Micro-expanded fireproof heat-insulating mortar and preparation method thereof

A fire-proof and thermal insulation mortar and micro-expansion technology, which is applied in the field of mortar preparation, can solve the problems of mortar shrinkage and deformation, cracks, etc., and achieve the effects of good thermal insulation performance, small linear shrinkage rate, and excellent crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

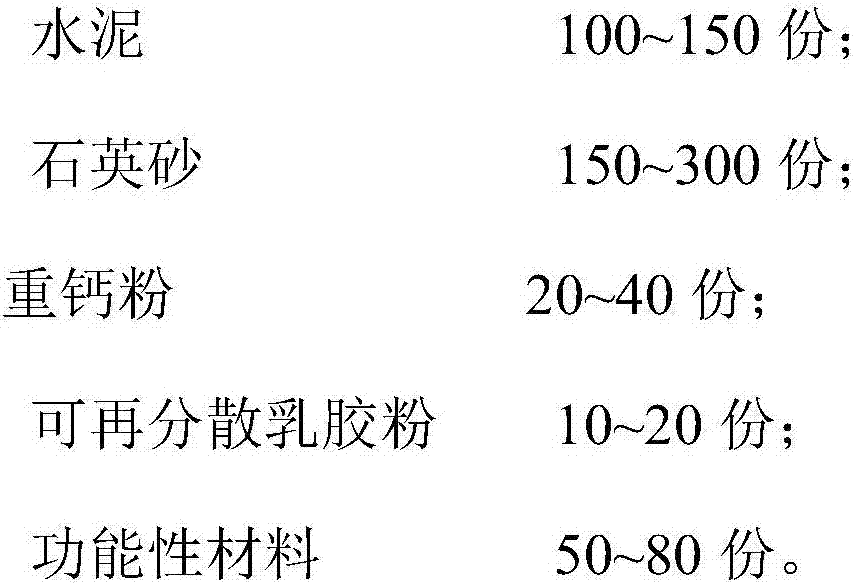

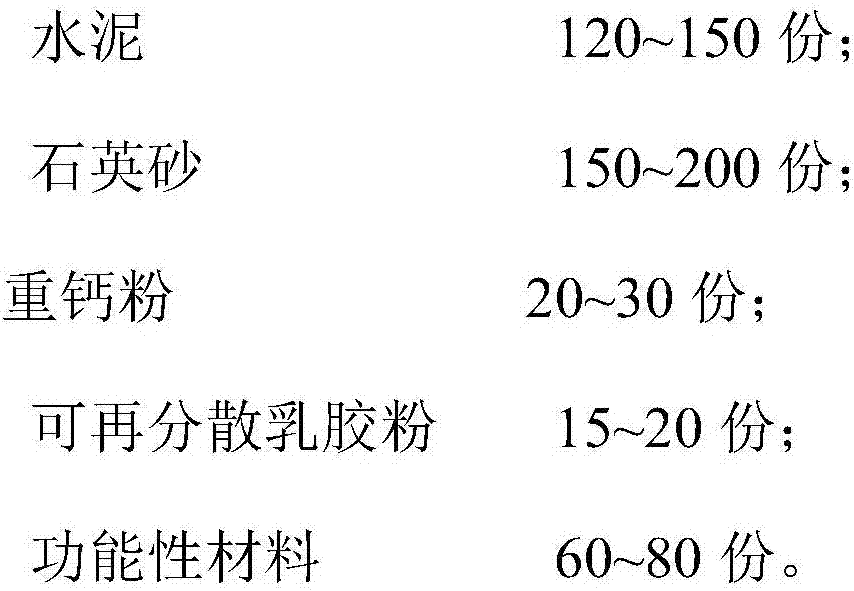

Method used

Image

Examples

Embodiment 1

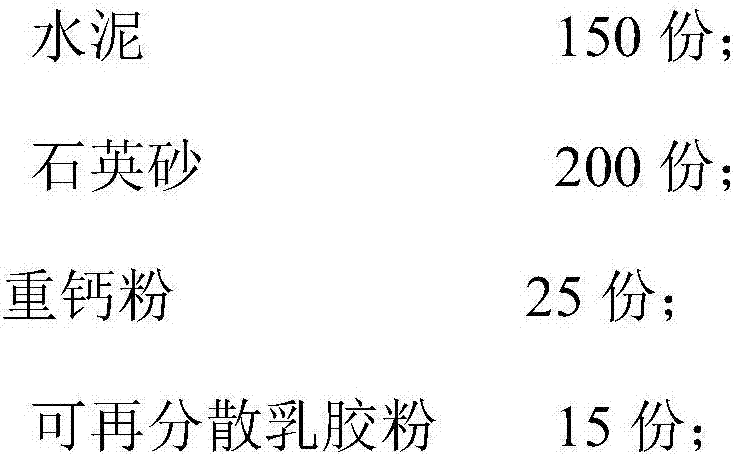

[0028] Example 1 Preparation of micro-expansion fireproof and thermal insulation mortar

[0029] Component weight ratio: 150 parts of cement; 200 parts of quartz sand; 25 parts of heavy calcium powder; 15 parts of redispersible latex powder; 70 parts of functional materials;

[0030] The weight ratio of the functional material components: 50 parts of vitrified microbeads; 50 parts of vermiculite; 15 parts of lignin; 5 parts of graphite powder;

[0031] Preparation method: Mix cement, quartz sand, redispersible latex powder, heavy calcium powder and functional materials, and stir evenly.

Embodiment 2

[0032] Example 2 Preparation of micro-expansion fireproof and thermal insulation mortar

[0033] Component weight ratio: 150 parts of cement; 200 parts of quartz sand; 25 parts of heavy calcium powder; 15 parts of redispersible latex powder; 70 parts of functional materials;

[0034] The weight ratio of the functional material components: 30 parts of vitrified microbeads; 30 parts of vermiculite; 20 parts of lignin; 10 parts of graphite powder;

[0035] Preparation method: Mix cement, quartz sand, redispersible latex powder, heavy calcium powder and functional materials, and stir evenly.

Embodiment 3

[0036] Example 3 Preparation of micro-expansion fireproof and thermal insulation mortar

[0037] Component weight ratio: 120 parts of cement; 200 parts of quartz sand; 20 parts of heavy calcium powder; 20 parts of redispersible latex powder; 60 parts of functional materials;

[0038] The weight ratio of the functional material components: 50 parts of vitrified microbeads; 50 parts of vermiculite; 15 parts of lignin; 5 parts of graphite powder;

[0039] Preparation method: Mix cement, quartz sand, redispersible latex powder, heavy calcium powder and functional materials, and stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com