Magnetizing roasting method for complex refractory mixed type iron ore

A technology of magnetization roasting and composite magnetization, applied in the fields of mineral processing and metallurgy, can solve the problems of poor magnetic separation index, complex magnetic separation process of mixed iron ore, high roasting and magnetic separation cost, achieve energy saving and emission reduction effect, reduce magnetization Roasting cost, the effect of easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

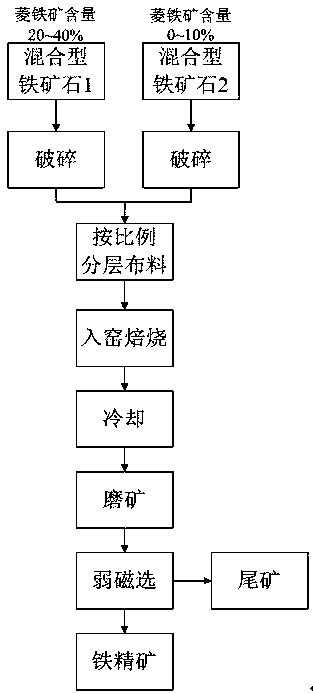

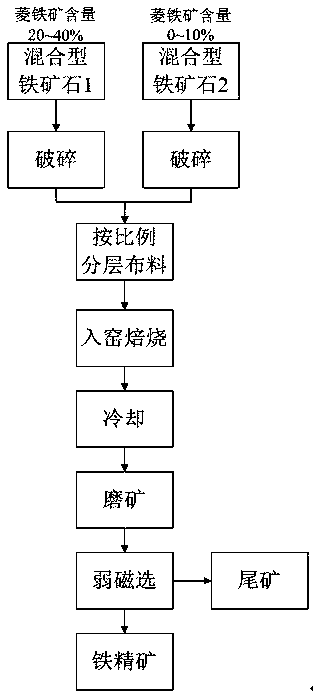

[0044] A magnetization roasting method for complex refractory mixed iron ore, comprising the following steps:

[0045] Step 1: Separate a certain mine The siderite content of the ore body is 20%, the total iron grade is 33.71%, and the mixed iron ore with the Ⅷ ore body siderite content of 5%, and the total iron grade is 32.48% are all crushed to 20mm;

[0046] Step 2: Weigh 20mm 200g of ore body iron ore is spread on the lower layer of the roasting tank, 200g of 20mm Ⅷ ore body iron ore is weighed and spread on the upper layer of the roasting tank, and the surface layer of the Ⅷ ore body iron ore is covered with 20g of semi-coke;

[0047] Step 3: Control the temperature of the box-type resistance furnace to 850°C, start roasting, and roast for 50 minutes;

[0048] Step 4: After the roasting is finished, take out the roasting tank, seal it with water and cool it to room temperature;

[0049] Step 5: The cooled mixed material is crushed and ground, and the grinding particl...

Embodiment 2

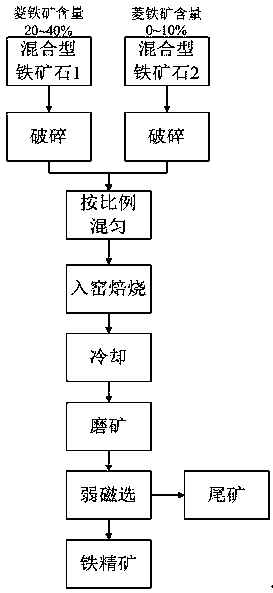

[0052] A magnetization roasting method for complex refractory mixed iron ore, comprising the following steps:

[0053] Step 1: Separate a certain mine The siderite content of the ore body is 20%, the total iron grade is 33.71%, and the mixed iron ore with the Ⅷ ore body siderite content of 5%, and the total iron grade is 32.48% are all crushed to 30mm;

[0054] Step 2: Weigh 30mm 500g of ore body iron ore and 500g of 30mm Ⅷ ore body iron ore, and then mix the two kinds of iron ore;

[0055] Step 3: Control the kiln temperature in the roasting section of the rotary kiln to 750°C, the rotating speed to 90s / r, the filling rate to 25%, and the roasting time in the high-temperature section to 20 minutes, and start roasting in the kiln;

[0056] Step 4: After all the roasted ore enters the cooling section of the rotary kiln, the power is turned off to cool down, and the cooling section is sealed and air-cooled before unloading;

[0057] Step 5: The cooled mixed material is crus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com