Self-adhered asphalt and preparation method thereof and self-adhered asphalt waterproof roll

A technology of asphalt waterproof membrane and self-adhesive asphalt, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of decreased cohesion, detachment from the base layer, and difficulty in curing building leakage, so as to improve the resistance to damage sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0030] According to a preferred embodiment, the preparation method specifically includes the following steps:

[0031] 1) Add the high-grade liquid asphalt, liquid viscosity-increasing agent and viscosity-reducing agent into the reaction kettle, and raise the temperature to 100-150°C (preferably 135-145°C);

[0032] 2) Add SIS and SBS, heat up to 170-185°C (more preferably 175-180°C), and homogenize at a high speed within this temperature range for 0.8-1.2h;

[0033] 3) adding light calcium carbonate and stirring for 0.5-1 hour, and then adding antioxidant and stirring for 0.2-0.6 hours, so as to prepare the self-adhesive asphalt.

[0034] According to the third aspect of the present invention, the present invention provides a self-adhesive asphalt waterproofing membrane, the self-adhesive asphalt waterproofing membrane comprising the self-adhesive asphalt described in the present invention.

[0035] According to a preferred embodiment, the self-adhesive asphalt waterproofing...

Embodiment 1

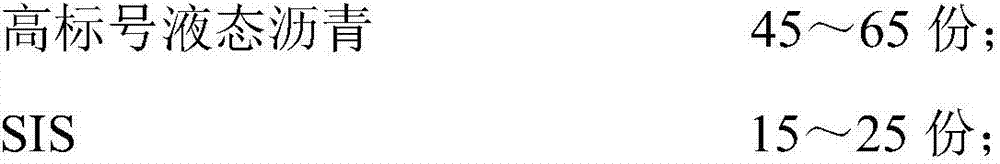

[0044] 1) Raw material formula (by weight) of self-adhesive asphalt:

[0045]

[0046] 2) The preparation method is:

[0047]Add the above-mentioned high-grade liquid asphalt, liquid tackifier and viscosity reducer into the reaction kettle, raise the temperature to 140°C, add SIS and powdered SBS, raise the temperature to 175-180°C, and homogenize at a high speed within this temperature range for 1.0h ; Then add light calcium carbonate and stir for 0.6h, and finally add antioxidant and stir for 0.3h to obtain self-adhesive asphalt.

[0048] The typical performance indicators of the product are softening point of 88°C, low temperature flexibility of -30°C, peel strength of 2.51N / mm, self-healing time of 2 seconds at standard ambient temperature, and 5 seconds of self-healing time at 5°C; ℃ and 10 ℃ are bonded to the cement board, and the fatigue resistance is 100 times of vibration without water seepage.

Embodiment 2

[0050] 1) Raw material formula (by weight) of self-adhesive asphalt:

[0051]

[0052] 2) The preparation method is:

[0053] Add the above-mentioned high-grade liquid asphalt, liquid tackifier and viscosity reducer into the reaction kettle, raise the temperature to 140°C, add SIS and powdered SBS, raise the temperature to 175-180°C, and homogenize at a high speed within this temperature range for 0.8h ; Then add light calcium carbonate and stir for 0.6h, and finally add antioxidant and stir for 0.4h to obtain self-adhesive asphalt.

[0054] The typical performance indicators of the product are softening point of 8°C, low temperature flexibility of -32°C, peel strength of 2.57N / mm, self-healing time of 2 seconds at standard ambient temperature, and 3 seconds of self-healing time at 5°C; ℃ and 10 ℃ are bonded to the cement board, and the fatigue resistance is 100 times of vibration without water seepage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Low temperature flexible | aaaaa | aaaaa |

| Peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com