Ring jewelry wax machine

A technology for rings and jewelry, which is applied in the field of wax planting machines for ring jewelry, which can solve problems such as unfavorable human health, low efficiency, and damage to human organs, and achieve the effects of improving wax planting efficiency, reducing pollution, and preventing human injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

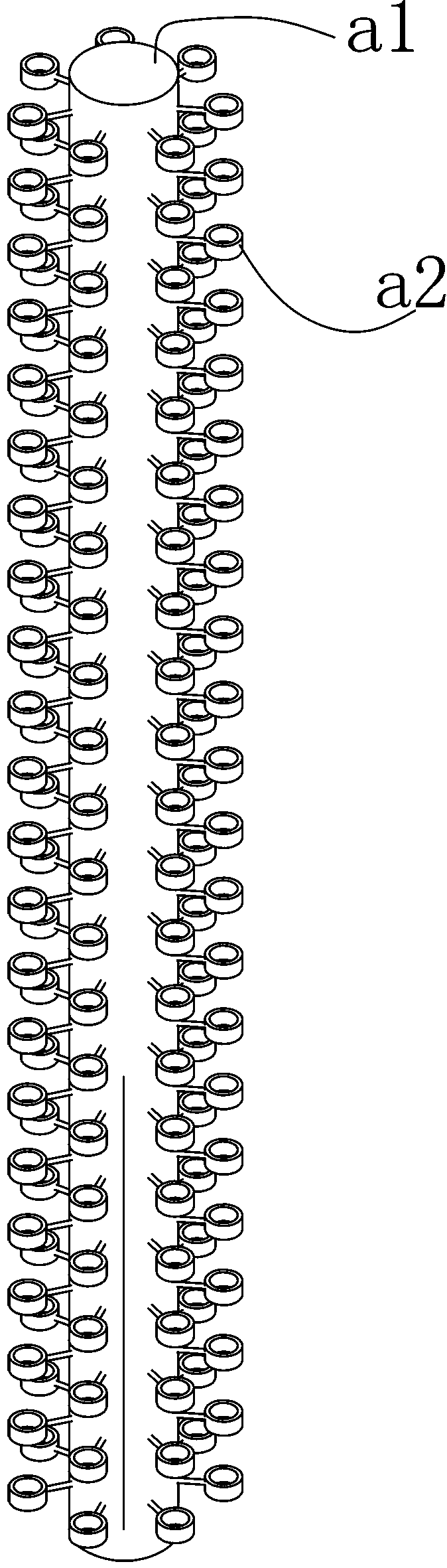

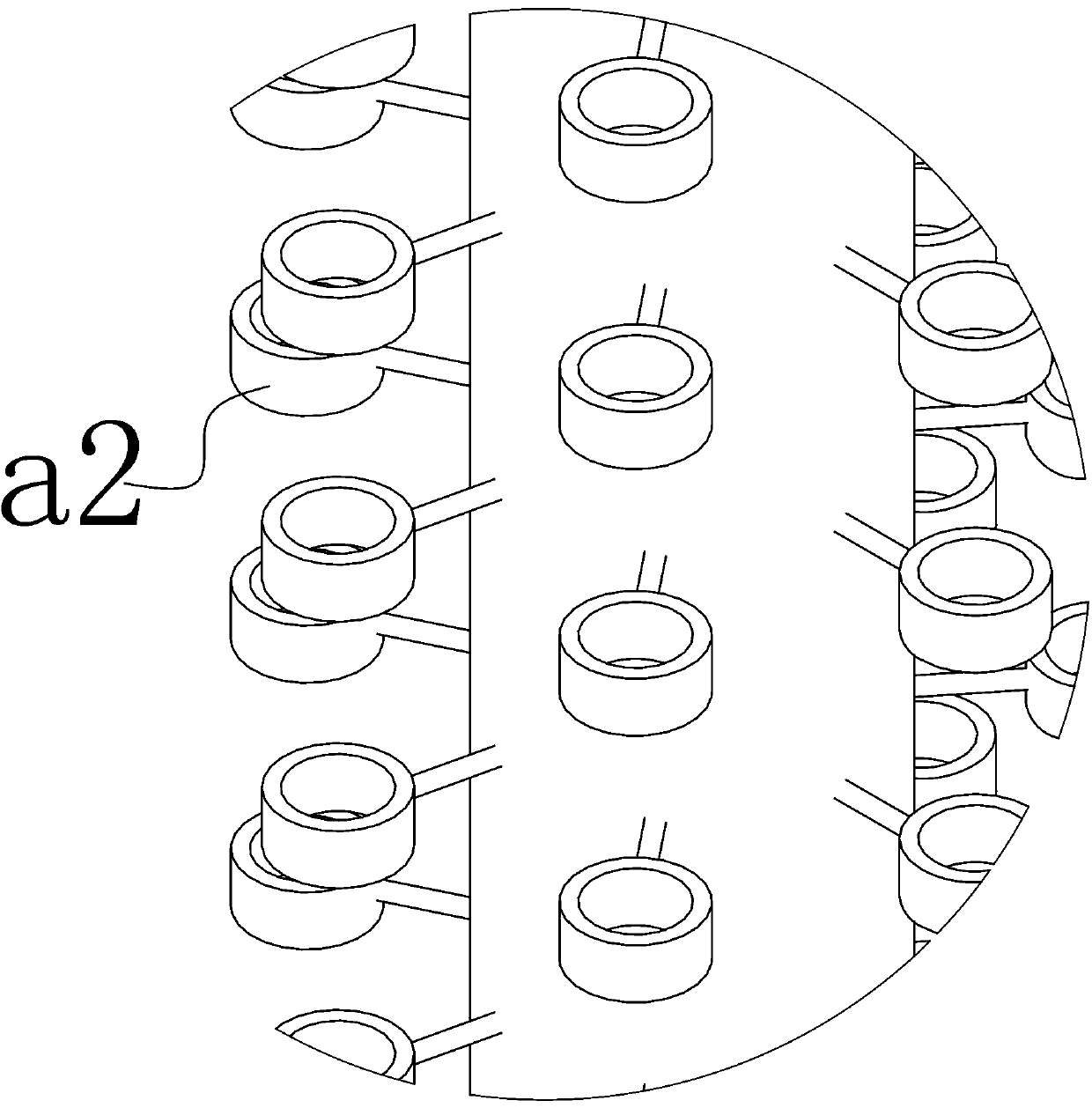

[0028] Such as Figure 1 to Figure 5 As shown, the ring jewelry wax seeding machine described in this embodiment includes a main frame b1, and a wax seeding mechanism fixed on the main frame for seeding wax.

[0029] The kind of wax mechanism includes an extension rod 11 and a first motor 12 that drives the extension rod 11 to rotate. The free end of the extension rod 11 is used to fix the wax stick a1; The mobile moving mechanism also includes a transmission mechanism for transferring the ring wax a2 to the seed wax area; it also includes a welding structure for melting the root of the ring wax a2 and sticking to the wax stick a1. Through the ingenious design of the mechanical structure, the work of wax planting is changed from manual to mechanical, so as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com