Muffler provided with double exhaust pipes

A dual exhaust pipe and muffler technology, which is applied to exhaust devices, mufflers, machines/engines, etc., can solve the problems of increased engine power loss, inability to guarantee the volume of the muffler, and reduced reliability of the muffler, so as to reduce the pressure loss. , Wide range of noise reduction, the effect of noise cancellation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

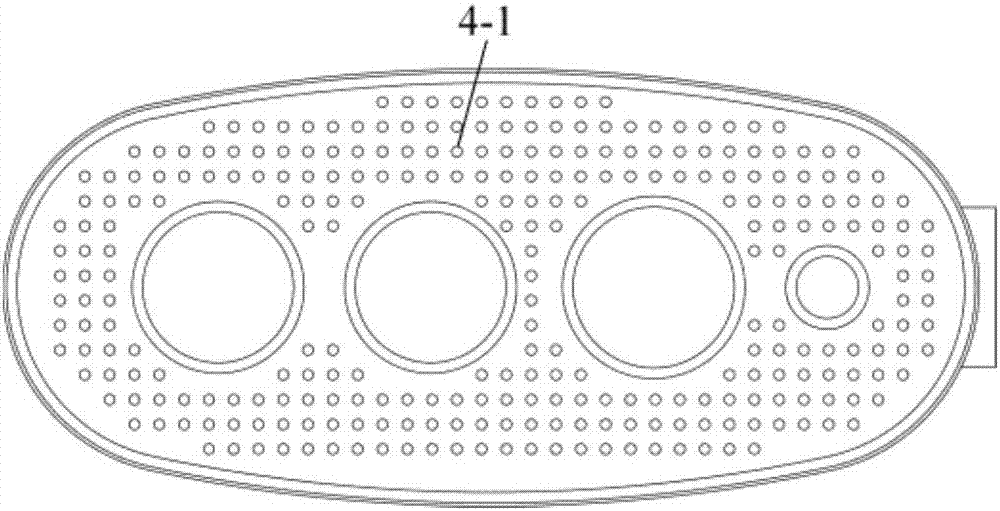

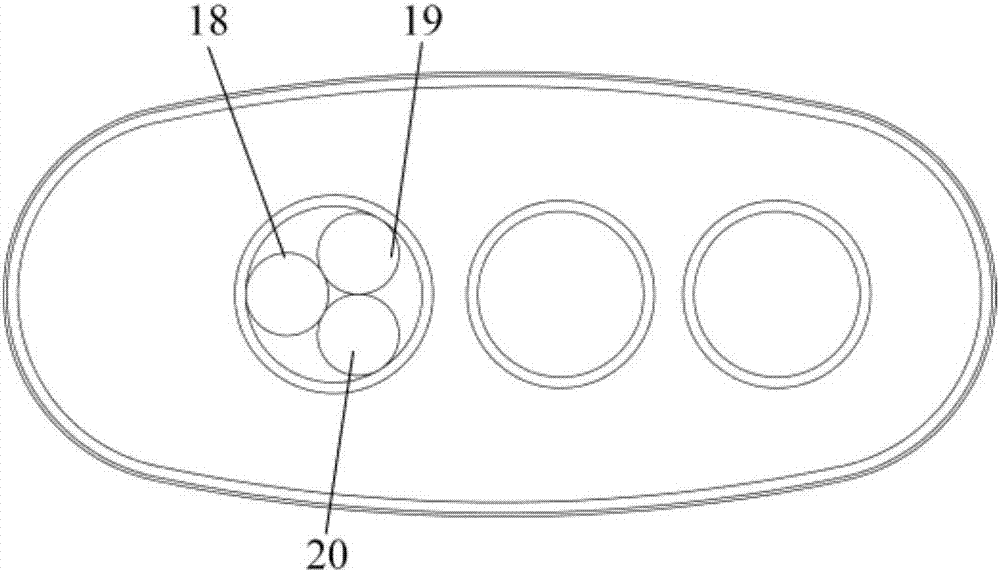

[0023] Such as figure 1 As shown, the present invention is a double exhaust pipe muffler, comprising a shell 1 with an elliptical cross section, a first end cover 2 and a second end cover 3 respectively fixed at both ends of the shell 1, along the shell The body 1 is arranged at intervals in the axial direction of the first partition plate 4, the second partition plate 5 and the third partition plate 6, the intake pipe 11, the left exhaust pipe 14, the right exhaust pipe 15, several diversion tube. Wherein, the edges of the first partition 4, the second partition 5 and the third partition 6 are all provided with flanges, and the first partition 4 and the third partition 6 are also provided with flanges. There are evenly distributed third through holes 4-1 (see figure 2 ) and the fourth through hole 6-1 (see Figure 4 ), wherein the diameter of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com