Automatic discharging mini-type mixer

A technology of automatic discharge and mixer, which is applied in mixing plants, cement mixing devices, unloading devices, etc., to achieve the effect of simple structure, reasonable design and uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

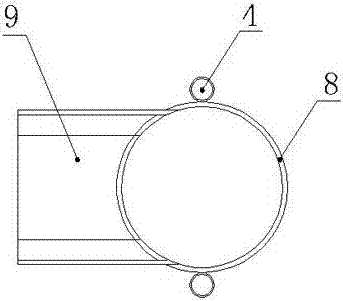

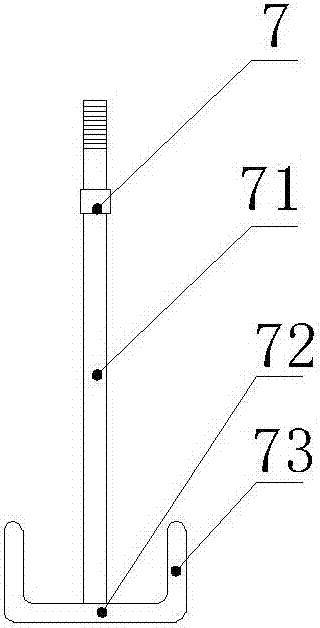

[0014] like figure 1 , 2 , 3, the present embodiment is a kind of automatic discharge micro-mixer, which includes a frame 1, a first fixing device 2, a second fixing device 3, a fixing groove 4, a buckle 5, a driving device 6, and a chevron-shaped agitator 7. Mixing bucket 8, discharge chute 9 and trolley 10, a driving device 6 is fixed on one side of the frame 1, a first fixing device 2 is provided under the top of the driving device 6 on the top of the frame 1, and the first The right side of the fixing device 2 is provided with a buckle 5, the second fixing device 3 is arranged under the first fixing device 2, the mountain-shaped agitator 7 is arranged at the bottom of the driving device 6, and a stirring device is arranged under the frame 1. Bucket 8, the bottom of the frame 1 is fixed to the fixing grooves 4 on both sides of the mixing bucket 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com