q690d medium-thick steel plate and production method for reducing energy consumption of q690d medium-thick steel plate

A production method and thick steel plate technology, applied in the field of metal processing, can solve problems such as adverse effects on mechanical properties and coarse grains, and achieve the effects of easy promotion, excellent mechanical properties, and reduced production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

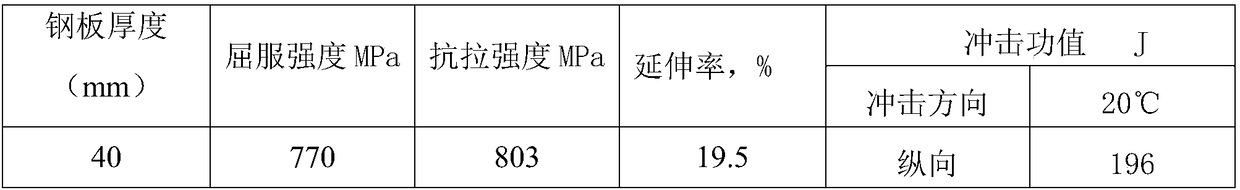

Embodiment 1

[0037] Use a slab with a thickness of 300mm and roll it into a thick steel plate with a thickness of 40mm. The temperature of the slab out of the furnace is 1220°C, and the heating time of the slab is 240 minutes. The slab is cast from the casting machine. The surface is sprayed with water for laminar cooling. During laminar cooling, the water flow density on the upper surface of the slab is 150l / (min m^2), the ratio of the water flow density on the upper and lower surfaces of the slab is 1:3, and the cooling time is 100 Second. When entering the furnace, the surface turns red and the temperature is 720°C. The (weight percent) chemical composition of the slab is: C 0.12%, Si 0.25%, Mn 1.65%, Nb: 0.04%; V: 0.06%; Cr0.25%; Mo0.25%; P0.02%, S 0.007 %, Als0.017%, Ca0.001%, Ti0.01%; the balance is Fe and unavoidable impurities. The rolling temperature of the first stage is 1210°C. The first-stage rolling speed is 0.8m / s, the first-stage final rolling temperature is 1120°C, and t...

Embodiment 2

[0041] A slab with a thickness of 300mm is used to roll it into a thick steel plate with a thickness of 60mm. The temperature of the slab out of the furnace is 1240°C, and the heating time of the slab is 300 minutes. The slab is cast from the casting machine. The surface is sprayed with water for laminar cooling. During laminar cooling, the water flow density on the upper surface of the slab is 165l / (min m^2), the ratio of the water flow density on the upper and lower surfaces of the slab is 1:3, and the cooling time is 150 Second. When entering the furnace, the surface turns red and the temperature is 670°C. The (weight percent) chemical composition of the slab is: C 0.14%, Si 0.35%, Mn 1.75%, Nb: 0.05%; V: 0.08%; Cr0.35%; Mo0.35%; P0.012%, S 0.03 %, Als0.027%, Ca0.0015%, Ti0.02%; the balance is Fe and unavoidable impurities. The rolling temperature of the first stage is 1210°C. The first-stage rolling speed is 0.8m / s, the first-stage final rolling temperature is 1158°C, a...

Embodiment 3

[0045] Use a slab with a thickness of 300mm and roll it into a thick steel plate with a thickness of 50mm. The temperature of the slab out of the furnace is 1232°C, and the heating time of the slab is 285 minutes. The slab is cast from the casting machine. The surface is sprayed with water for laminar cooling. During laminar cooling, the water flow density on the upper surface of the slab is 167l / (min m^2), the ratio of the water flow density on the upper and lower surfaces of the slab is 1:3, and the cooling time is 120 Second. When it enters the furnace, the surface turns red and the temperature is 689°C. The (weight percent) chemical composition of the slab is: C 0.13%, Si 0.3%, Mn 1.71%, Nb: 0.045%; V: 0.065%; Cr0.3%; Mo0.3%; P0.013%, S 0.003 %, Als0.022%, Ca0.0012%, Ti0.014%; the balance is Fe and unavoidable impurities. The rolling temperature of the first stage is 1222°C. The rolling speed in the first stage is 0.8m / s, the final rolling temperature in the first stage...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com