Chemical reaction kettle with high work quality

A chemical reaction and work quality technology, applied in chemical/physical/physicochemical fixed reactors, chemical instruments and methods, control/regulation processes, etc. The improvement is not obvious, and the quality of material reaction is reduced, so as to reduce the harm to human health and the environment, improve the reaction speed and quality, and improve the effect of reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

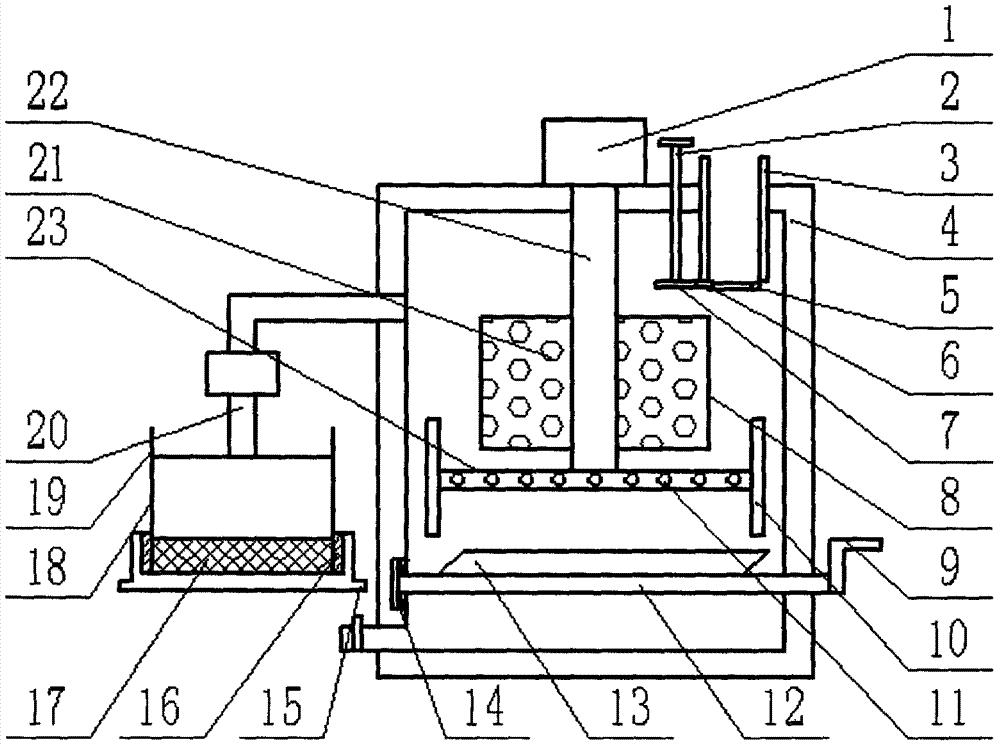

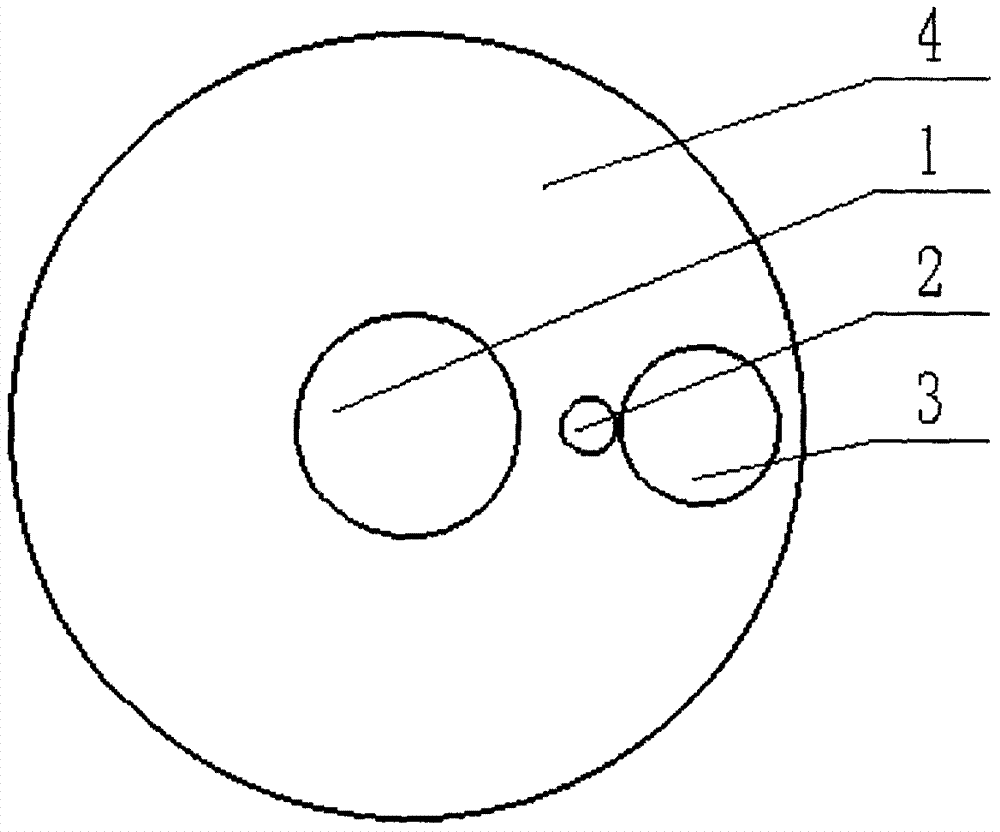

[0017] see Figure 1-2 A chemical reaction kettle with high working quality, comprising a kettle body 4, a drive motor 1 and a filter 18, a drive motor 1 is fixedly installed in the middle of the upper end of the kettle body 4, and the output shaft of the drive motor 1 is connected with a stirring shaft 22; The upper end of the stirring shaft 22 is welded with a stirring plate 8, the bottom end of the stirring shaft 22 is welded with a stirring rod 23, and the two ends of the stirring rod 23 are fixedly connected with a first scraper 10; There is a feeding pipe 3, the bottom end of the feeding pipe 3 is hinged with a baffle plate 5, a driven gear 6 is arranged between the baffle plate 5 and the feeding pipe 3, and a driving gear 7 is meshed on one side of the driven gear 6, and the driving gear 7 is engaged with the driving gear. The upper end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com