Method for preparing natural protein compound micelle with disulfide bond reconstruction method

A technology of composite micelles and natural proteins, which is applied in the field of preparing natural protein composite micelles by disulfide bond reconstruction method, can solve the problems of slow metabolism rate, limited function and accumulation, and achieves good biocompatibility and metabolizable products. , the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

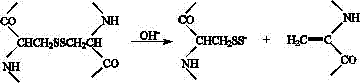

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing natural protein complex micelles by a disulfide bond reconstruction method, comprising the steps of:

[0027] ① Preparation of mass concentration of 0.5% keratin solution; keratin through Na 2 Prepared by S reduction and acid precipitation method, the method is as follows: a. Combine degreased and washed wool or animal hoof horn powder with Na 2 S is added to a closed glass container according to the mass ratio of 4:3, water with 20 times the mass of wool or hoof horn powder is added, and the keratin solution is obtained by placing it in the dark for 10 days; b. Add concentrated hydrochloric acid to the keratin solution within 20 seconds to make The pH value of the keratin solution reaches 2.0-2.5 within 30 seconds, causing the keratin to precipitate rapidly; c. After the keratin is precipitated, the keratin precipitate in the lower layer is collected, washed twice with anaerobic water, and vacuum-dried at 5°C to obtain white keratin Protein soli...

Embodiment 2

[0031] A method for preparing natural protein complex micelles by a disulfide bond reconstruction method, comprising the steps of:

[0032] ① Preparation of mass concentration of 5% keratin solution; keratin through Na 2 Prepared by S reduction and acid precipitation method, the method is as follows: a. Combine degreased and washed wool or animal hoof horn powder with Na 2 S is added to a closed glass container according to the mass ratio of 4:3, water with 20 times the mass of wool or hoof horn powder is added, and the keratin solution is obtained by keeping it in the dark for 7-10 days; b. Add concentrated hydrochloric acid to the keratin solution within 20 seconds , so that the pH value of the keratin solution reaches 2.0-2.5 within 60 seconds, so that the keratin precipitates rapidly; c. After the keratin precipitates, the keratin precipitate in the lower layer is collected, washed 4 times with anaerobic water, and vacuum-dried at 20°C to obtain White keratin solid powder...

Embodiment 3

[0036] A method for preparing natural protein complex micelles by a disulfide bond reconstruction method, comprising the steps of:

[0037] ① Preparation of mass concentration of 2.5% keratin solution; keratin through Na 2 Prepared by S reduction and acid precipitation method, the method is as follows: a. Combine degreased and washed wool or animal hoof horn powder with Na 2 S is added into a closed glass container according to the mass ratio of 4:3, water with 18 times the weight of wool or hoof horn powder is added, and the keratin solution is obtained by placing it in the dark for 8 days; b. Add concentrated hydrochloric acid in the keratin solution within 20 seconds to make The pH value of the keratin solution reaches 2.0-2.5 within 40 seconds, causing the keratin to precipitate rapidly; c. After the keratin is precipitated, the keratin precipitate in the lower layer is collected, washed 3 times with anaerobic water, and vacuum-dried at 20°C to obtain white keratin Protei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com