Sulfate-type hydrophilic chain extender and preparation method thereof

A technology of hydrophilic chain extender and sulfate ester salt, applied in sulfate ester preparation, organic chemistry and other directions, can solve the problems such as reports of sulfate ester salt type hydrophilic chain extender that have not been seen, and achieve excellent electrolyte resistance and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

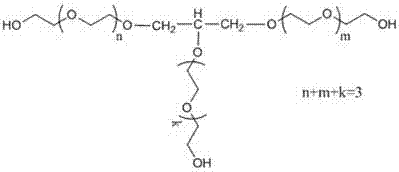

[0039] (1) Polyether polyol PEG-1 (see figure 1 ) and sulfamic acid are placed in a reaction flask in a molar ratio of 1:1.5, protected by nitrogen gas, slowly heated to 90° C., kept for 2 hours, and monitored for anion content close to the theoretical value;

[0040] (2) Cool down to below 50°C, add solvent methanol to dissolve, filter, collect the filtrate, and distill under reduced pressure to obtain a concentrated solution;

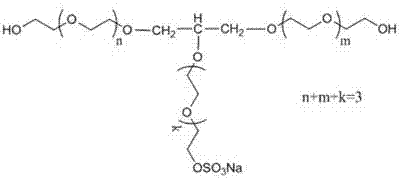

[0041] (3) Add solvent acetone to the concentrated solution, and neutralize with excess sodium hydroxide to ensure that the solution is weakly alkaline, stir evenly, filter under reduced pressure, collect the filtrate, and then distill the filtrate under reduced pressure to obtain a viscous liquid that is Sulphate salt type hydrophilic chain extender S-1, its structural formula is as follows figure 2 shown.

Embodiment 2

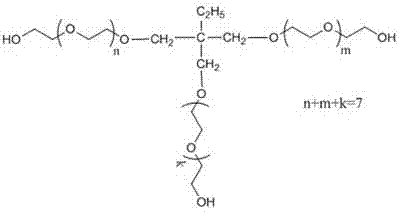

[0043] (1) Polyether polyol PEG-2 (see image 3 ) and sulfamic acid are placed in a reaction flask in a molar ratio of 1:1.5, placed in the reaction flask, protected by nitrogen gas, slowly heated to 90° C., kept for 3 hours, and the anion content is monitored to approach the theoretical value;

[0044] (2) Cool down to below 50°C, add solvent ethanol to dissolve, filter, collect the filtrate, and distill under reduced pressure to obtain a concentrated solution;

[0045] (3) Add solvent acetone to the concentrated solution, and neutralize with excess sodium carbonate to ensure that the solution is weakly alkaline, stir evenly, filter under reduced pressure, collect the filtrate, and then distill the filtrate under reduced pressure to obtain a viscous liquid that is sulfuric acid Ester salt type hydrophilic chain extender S-2, its structural formula is as follows Figure 4 shown.

Embodiment 3

[0047] (1) Polyether polyol PPG-1 (see Figure 5 ) and sulfamic acid are placed in a reaction flask in a molar ratio of 1:1.2, protected by nitrogen gas, slowly heated to 90° C., kept for 4 hours, and the anion content is monitored to be close to the theoretical value;

[0048] (2) Cool down to below 50°C, add solvent isopropanol to dissolve, filter, collect filtrate, and distill under reduced pressure to obtain concentrated solution;

[0049] (3) Add solvent butanone to the concentrated solution, and neutralize with excess sodium carbonate to ensure that the solution is weakly alkaline, stir evenly, filter under reduced pressure, collect the filtrate, and then distill the filtrate under reduced pressure to obtain a viscous liquid that is Sulphate salt type hydrophilic chain extender S-3, its structural formula is as follows Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com