Method for preparing biodegradable carboxymethyl starch/polyvinyl alcohol composite film through wet method

A technology of carboxymethyl starch and polyvinyl alcohol is applied in the field of preparation of carboxymethyl starch composite film to achieve the effects of good elasticity, prevention of dissolution shrinkage deformation, and reliable strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

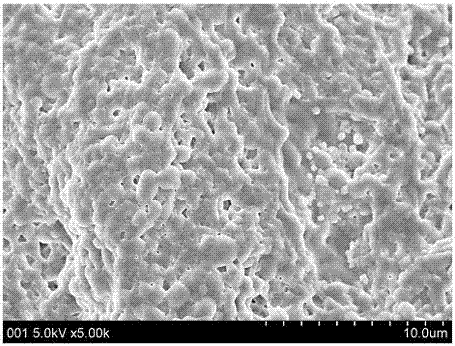

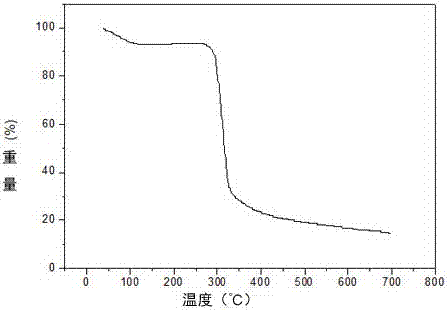

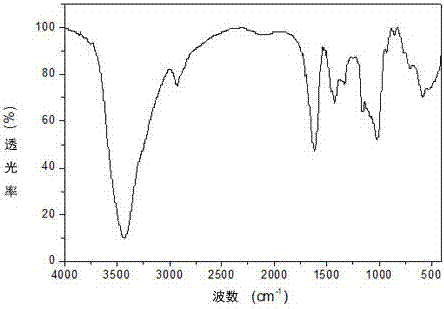

Image

Examples

Embodiment 1

[0030] (1) Carboxymethyl starch was prepared into a homogeneous solution with a mass concentration of 2% with distilled water;

[0031] (2) Prepare polyethylene with distilled water and alcohol to form a homogeneous solution with a mass concentration of 8%;

[0032] (3) Evenly mix 2% carboxymethyl starch solution with 8% polyvinyl alcohol aqueous solution at a mass ratio of 1:5;

[0033] (4) Spread the mixture evenly in the mold of the plexiglass utensils, and make the thickness 0.500-3.500mm. After defoaming, let it stand at room temperature for 16 hours, and then put it in 100mL supersaturated K 2 SO 4 In the solution, use 2ml of 37wt% formaldehyde solution to crosslink for 30min at pH 2.5 and temperature 85°C to obtain a composite film of carboxymethyl starch and polyvinyl alcohol, and rinse the composite film with deionized water until neutral.

[0034]The thickness of the carboxymethyl starch and polyvinyl alcohol composite film is 0.313mm, and the moisture content is 1...

Embodiment 2

[0036] (1) Carboxymethyl starch was prepared into a homogeneous solution with a mass concentration of 3% with distilled water;

[0037] (2) Prepare polyethylene with distilled water and alcohol to form a homogeneous solution with a mass concentration of 5%;

[0038] (3) Evenly mix 3% carboxymethyl starch solution with 5% polyvinyl alcohol aqueous solution at a mass ratio of 1:4;

[0039] (4) Spread the mixture evenly in the mold of the plexiglass utensils, and make the thickness 0.500~2.500mm. After defoaming, let it stand at room temperature for 24 hours, and then add it to 100mL supersaturated KNO 3 In the solution, use 3ml of 40wt% acetaldehyde solution to crosslink for 20min at pH 3 and temperature 75°C to obtain a composite film of carboxymethyl starch and polyvinyl alcohol, and rinse the composite film with deionized water until neutral.

[0040] The thickness of the carboxymethyl starch and polyvinyl alcohol composite film is 0.207mm, the water content is 13.35%, and t...

Embodiment 3

[0042] (1) Carboxymethyl starch was prepared into a homogeneous solution with a mass concentration of 2% with distilled water;

[0043] (2) Prepare polyethylene with distilled water and alcohol to form a homogeneous solution with a mass concentration of 7%;

[0044] (3) Evenly mix 3% carboxymethyl starch solution with 7% polyvinyl alcohol aqueous solution at a mass ratio of 1:8;

[0045] (4) Spread the mixture evenly in the mold of the plexiglass utensils, and make the thickness 0.800-4.100mm. 2 SO 4 In the solution, use 2ml of 30wt% glyoxal solution to crosslink for 40 minutes at pH 2 and temperature 80°C to obtain a composite film of carboxymethyl starch and polyvinyl alcohol, and rinse the composite film with deionized water until neutral.

[0046] The thickness of the carboxymethyl starch and polyvinyl alcohol composite film is 0.427mm, the water content is 24.19%, and the test calculation shows that its breaking strength is 13.387N / mm 2 , the elongation at break is 106...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com