Automatic feeding and cutting device of glass rod material

An automatic feeding and cutting device technology, applied in glass cutting devices, glass production, glass manufacturing equipment, etc., can solve the problems of short length of glass rods and inapplicable batch cutting of glass rods, and achieve the goal of improving product quality and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

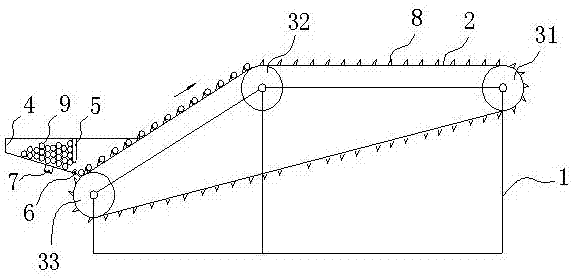

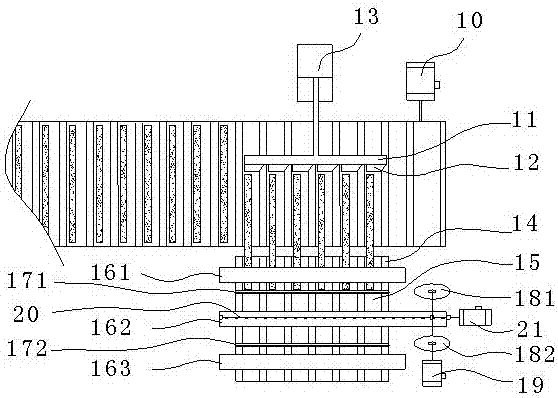

[0017] Such as figure 1 with figure 2 As shown, the glass rod automatic feeding and cutting device provided by the present invention includes a frame 1 and a feeding system, a cutting system and a control system installed on the frame 1 .

[0018] The feeding system comprises a collection box 4, a conveyor belt 2, a driving wheel 31, a driven wheel 33, a tensioning wheel 32, a servo motor 10, a pushing plate 11, and a pushing cylinder 13. The collection box 4 is arranged on the frame 1 at one end of the conveyor belt 2. The width of the inner cavity of the collection box 4 is slightly larger than the width of the conveyor belt 2. A vibrator 7 is installed on the outer surface of one of the tapered side plates, and the bottom is installed at the junction of the conveyor belt 2. There is a movable transition plate 6 with a rotating shaft, and a height-adjustable material blocking plate 5 with an arc-shaped edge is installed from the top of the rotating shaft to the mouth of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com