Experiment device for simulating natural gas hydrate formation well cementation

An experimental device, natural gas technology, applied in teaching models, wellbore/well components, production fluids, etc., can solve problems such as data collection and analysis of hydration heat of cement slurry that cannot be cemented, so as to enhance independent innovation capabilities and fill technical gaps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the purpose, technical solution and advantages of the present invention more clear, the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

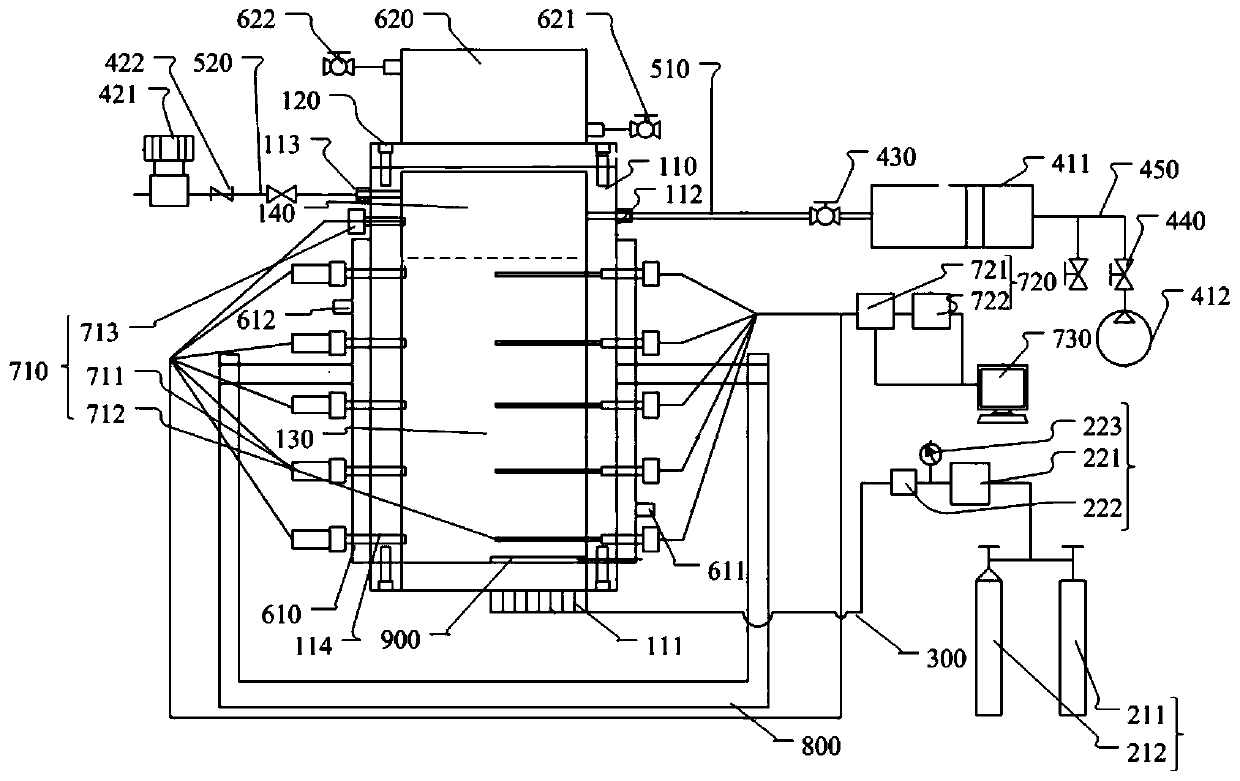

[0016] In an exemplary embodiment, the embodiment of the present invention provides an experimental device for simulating natural gas hydrate formation cementing, including: a kettle body 100, a gas-liquid pressurized injection system 200, a cement slurry injection system 400, and a temperature control system and data processing systems.

[0017] The kettle body 100 includes a kettle barrel 110 and a kettle cover 120 . The kettle barrel 110 includes a first space 130 for filling the formation skeleton simulant and a second space 140 for injecting cement slurry, and the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com