Flattening type vegetable winnowing machine

A winnowing machine, flat-laying technology, applied in the direction of solid separation, separating solids from solids with airflow, chemical instruments and methods, etc., can solve the problem of winnowing machine not removing dust, low operating efficiency, vegetable winnowing Not applicable etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

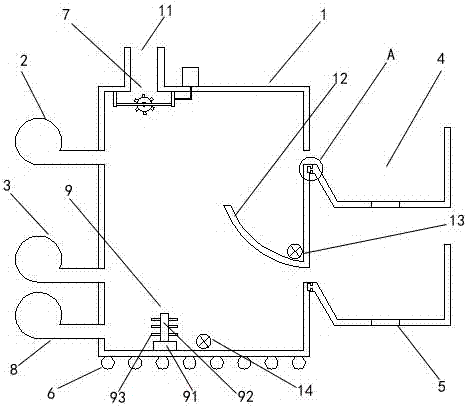

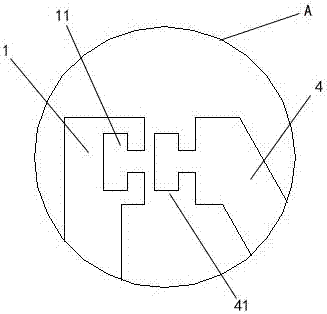

[0018] Such as figure 1 As shown, a tiled vegetable winnowing machine includes a body 1, an upper fan 2, a lower fan 3, an upper dust collection tank 4, a lower dust collection tank 5, a breaking mechanism 7, a bottom fan 8, and a tiling mechanism 9 . The upper end side of the body 1 is provided with a material inlet 11 . An upper fan 2 and a lower fan 3 are respectively installed on the upper and lower parts of one side of the body 1 . The upper fan 2 and the lower fan 3 are located on one side of the material inlet 11 . The upper part and the lower part of the other side of the body 1 are respectively equipped with an upper dust collecting tank 4 and a lower dust collecting tank 5 . The upper dust collection tank 4 and the lower dust collection tank 5 communicate with the other side of the machine body 1 . The inside of the body 1 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com