A Method of Improving the Machining Accuracy of Internal Gear Honing Wheel Power Honing

A technology of machining precision and tooth honing, which is applied in the field of improving the machining precision of internal gear honing wheels for powerful tooth honing, can solve problems such as unpredictable tooth surface profile error, machine tool damage, and inability to comprehensively model problems with multiple indicators, and achieve fast solution speed. , reduce modeling costs, optimize the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Taking microcrystalline corundum internal gear honing wheel honing 20CrMnTi gear as an example, HMX-400 CNC internal gear honing wheel powerful gear honing machine is used. The basic parameters of the gear are: modulus m n =2.25, number of teeth z=73, gear helix angle β=33°, pressure angle α=17.5°. The basic parameters of the internal gear honing wheel are: modulus m n =2.25, number of teeth z=123, honing wheel helix angle β=41.981°, pressure angle α=17.5°. The feeding method is axial and radial continuous feeding. The profile errors of various tooth surfaces are detected by the Klingelnberg-P40 gear measuring center.

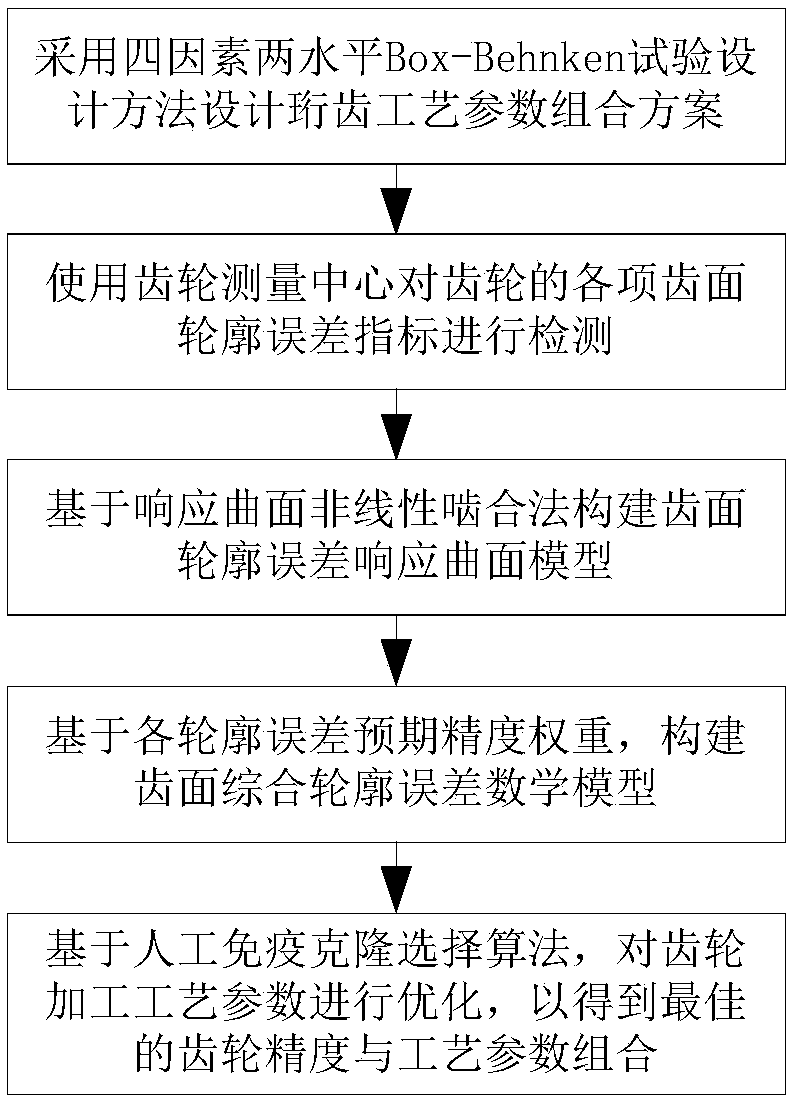

[0051] see figure 1 , an operation step for improving the machining accuracy of internal gear honing wheel power honing is as follows:

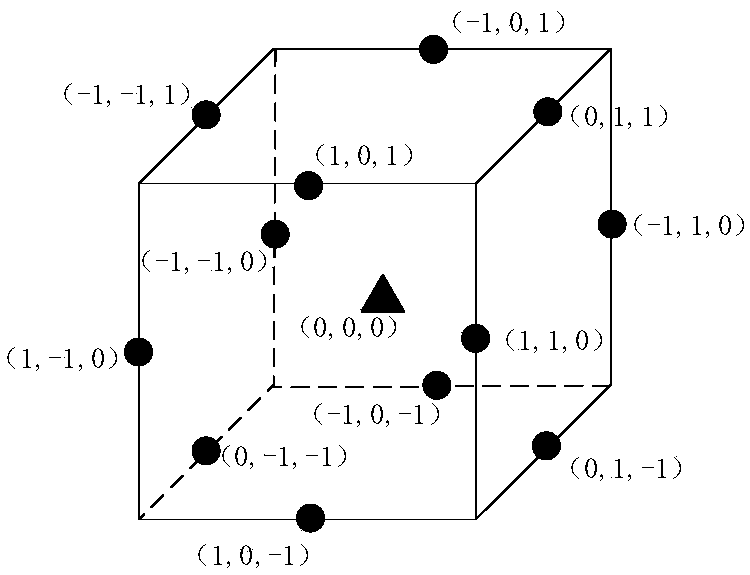

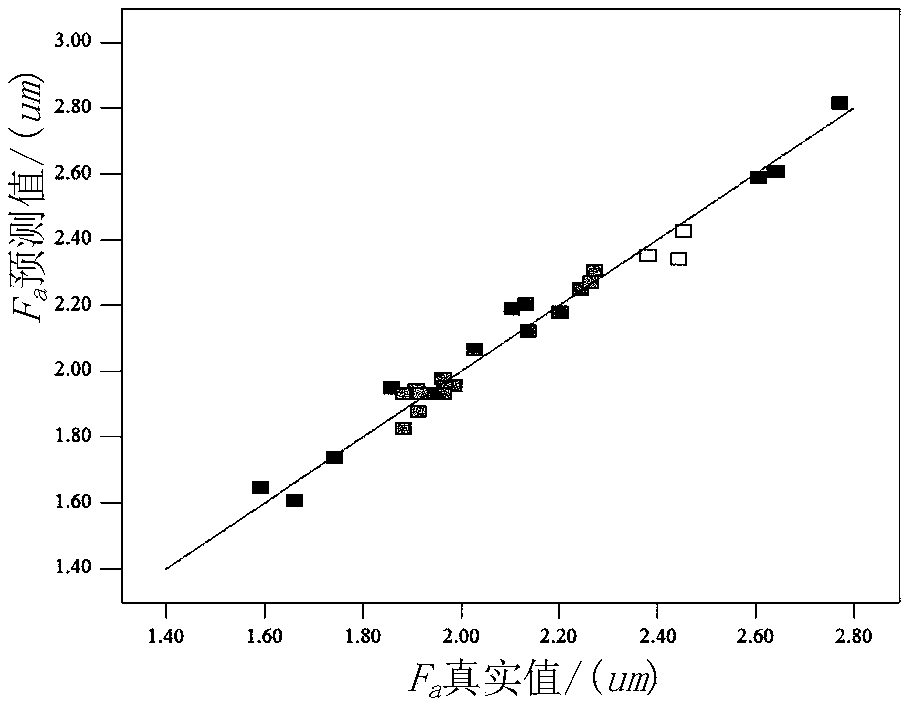

[0052] Step (1), according to the powerful honing process of the internal gear honing wheel of the processed gear, extract the honing process parameters that affect the gear machining accuracy, design the combinati...

Embodiment 2

[0090] 1. Workpiece parameters

[0091] Concrete flow process of the present invention is as figure 1 shown. Taking microcrystalline corundum internal gear honing wheel honing 20CrMnTi gear as an example, HMX-400 CNC internal gear honing wheel powerful gear honing machine is used. The basic parameters of the gear are: modulus m n =2.36, the number of teeth z=18, the gear helix angle β=33°45", the pressure angle α=17°. The basic parameters of the internal tooth honing wheel are: modulus m n =2.36, number of teeth z=95, honing wheel helix angle β=41.696°, pressure angle α=17°. The feeding method is axial and radial continuous feeding. The profile errors of various tooth surfaces are detected by the Klingelnberg-P40 gear measuring center.

[0092] 2. Process parameters

[0093] The ranges of the four gear honing process factors are:

[0094] Work gear speed 20002 X Z S <3(times),

[0095] 3. The operation steps for improving the machining accuracy of the internal gear hon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com