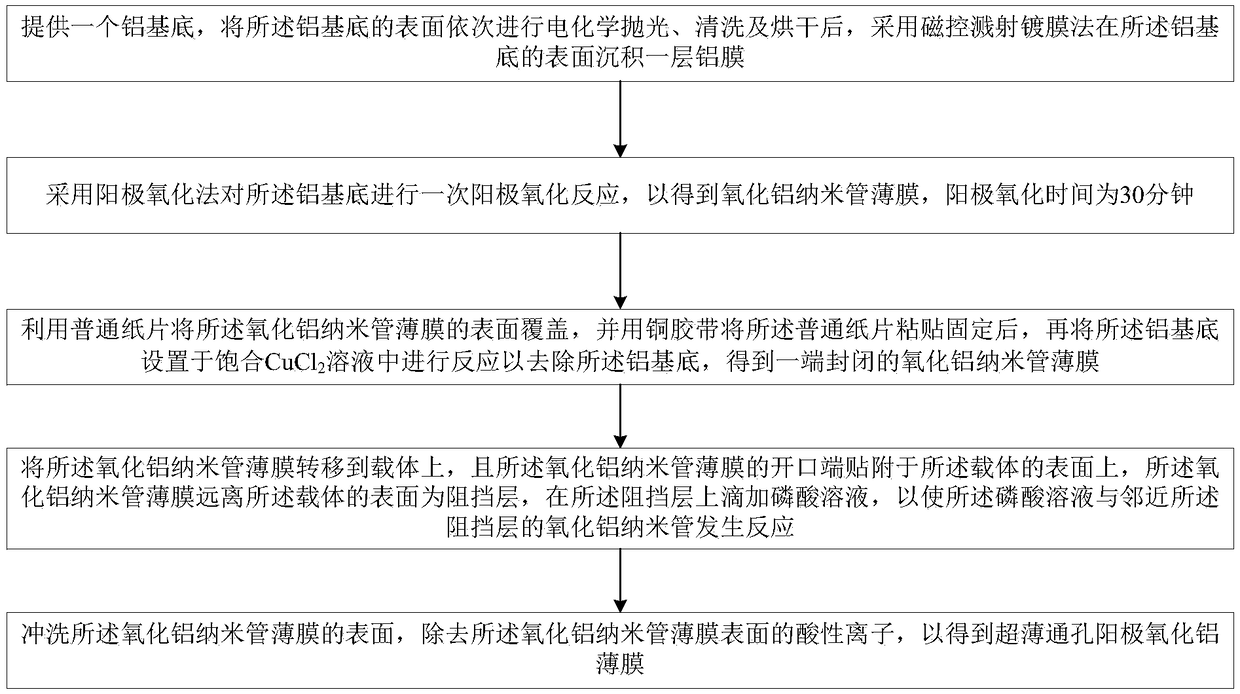

[0031] The preparation method of the ultra-thin through-hole anodic aluminum oxide film mainly includes the following steps:

[0032] In step 1, an aluminum substrate is provided, and after the surface of the aluminum substrate is electrochemically polished, cleaned and dried in sequence, an aluminum film is deposited on the surface of the aluminum substrate by magnetron sputtering coating method. In this embodiment, the sputtering time is 347-3472s, the aluminum film thickness is 100-1000nm; the sputtering power is 200W, the sputtering gas mass flow rate is 35sccm, and the sputtering rate is 0.288nm / s.

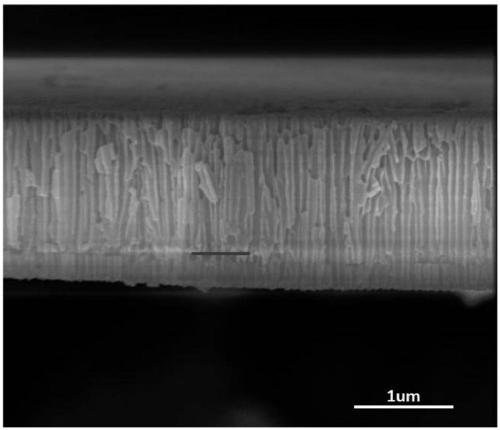

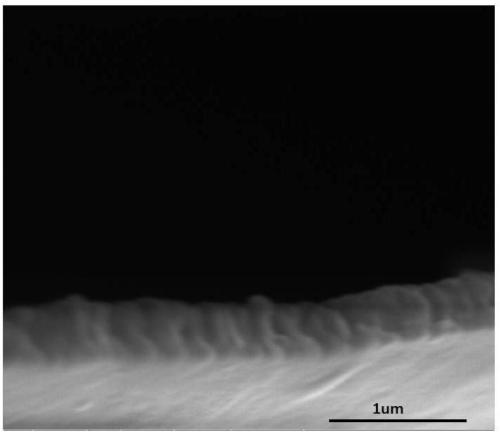

[0033] In step 2, the aluminum substrate is subjected to an anodic oxidation reaction by an anodic oxidation method to obtain an aluminum oxide nanotube film, and the anodic oxidation time is 30 minutes. In this embodiment, the thickness of the obtained alumina nanotubes is 2.696 μm, the diameter of the alumina nanotube film is 1-3 cm, the control voltage is 40-60 V, and the ...

no. 1 approach

[0038] (1) The pure aluminum sheet (purity is 99.99%, size is 2cm×2cm×1mm) is electrochemically polished in a mixture of perchloric acid and ethanol (volume ratio 1:4), and the polishing voltage is 15-18V, The current is 1A, and the polishing time is 3min; the polished aluminum sheet is ultrasonically cleaned with deionized water and dried.

[0039] (2) Utilize the magnetron sputtering coating method to deposit a uniform aluminum film on the surface of the polished aluminum sheet, the sputtering power is 200W, the sputtering gas mass flow rate is 35sccm, and the sputtering rate obtained through regulation is 0.288nm / s, the sputtering time is 694s.

[0040] (3) The coated aluminum sheet is used as an anode, and the graphite sheet is used as a cathode, and an anodic oxidation reaction is carried out in an oxalic acid solution with a mass percentage of 3%. The anodizing temperature is 20°C, the voltage is 40V, the current is 20mA, and the oxidation time is 30min. After the rea...

no. 2 approach

[0044] The second embodiment is basically the same as the first embodiment, except that the sputtering time in step (2) of the second embodiment is 1041s, and a 300nm thick aluminum film is deposited on the surface of the aluminum sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com