An induction furnace for high-efficiency horizontal continuous casting

A horizontal continuous casting and induction furnace technology, applied in furnaces, crucible furnaces, furnace types, etc., can solve the problems of low melting rate, high local temperature of melting furnace, strong electromagnetic pollution, etc., to improve production efficiency, accelerate melting rate, Effective work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

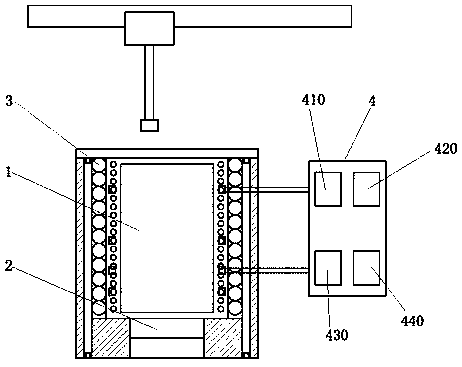

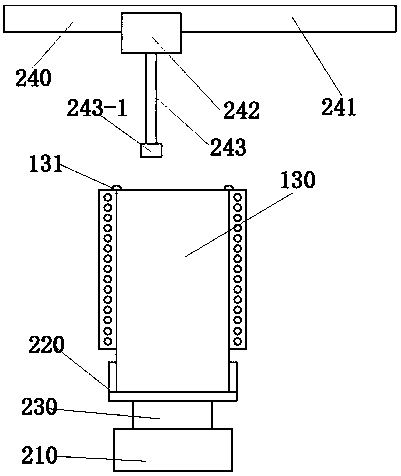

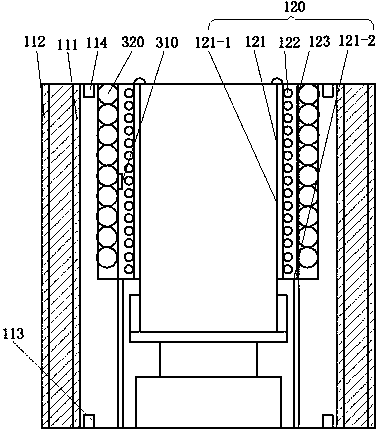

[0022] Please refer to Figure 1-Figure 3 , figure 1 A schematic diagram of the overall structure of an induction furnace for high-efficiency horizontal continuous casting is provided for the present invention; figure 2 Furnace body is provided for the present invention, the schematic diagram of installation structure of tilting furnace system; image 3 A schematic diagram of the installation structure of the induction body and the water cooling system is provided for the present invention.

[0023] Specifically, this embodiment provides an induction furnace for high-efficiency horizontal continuous casting, including: a furnace body 1, a furnace tilting system 2, a water cooling system 3, and an electrical system 4; wherein, the furnace body 1 includes: a shell 110, an induction body 120, and a storage container 130 for smelting; wherein, the storage container 130 for smelting is installed in the housing 110; the induction body 120 consists of an iron core 121, a coil 122,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com