Bridge girder erection machine capable of realizing on-girder whole-hole two-way erection of large-tonnage asymmetric different-width precast box girder

An asymmetric, large-tonnage technology, which is applied in the direction of erecting/assembling bridges, bridge construction, bridges, etc., can solve the problem of unstable erection of large-tonnage asymmetrical box girders, large-tonnage double-width box girders with many auxiliary facilities, and the inability to carry out double-width beams in one hole Problems such as erecting beams to achieve the effect of improving equipment operation efficiency, meeting erection requirements and safety, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

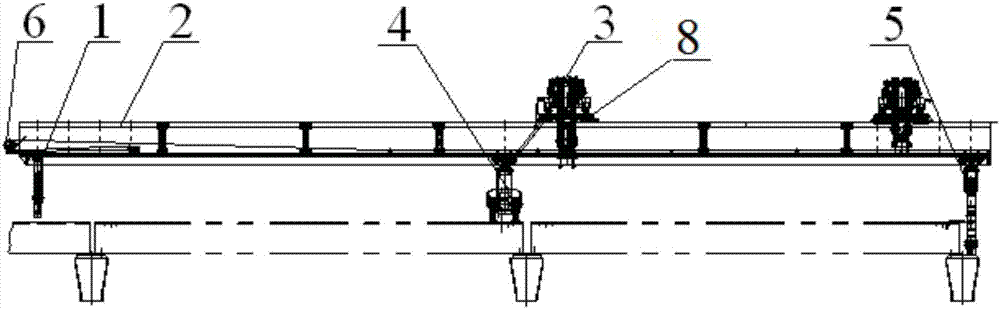

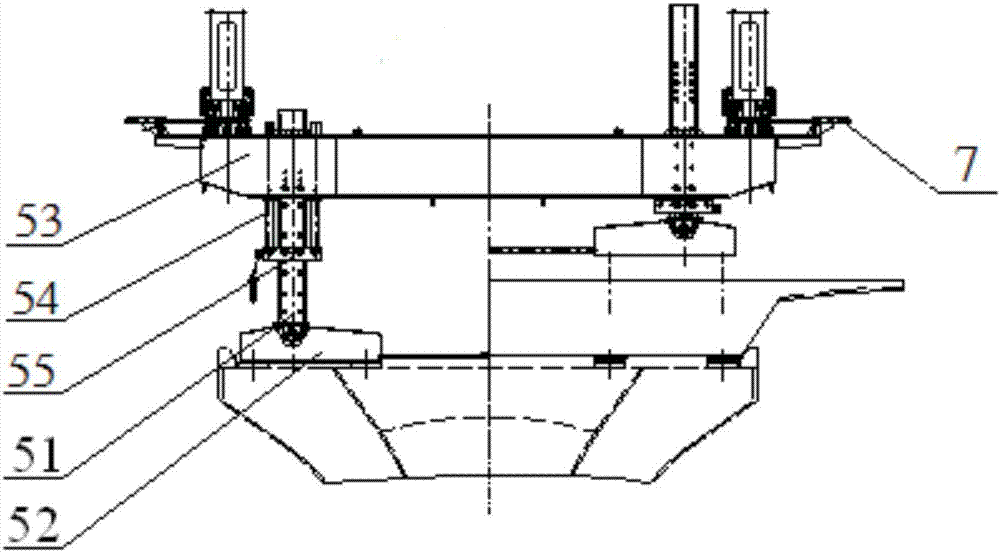

[0041] Such as Figure 1-2 As shown, a bridge erecting machine that can realize the two-way erection of the whole hole on the large-tonnage asymmetric framed prefabricated box girder includes a machine arm 2 designed symmetrically along the longitudinal and transverse directions, and the front arm 2 is provided with The outrigger 5, the middle outrigger 4 and the rear outrigger 1, the front outrigger 5, the middle outrigger 4 and the rear outrigger 1 are respectively connected with the machine arm 2 through a latch locking device 7, so The front and rear trolleys 8 that run longitud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com