Concrete aggregate used for replacing crushed stone aggregate and related concrete

A technology of concrete aggregate and concrete, which is applied in the field of crushed stone aggregate for concrete and concrete, which can solve the problems of large fluctuations in the quality of crushed stone aggregate, non-reusable resources, and large environmental pollution, so as to achieve reusable resources and reduce The effect of unit weight and quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation and detection of embodiment 1 polyamide resin aggregate

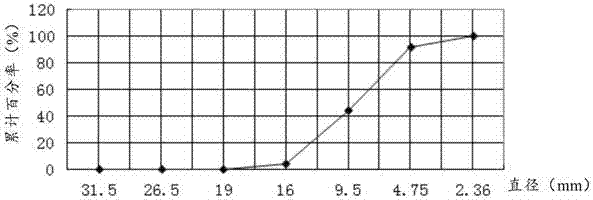

[0043] Polyamide resin aggregates are processed and produced according to the requirements of continuous gradation of 5-16 (mm) in "JGJ52-2006 Standard for Quality and Inspection Methods of Sand and Stone for Ordinary Concrete". The polyamide resin aggregate is rounded by making an injection mold conforming to the continuous gradation of 5-16 (mm), and injection molded at high temperature. The particle gradation range of the polyamide resin aggregate is shown in Table 1, and the particle gradation curve is shown in figure 1 shown.

[0044] Table 1 Particle gradation of polyamide resin aggregate

[0045] diameter (mm) 2.5 5 10 16 Cumulative ratio (%) 100 96 52 4

[0046] Other indicators of polyamide resin aggregates are shown in Table 2.

[0047] Table 2 Other indicators of polyamide resin aggregate

[0048] index mud content Mud content Needle-like parti...

Embodiment 2

[0049] Example 2 Crushed stone aggregate detection

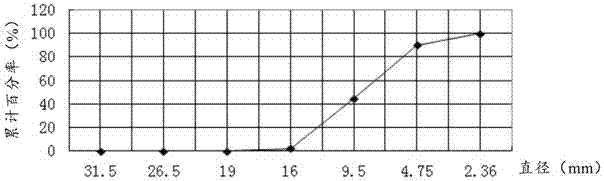

[0050] The crushed stone aggregate has been tested to meet the continuous gradation requirements of 5-16 (mm) in the "JGJ52-2006 Standard for Quality and Inspection Methods of Sand and Stone for Ordinary Concrete". The particle gradation range of crushed stone aggregate is shown in Table 3, and the particle gradation curve is shown in Table 3. figure 2 shown.

[0051] Table 3 Particle gradation of crushed stone aggregate

[0052] diameter (mm) 2.5 5 10 16 Cumulative ratio (%) 100 90 45 2

[0053] Other indicators of crushed stone aggregates are shown in Table 4.

[0054] Table 4 Other indicators of crushed stone aggregate

[0055] index mud content Mud content Needle-like particle content Compressive strength gravel aggregate 0.5% 0% 4% 70 MPa

Embodiment 3

[0056] Embodiment 3 adopts polyamide resin aggregate and crushed stone aggregate to prepare concrete respectively

[0057] 1. Raw material and ratio

[0058] Polyamide resin aggregates and crushed stone aggregates were used to prepare concrete, and the mixing ratio of each raw material was carried out with reference to Table 5, which met the requirements of the JGJ55-2011 standard of "Common Concrete Combination Design Regulations". The tested polyamide resin aggregate has a density of 1450kg / m 3 , the density of crushed stone aggregate is 2640kg / m 3 , using the method of equal volume replacement, first calculate the volume of crushed stone in each square of concrete, and calculate the amount of resin aggregate according to the density of resin aggregate and the volume to be filled, that is: volume * density = quantity, Due to the large difference in the density of the two different aggregates, the calculated unilateral dosage also has a large difference.

[0059] Table 5 R...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com