Mobile pneumatic paint mixing device

A stirring device, mobile technology, applied in the direction of spraying device, mixer accessories, transportation and packaging, etc., to achieve the effect of preventing paint precipitation, long service life, easy placement and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

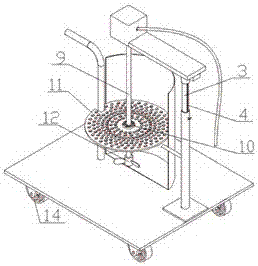

[0044] Rollers are installed at the bottom of the paint bucket, and the column is made of a suitable length in advance according to the height and radius of the paint bucket, so that the air motor is located at a suitable height and above the center of the paint bucket, and the fabricated column is fixed on the outer wall of the paint bucket by welding , fix the filter disc inside the paint bucket, fix the rotating bearing at the center of the filter disc, set the rotating shaft in the rotating bearing, install the air motor at one end of the column in the horizontal direction, and connect it with the rotating shaft and the stirring impeller in turn, and stir The impeller includes 3 impellers, and the angle between each impeller is 120°. The stirring impeller is located at the bottom of the paint bucket, and one end of the paint suction pipe is arranged on the bottom of the paint bucket through the filter plate, and the other end extends out of the bucket, and is connected with ...

Embodiment 2

[0046] Use a mobile trolley, the steel plate thickness of which is 8mm, fix the height-adjustable, horizontally telescopic column on the mobile trolley, fix the paint bucket through the fixed bracket set on the pole, and fix the filter plate inside the paint bucket , fix the rotating bearing at the center of the filter disc, set the rotating shaft in the rotating bearing, install the air motor on one end of the column in the horizontal direction, and connect it with the rotating shaft stirring impeller in turn, the stirring impeller includes 3 impellers, each impeller The included angle is 120°, the stirring impeller is located at the bottom of the paint bucket, one end of the paint suction pipe is installed on the bottom of the paint bucket through the filter plate, and the other end extends out of the bucket to connect with the paint nozzle. After the above components are installed, put the The paint is poured into the paint bucket, and the compressed air hose is connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com