Efficient and anti-explosion three-phase asynchronous motor

A three-phase asynchronous motor technology, applied in the direction of electric components, electromechanical devices, electrical components, etc., can solve the problems of shortening the service life, affecting the power conversion of the motor, etc., and achieves the effect of stable operation, good shockproof effect, and improved stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the present invention and do not limit the protection scope of the present invention.

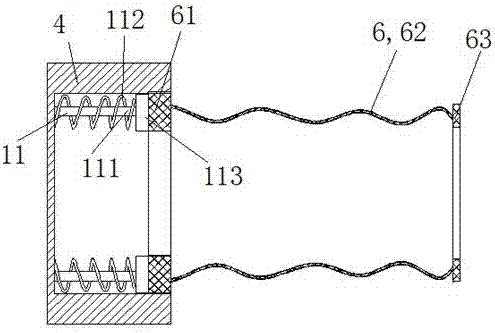

[0018] like figure 1 As shown, the high-efficiency explosion-proof three-phase asynchronous motor includes a rotor 1, a stator 2, a motor housing 3, an end cover 4 and a collector ring 5, and the end of the motor housing 3 facing the end cover 4 is provided with a hollow cushioning cavity 31, the air spring 6 is set inside the hollow cushioning cavity 31, the coolant 7 is filled between the hollow cushioning cavity 31 and the air spring 6, and a motor housing 3 and the hollow cushioning cavity 31 are also provided There are cooling liquid inlet 32 and cooling liquid adding port 33, and cooling liquid inlet 32 and cooling liquid adding port 33 are respectively connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com