Inhaler, Respiratory Tract and Lung Model Device Integration for Sorting Flower-Shaped Particle Carriers

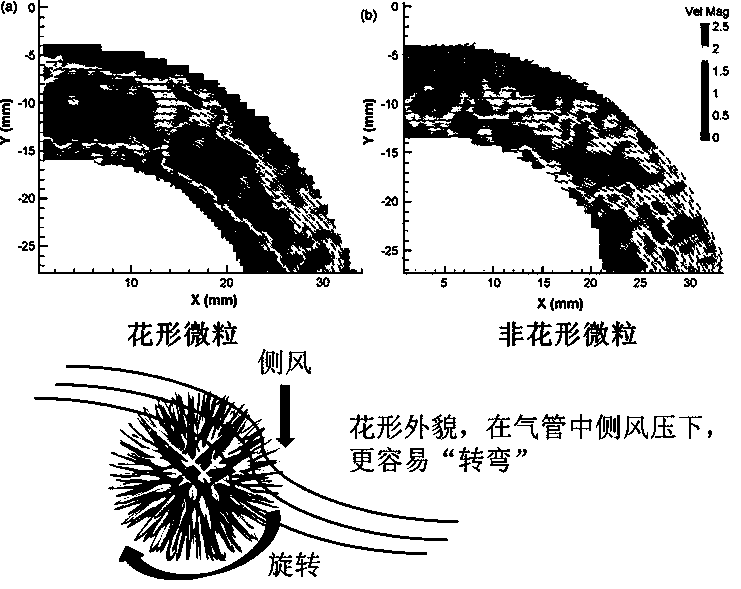

A technology for respiratory tract and inhaler, applied in the field of particle sorter, can solve the problems of inability to separate, difficult to sort out particles with different shapes, and inability to sort particles with different shapes, etc., so as to improve the preparation process and practicality high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Such as figure 1 (Schematic diagram of the structure of the inhaler, respiratory and lung model equipment for sorting flower-shaped particle carriers) As shown in the figure, the integration of inhaler, respiratory and lung model equipment for sorting flower-shaped particle carriers mainly includes inhaler (1), respiratory model Equipment (2), Particle Collector for Respiratory Section Curve (3), Lung Model Equipment (4), Particle Collector for Right Curve of Lung Model (5), Particle Collector for Left Curve of Lung Model (6) ) and air pump (7), the air outlet of the inhaler (1) communicates with the air inlet of the airway model equipment (2), and the middle and lower part of the inner bend of the airway model equipment (2) is connected with the respiratory section bend particle collector (3) The inlet of the airway model equipment (2) is connected to the air inlet of the lung model equipment (4), and the middle and lower parts of the right bends in the airway of the l...

Embodiment 2

[0040]The gas flow rate of the whole system during operation is 30L / min.

[0041] Furthermore, the mixed particle carrier powder to be sorted into the powder inlet (1-1) is mainly composed of flower-shaped lactose particles and lactose monohydrate crystal particles, and the gas entering the inhaler inlet (1-2) is dry room temperature Air, the inhaler grille (1-4) has a side length of 30mm and 100 round holes with a diameter of 2mm.

[0042] Further, the feed valve (3-1) is in an open state, the right first-stage valve (5-1), the right second-stage valve (5-2), the right third-stage valve (5-3), Right fourth stage valve (5-4), left first stage valve (6-1), left second stage valve (6-2), left third stage valve (6-3) and left The fourth-stage valves (6-4) are all closed, corresponding to the coarse separation mode.

[0043] Further, the filter pore size of the particulate filter membrane (4-12) is 1 µm.

[0044] Other processes not listed in Example 2 are the same as those des...

Embodiment 3

[0047] The gas flow rate of the whole system during operation is 100L / min.

[0048] Further, the mixed particle carrier powder to be sorted into the powder inlet (1-1) is mainly composed of rough concave mannitol particles and spherical sucrose particles, and the gas entering the inhaler inlet (1-2) is 15 degrees For dry air, the inhaler grille (1-4) has a side length of 20 mm and has 40 square holes with a side length of 3 mm.

[0049] Further, the grain feeding valve (3-1) is in a closed state, the first-stage valve on the right (5-1), the second-stage valve on the right (5-2), the third-stage valve on the right (5-3), Right fourth stage valve (5-4), left first stage valve (6-1), left second stage valve (6-2), left third stage valve (6-3) and left The fourth-stage valves (6-4) are all opened, which corresponds to the fine separation mode without classification.

[0050] Furthermore, the filter pore size of the particulate filter membrane (4-12) is 0.8 µm.

[0051] Other p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com